Method, device, equipment and storage medium for detecting missing welding defects of leds

A detection method and defect detection technology, applied in measurement devices, optical testing flaws/defects, image enhancement, etc., can solve problems such as difficulty in ensuring product quality consistency, reducing the clarity of welding lines and solder joints, and unqualified LED products. , to achieve the effect of ensuring product quality consistency, preventing interference, and eliminating the influence of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In view of the above problems, the embodiment of the present application provides a detection method for missing soldering defects of LEDs, which can accurately and objectively detect the missing soldering defects of LEDs.

[0053] The technical solutions of the embodiments of the present application are described in detail below with reference to the accompanying drawings.

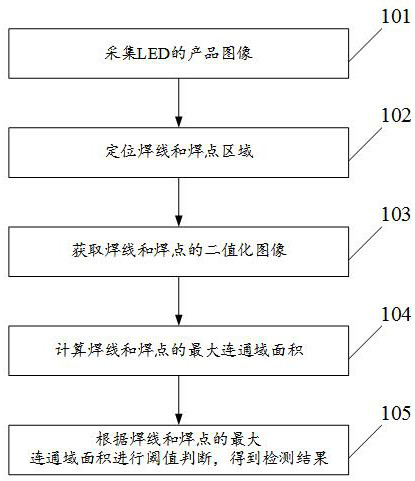

[0054] figure 1 It is a schematic flowchart of a detection method for missing soldering defects of LEDs shown in an embodiment of the present application.

[0055] see figure 1 , the detection method of the missing welding defect of described LED, comprising:

[0056] 101. Collecting LED product images;

[0057] In the embodiment of the present application, the product image of the LED may be a single product image or an entire product image. If the entire product image is collected, the product image is identified and segmented to obtain a single product image, and then step 102 is performed.

...

Embodiment 2

[0098] The embodiment of the present application designs step 102 in the above-mentioned embodiment 1.

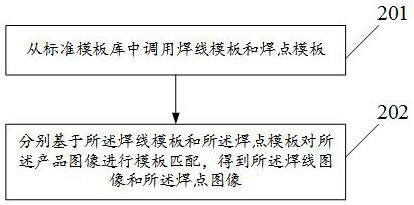

[0099] figure 2 It is a schematic flowchart of a method for positioning welding wires and welding spot regions shown in the embodiment of the present application.

[0100] See details figure 2 , the positioning method of the welding line and the welding point area, comprising:

[0101] 201. Call the welding line template and the welding spot template from the standard template library;

[0102] In the embodiment of the present application, the standard template library may contain various types of LED product templates, and the LED product templates are positioning data obtained by pre-processing according to LED product samples.

[0103] It should be noted that the above description of the standard template library is only an example in the embodiments of the present application, and should not be regarded as a limitation of the present invention.

[0104] 202. Perfo...

Embodiment 3

[0109] In this embodiment of the present application, step 103 in the above-mentioned embodiment 1 is designed.

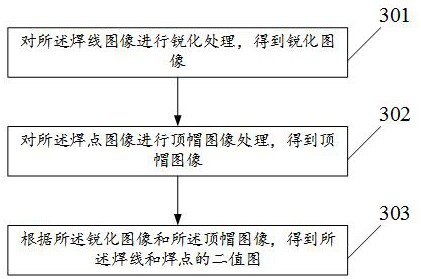

[0110] image 3 It is a schematic flowchart of a method for obtaining a binary image of welding wires and welding spots shown in the embodiment of the present application.

[0111] See details image 3 , the method for obtaining the binary image of the welding wire and the welding spot, comprising:

[0112] 301. Perform sharpening processing on the welding line image to obtain a sharpened image;

[0113] In the embodiment of the present application, the purpose of performing sharpening processing on the welding line image is to highlight the features of the welding line, so as to separate the welding line from the background during subsequent binary image processing.

[0114] It should be noted that there is no strict limitation on the sharpening method used in the embodiment of the present application. In the actual application process, any image sharpening alg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com