A kind of core-shell type Fischer-Tropsch synthesis catalyst and its synthesis method and application

A technology of Fischer-Tropsch synthesis and synthesis method, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of difficult to obtain low-carbon olefins with high selectivity, and achieve the goal of suppressing long-chain hydrocarbons Effects that generate, enhance selectivity, and operate easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Silicone modification:

[0044] Disperse 0.1g tetramethoxysilane with 0.5mL ethanol to obtain a tetramethoxysilane dispersion, add 0.4g iron-based Fischer-Tropsch synthesis catalyst and tetramethoxysilane dispersion to a round bottom flask, mix well, and Place the round bottom flask in a rotary evaporator and rotate at a constant speed, and keep it at 40°C for 0.5h, then raise the temperature by 5°C every 0.5h, keep it at 70°C for 1h, then put the round bottom flask in an oven at 200°C for 10h , to obtain a modified iron-based Fischer-Tropsch synthesis catalyst.

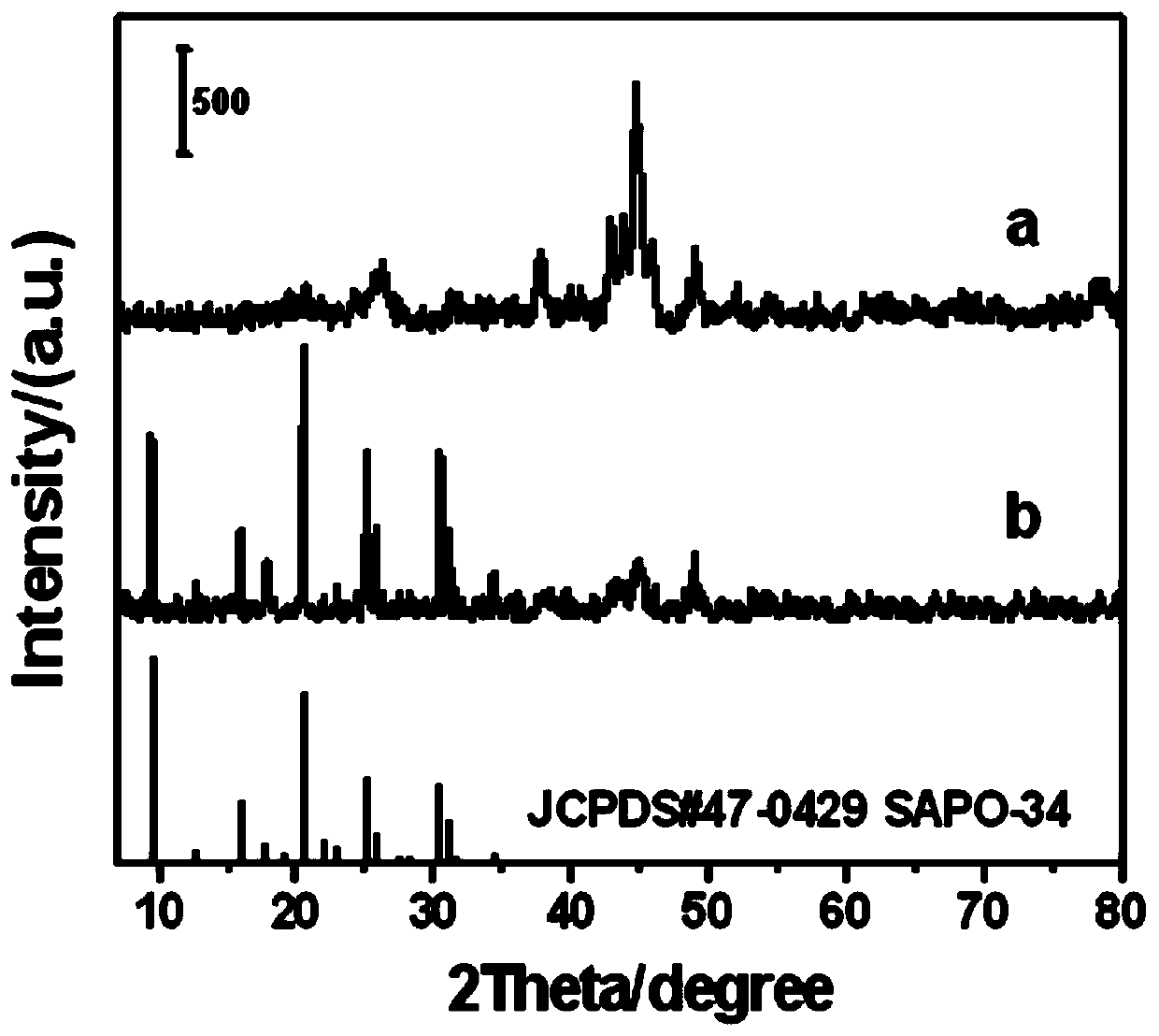

[0045] 2. Preparation of SAPO-34 molecular sieve crystallization liquid:

[0046] Dissolve 2.0g of solid phosphoric acid in 7.8mL of distilled water, then add 1.3g of pseudo-boehmite (Al2 o 3 content of 80wt%), stirred for 2h, then added 2.9g25wt% tetraethylammonium hydroxide aqueous solution, 1.7g morpholine and 1.2g30wt% silica sol, and continued to stir for 5h to obtain SAPO-34 molecular sieve crystall...

Embodiment 2

[0058] 1. Silicone modification:

[0059] Disperse 0.1g tetramethoxysilane with 0.5mL ethanol to obtain a tetramethoxysilane dispersion, add 0.4g iron-based Fischer-Tropsch synthesis catalyst and tetramethoxysilane dispersion into a round bottom flask, mix well, and Place the bottom flask in a rotary evaporator and rotate at a constant speed, and keep it at 40°C for 0.5h, then raise the temperature by 5°C every 0.5h, keep it at 70°C for 1h, then put the round bottom flask in an oven at 200°C for 10h, A modified iron-based Fischer-Tropsch synthesis catalyst is obtained.

