Alloy type thermal fuse link for rapid fusing of LED lamp

A thermal fuse, LED lamp technology, applied in thermal switches, thermal switch parts, heating/cooling contact switches, etc., can solve the problems of difficult control of the production process, separation of the installation surface of thermal components, long curing time, etc. achieve the effect of protecting the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

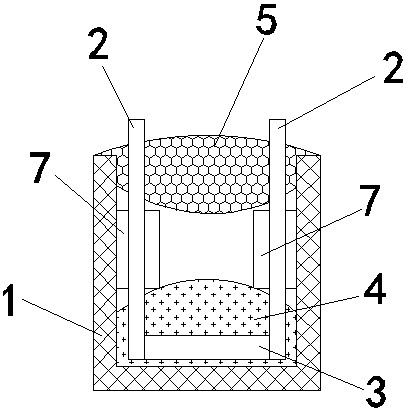

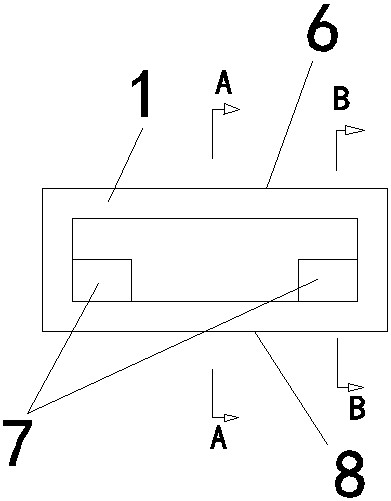

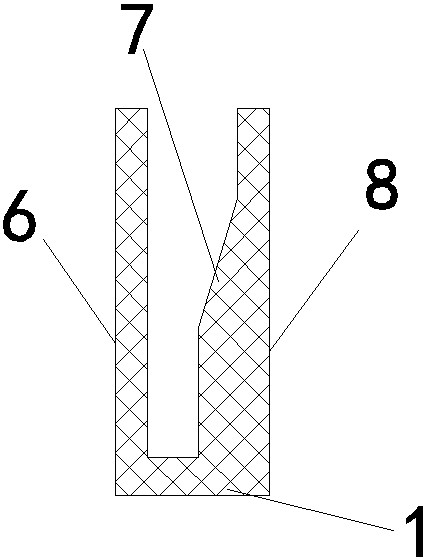

[0034] The technical solutions of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings and embodiments.

[0035] See attached Figure 1-6In the thermal fuse, trapezoidal wedges 7 are respectively arranged on both sides of the inner wall of the identification surface 8 of the housing 1, and two lead wires 2 are respectively inserted between the two trapezoidal wedges 7 and the inner wall of the mounting surface 6 of the housing 1, and the two lead wires One end of 2 is welded by heating element 3 and overlapped, and flux 4 is filled around heating element 3, one side of heating element 3 is in direct contact with the inner wall of mounting surface 6 of shell 1, and the other end of lead wire 2 extends out of the shell The body 1 and the opening of the housing 1 are sealed with epoxy glue 5 .

[0036] The two trapezoidal wedges 7 in the housing 1 of the thermal fuse are located on one side of the inner markin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com