Method for preparing high-quality acer truncatum seed oil by supercritical CO2 extraction of unshelled acer truncatum seeds

A technology of maple seeds and maple, which is applied in the field of supercritical CO2 extraction of maple seeds with shells to prepare high-quality maple seed oil, can solve problems such as high cost, low oil yield, and unclear impact, and achieve saving Manpower, material and financial resources, facilitate industrial production, and avoid the effect of shelling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

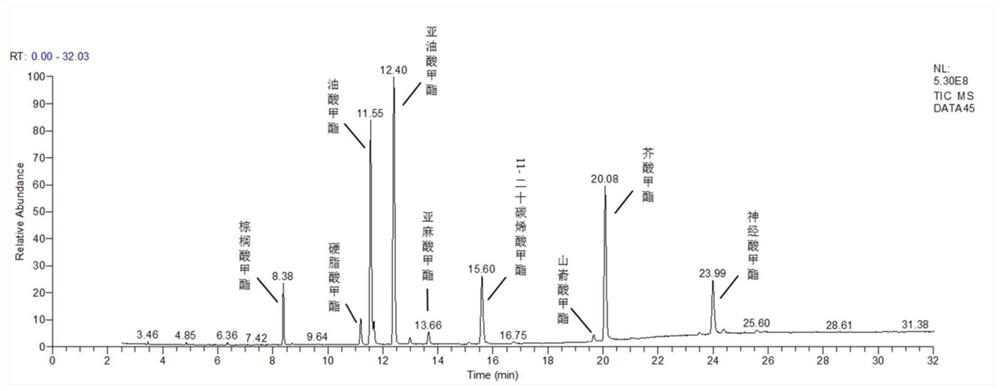

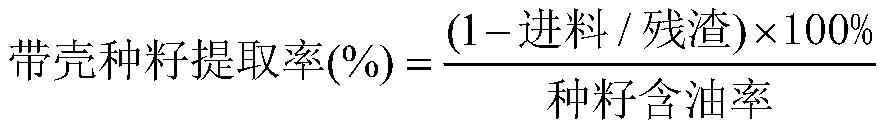

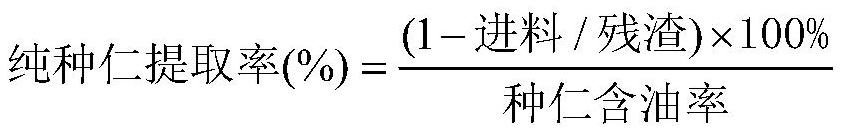

[0024] Accurately weigh 250g of the ingot-shelled maple seed powder (seed moisture content is 6.59%, the same below) in the extraction kettle, adjust the pressure balance, heat the extraction kettle, separation kettle I, and separation kettle II to the set temperature, respectively 35MPa, 55°C, 2h, and at the same time turn on the cooling machine to refrigerate. The extraction kettle, separation kettle I, and separation kettle II are pressurized by a high-pressure pump, the pressures are 35MPa, 7.3MPa, 5.6-6.0MPa respectively, and the total extraction time is set to 2h. After the pressure reaches the set value, the circular extraction starts. After a certain period of time, the materials are discharged from the separation kettle I and the separation kettle II respectively, weighed and the yield is calculated. Supercritical CO in shelled maple ingot seed powder 2 The extraction yield was 92.21%. The physical and chemical indexes of Yuanbao maple seed oil were determined at th...

Embodiment 2

[0027] Accurately weigh 250g of maple ingot shell kernel powder in the extraction kettle, adjust the pressure balance, heat the extraction kettle, separation kettle Ⅰ, and separation kettle Ⅱ to the set temperature, which are 30MPa, 55°C, and 2h, and turn on the cooling machine at the same time . The extraction tank, separation tank I, and separation tank II are pressurized by a high-pressure pump, the pressures are 30MPa, 7.3MPa, 5.6-6.0MPa respectively, and the total extraction time is set to 2h. After the pressure reaches the set value, the circular extraction starts. After a certain period of time, the materials are discharged from the separation kettle I and the separation kettle II respectively, weighed and the yield is calculated. Supercritical CO in shelled maple ingot seed powder 2 The extraction yield was 93.18%. The physical and chemical indexes of Yuanbao maple seed oil were determined at the same time.

[0028] Accurately weigh 165g of the pure-bred kernel powd...

Embodiment 3

[0030] Accurately weigh 250g of maple ingot shell seed powder in the extraction kettle, adjust the pressure balance, heat the extraction kettle, separation kettle Ⅰ, and separation kettle Ⅱ to the set temperature, respectively 35MPa, 60°C, and 2h, and turn on the cooling machine at the same time . The extraction tank, separation tank I, and separation tank II are pressurized by a high-pressure pump, the pressures are 30MPa, 7.3MPa, 5.6-6.0MPa respectively, and the total extraction time is set to 2h. After the pressure reaches the set value, the circular extraction starts. After a certain period of time, the materials are discharged from the separation kettle I and the separation kettle II respectively, weighed and the yield is calculated. Supercritical CO in shelled maple ingot seed powder 2 The extraction yield was 94.85%. The physical and chemical indexes of Yuanbao maple seed oil were determined at the same time.

[0031] Accurately weigh 165g of the pure-bred kernel pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com