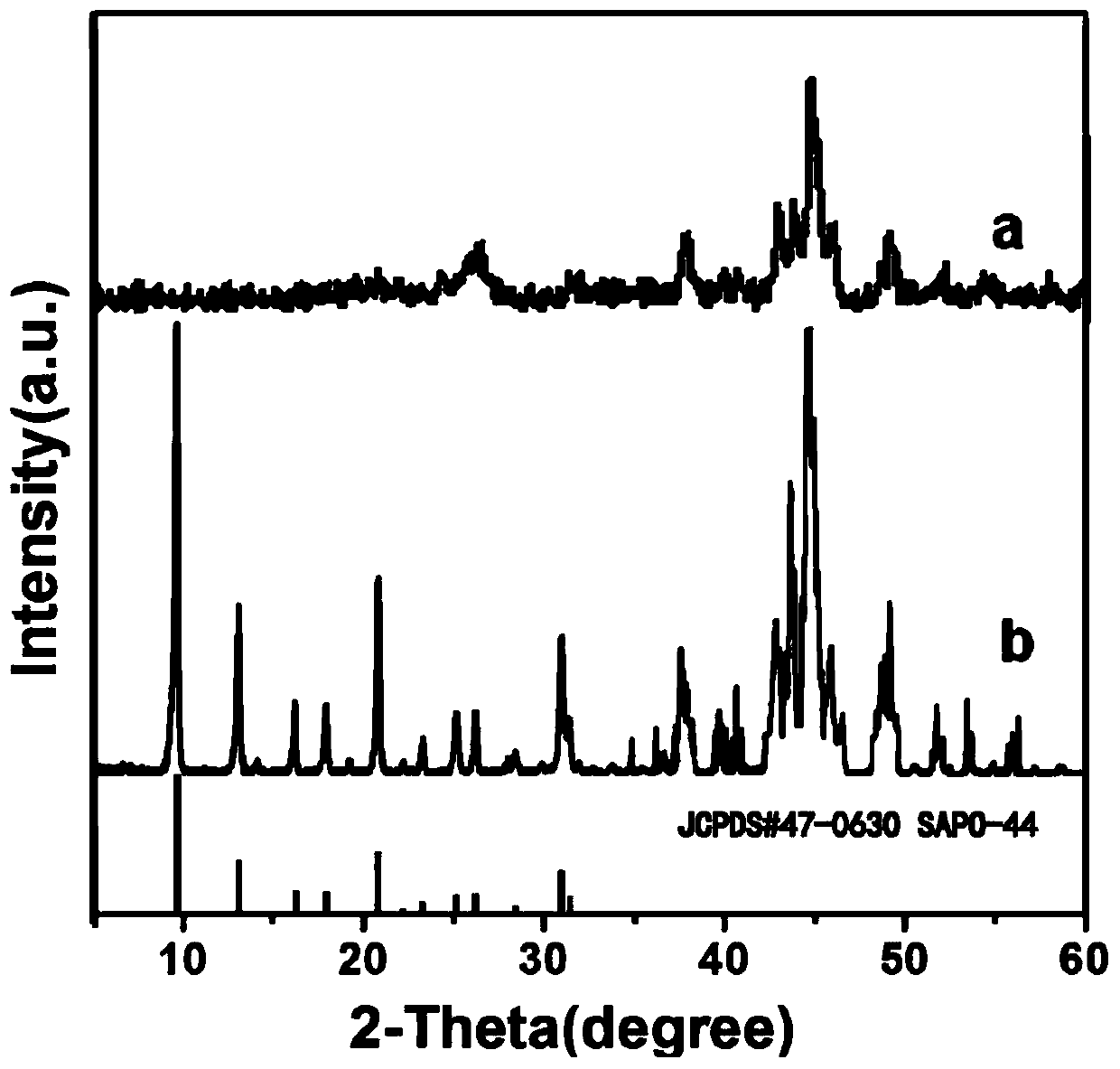

[0060] 2. Preparation of multi-stage porous SAPO-34 molecular sieve crystallization solution:

[0061] Dissolve 2.0g of solid phosphoric acid in 7.8mL of distilled water, then add 1.3g of pseudo-boehmite (Al 2 o 3 content is 80wt%), stirred for 2h, then added 2.9g25wt% tetraethylammonium hydroxide aqueous solution, 1.7g morpholine and 1.2g30wt% silica sol, continued to stir for 5h, then added 0.04g sodium f...

Embodiment 3

[0071] 1. Silicone modification:

[0072] Disperse 0.1g tetramethoxysilane with 0.5mL ethanol to obtain a tetramethoxysilane dispersion, add 0.4g iron-based Fischer-Tropsch synthesis catalyst and tetramethoxysilane dispersion to a round bottom flask, mix well, and Place the round bottom flask in a rotary evaporator and rotate at a constant speed, and keep it at 40°C for 0.5h, then raise the temperature by 5°C every 0.5h, keep it at 70°C for 1h, then put the round bottom flask in an oven at 200°C for 10h , to obtain a modified iron-based Fischer-Tropsch synthesis catalyst.

