Totally-enclosed calibratable magnetic ring impedance measurement clamp and magnetic ring impedance measurement method

An impedance measurement, fully enclosed technology, applied in the direction of measuring electrical variables, measuring devices, measuring device casings, etc., can solve problems such as difficulty in ensuring the consistency of coil connections, affecting the consistency and stability of measurement results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, further describe the present invention in detail through embodiment.

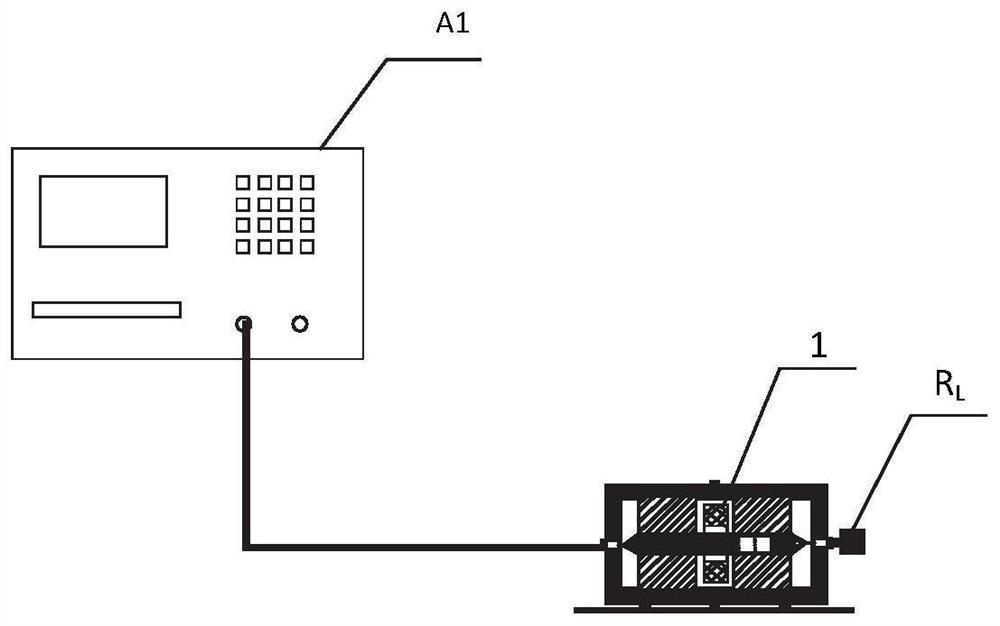

[0042] A test layout for one embodiment of the present invention is as figure 2 Shown, where 1 is the magnetic ring to be tested, A1 is the network analyzer, R L for matching resistors. Before taking measurements, press the figure 2 As shown, connect the network analyzer to one end of the measurement fixture, connect the other end of the fixture to the calibration kit (short circuit, open circuit, and matching), and perform a single-port calibration on the measurement fixture. After the calibration, the other end of the fixture is connected to a matching resistor.

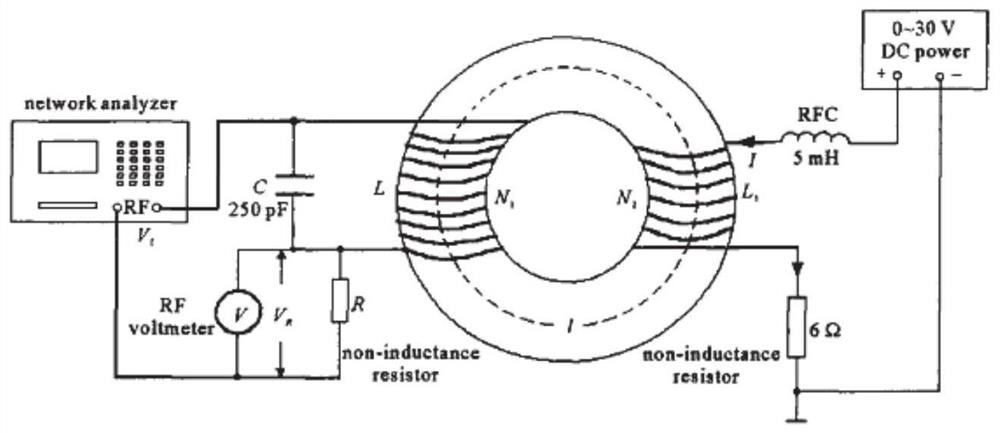

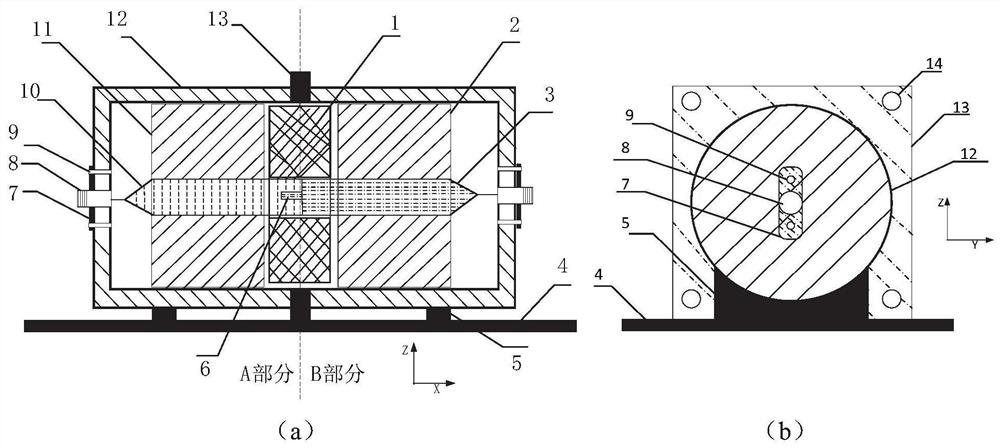

[0043] like image 3 The measuring fixture of an embodiment shown is mainly composed of a metal shell, a cylindrical polytetrafluoroethylene insulating support with a round hole in the middle of the metal shell, a metal coaxial core wire, etc., and the whole is a coaxial structure. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com