Single crystal furnace lifting head mass center dynamic balance mechanism

A technology of balancing mechanism and pulling head, which is applied in the directions of single crystal growth, self-melting liquid pulling method, crystal growth, etc., and can solve the problems of poor stability of single crystal and affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

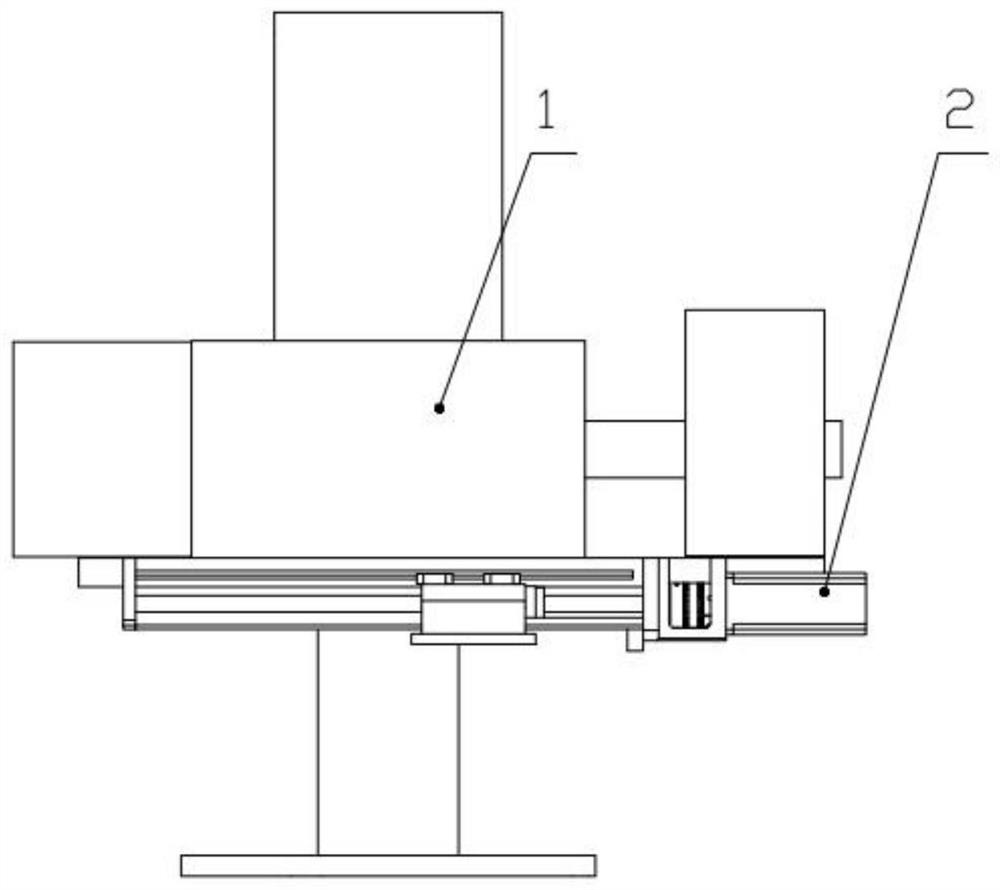

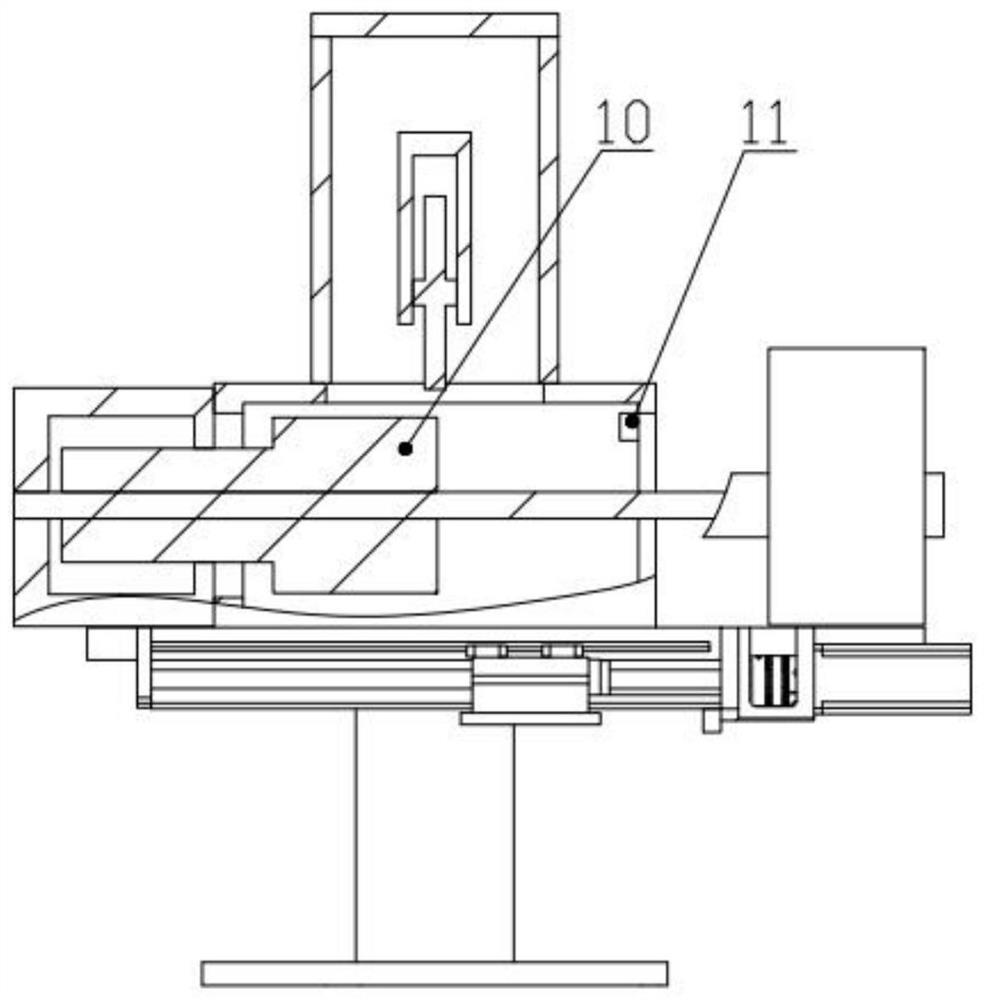

[0017] Such as figure 1 As shown, it includes a lifting head mechanism 1 and a center-of-mass dynamic balancing mechanism 2; the center-of-mass dynamic balancing mechanism 2 is installed on the side of the lifting head sheet, and the pulling head mechanism 1 is equipped with moving rollers for winding tungsten wire ropes