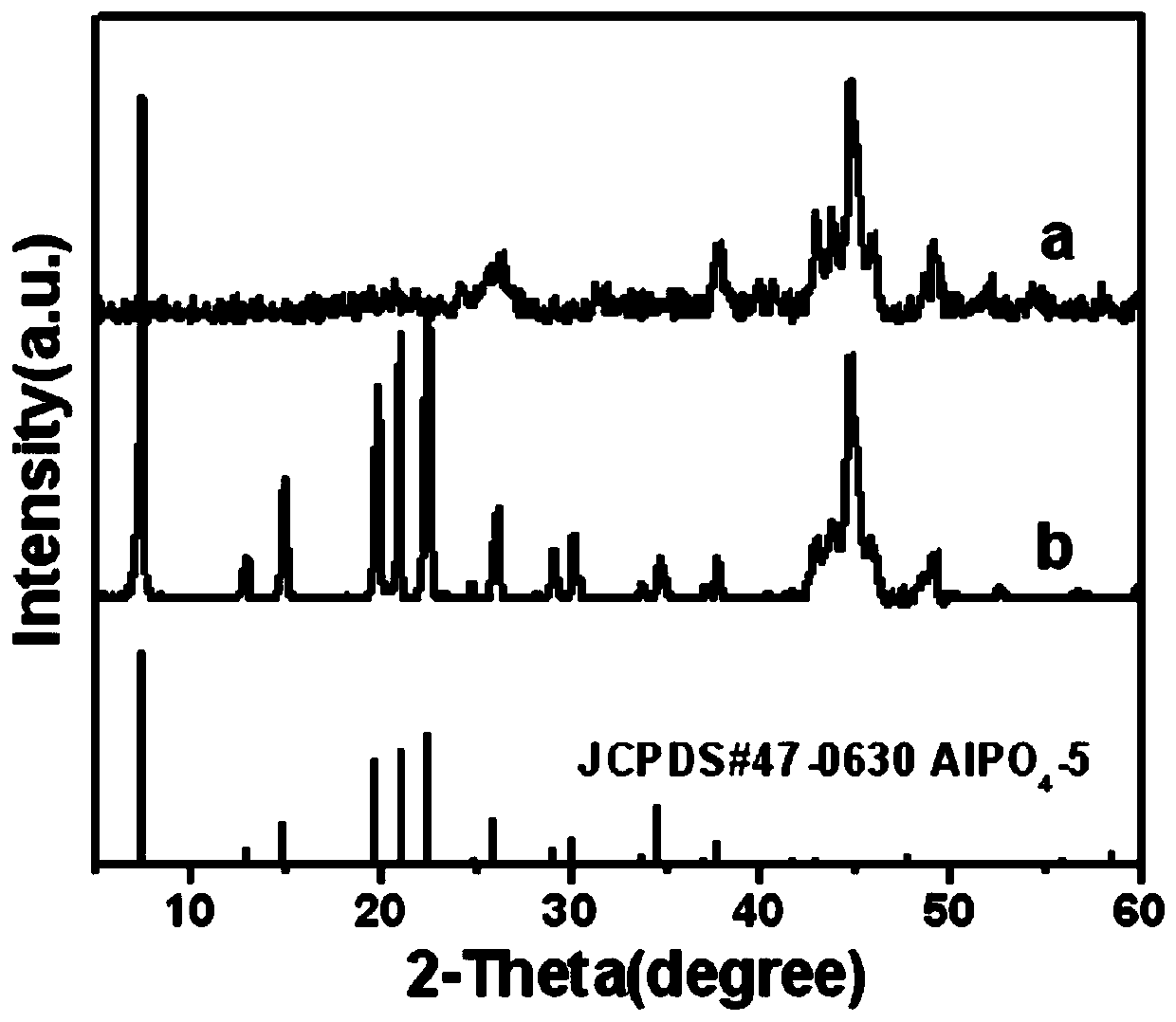

[0073] 2. AIPO 4 Preparation of -5 molecular sieve crystallization liquid:

[0074] Dissolve 2.0g of solid phosphoric acid in 7.8mL of distilled water, then add 1.3g of pseudo-boehmite (Al 2 o 3 The content is 80wt%), stirred for 2h, then added 2.9g25wt% tetraethylammonium hydroxide aqueous solution, 1.7g morpholine, and continued to stir for 5h to obtain AIPO 4 -5 molecular sieve crystallization liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com