A kind of multi-material column CVI furnace and aircraft brake disc manufacturing method

A material column and stockpiling technology, which is applied in the field of multi-material column CVI furnace and aircraft brake disc manufacturing, can solve the problems of large loading capacity, increased equipment maintenance pressure, and blockage of exhaust pipe inlet, and achieve the effect of reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

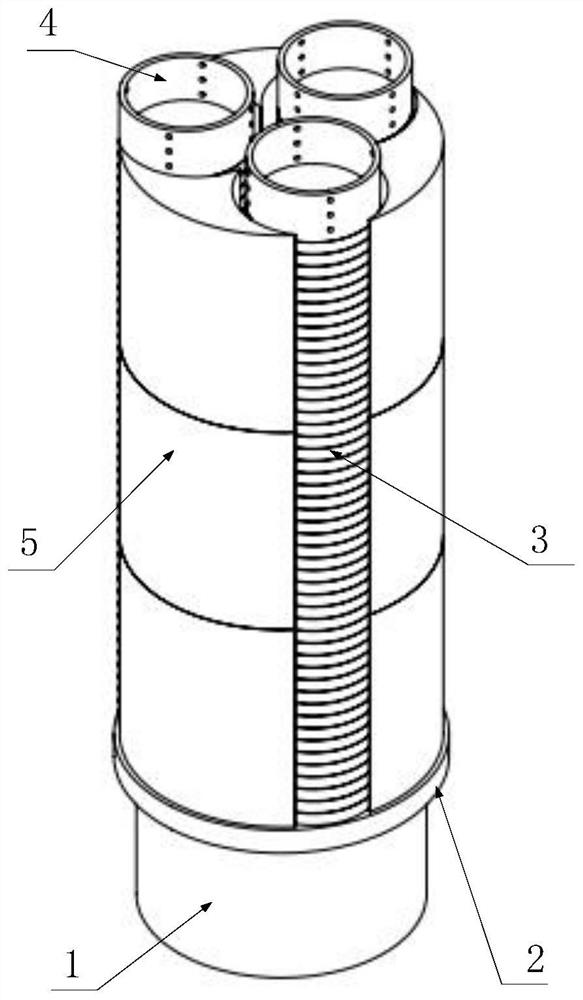

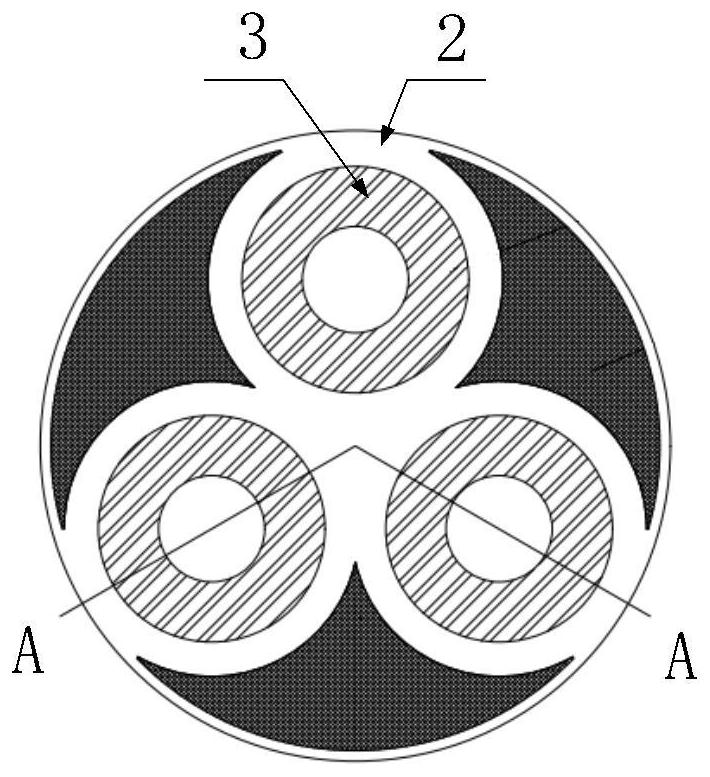

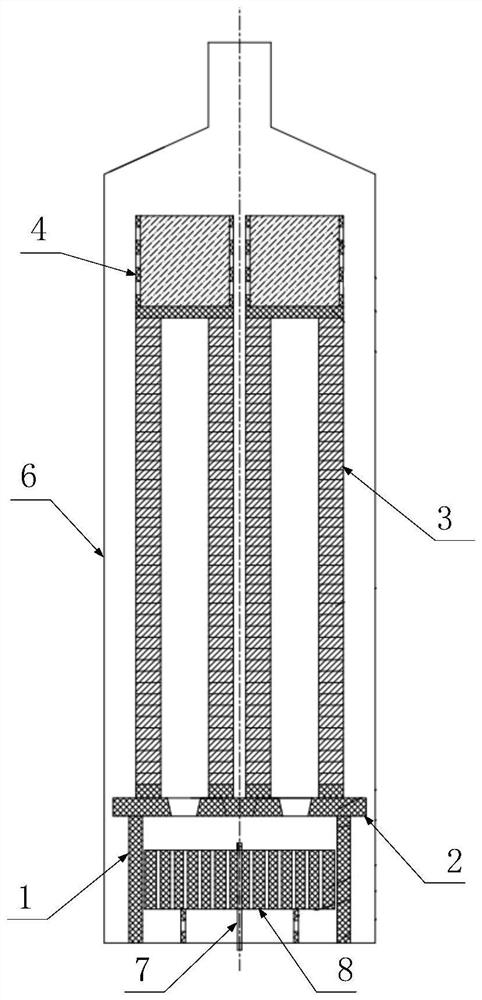

[0021] For ease of understanding, the present invention will be further described below with reference to the accompanying drawings.

[0022] see Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the multi-material column CVI furnace provided by the embodiment of the present invention after the furnace body 6 is omitted, figure 2 Yes figure 1 Schematic cross-section of , image 3 It is the multi-material column CVI furnace edge provided by the embodiment of the present invention. figure 2 Sectional view of section line A-A. It should be noted that the purpose of drawing the material column 3 in the figure is to show the working principle of the multi-material column CVI furnace, and the material column 3 is formed by stacking workpieces (such as aircraft brake disc preforms).

[0023] In the furnace body 6 of the multi-column CVI furnace, the stacking table 2 is arranged on the support base 1, and the stacking table 2 is provided with a plurality of stacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com