Low-viscosity high-solid environment-friendly coating

A high-solid, environment-friendly technology, applied in the field of coatings, can solve the problems of high molecular weight, achieve good drying performance, convenient construction, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

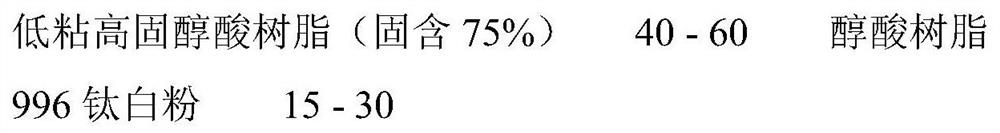

[0016] A kind of low-viscosity high-solid environment-friendly paint, composition and preparation method are as follows:

[0017]

[0018] The solid content of the alkyd resin is high, up to 75-78%, viscosity 28S, Grignard tube, short oil resin is less than 2# iron-cobalt, generally 0-1# (vegetable oil<6#), Medium and long oleoresin is less than 6#.

[0019] The low-viscosity high-solid environment-friendly paint of the present invention, the steps are as follows:

[0020] Add titanium dioxide, phthalocyanine blue BGS, precipitated barium sulfate, and JF-38 bentonite to the mixing disperser according to the above formula, mix and disperse fully to 15μm-25μm, then add low-viscosity high-solid alkyd resin, D40 solvent oil, Rare earth dry material and cobalt dry material are evenly mixed and filtered to obtain the coating.

Embodiment 2

[0022] A kind of hyperbranched epoxy primer, composition and preparation method are as follows:

[0023]

[0024] Preparation method is the same as embodiment 1

[0025] The detection data of the technical solutions recorded in two embodiments of the present invention are as follows:

[0026] project result Apply color and look Uniform, no particles, pinhole bubbles Surface dry time 4-5min Working time / h 2 pencil hardness 3H Cross-cut adhesion / level 0 Impact resistance (kg.cm) 100 Flexibility (cylindrical shaft bending degree) 0.8 Gasoline resistance (10h) pass Oil resistant pass Gasoline resistant pass Diesel resistant pass artificial accelerated aging qualified

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com