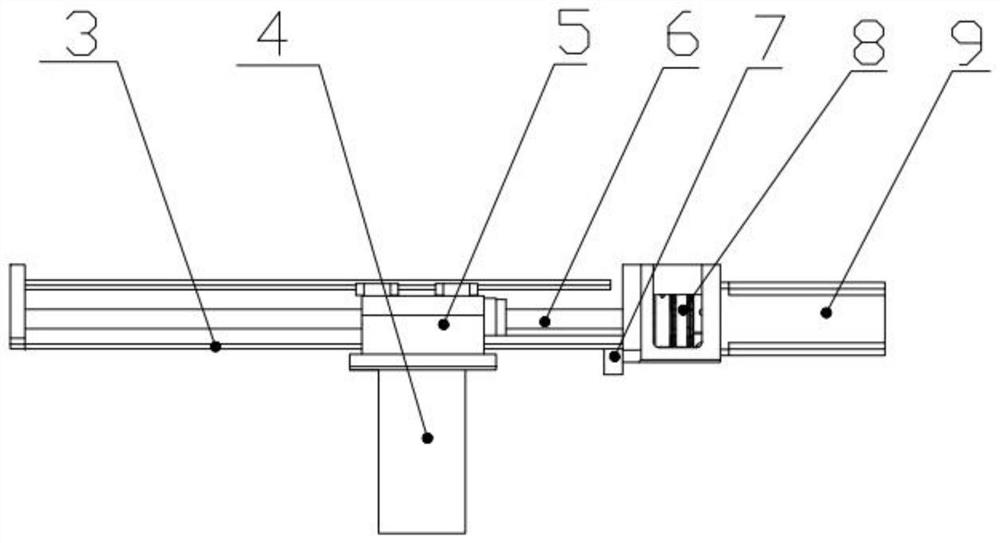

[0018] Such as figure 2 As shown, the center-of-mass dynamic balance mechanism 2 is controlled by an electronic control system, including a motor 9, a coupling 8, a position sensor 7, and a linear guide slide module 6. The linear guide slide module includes a transmission structure base 3 and a slider 5 and linear guides6. The motor 3 is installed on one end of the base 3 of the transmission structure, and drives the slider 5 on the linear guide rail 6 to perform linear reciprocating motion through the coupling 8. The slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com