Steel shell button cell heat sealing mold and manufacturing method

A button battery and heat sealing technology, which is applied in secondary battery manufacturing, electrolyte storage battery manufacturing, primary battery, etc., can solve problems such as high scrap rate, seal cracking, and electrolyte outflow, so as to improve yield rate and production efficiency, The effect of improving sealing performance and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

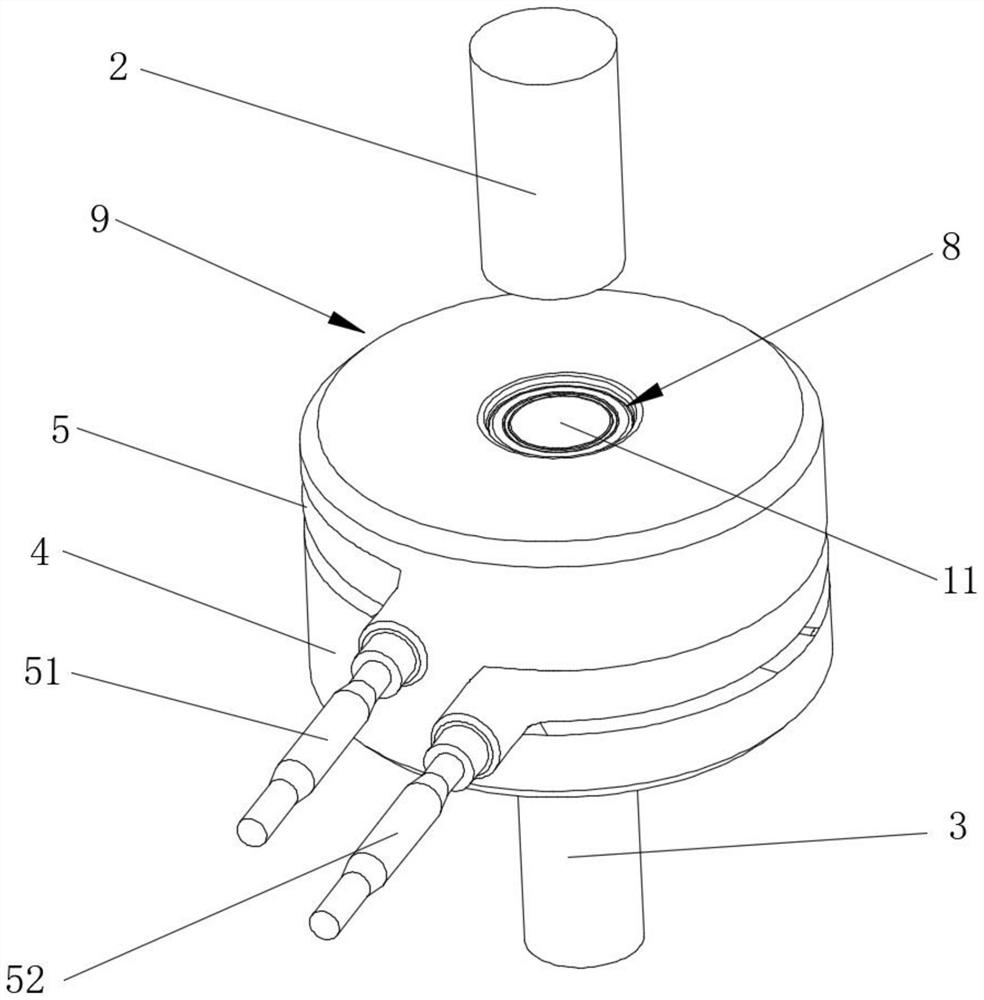

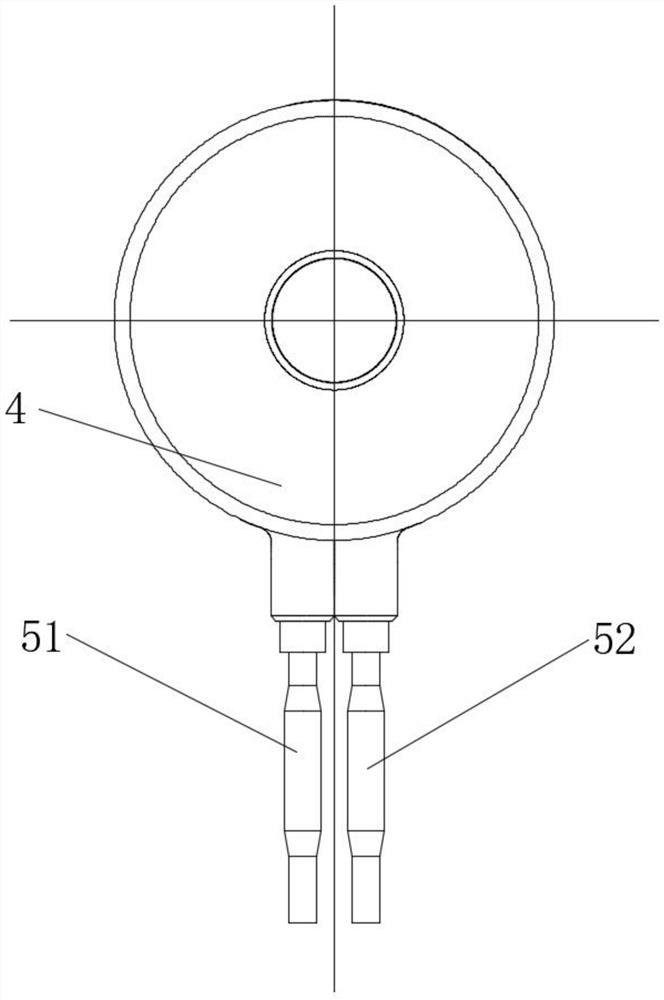

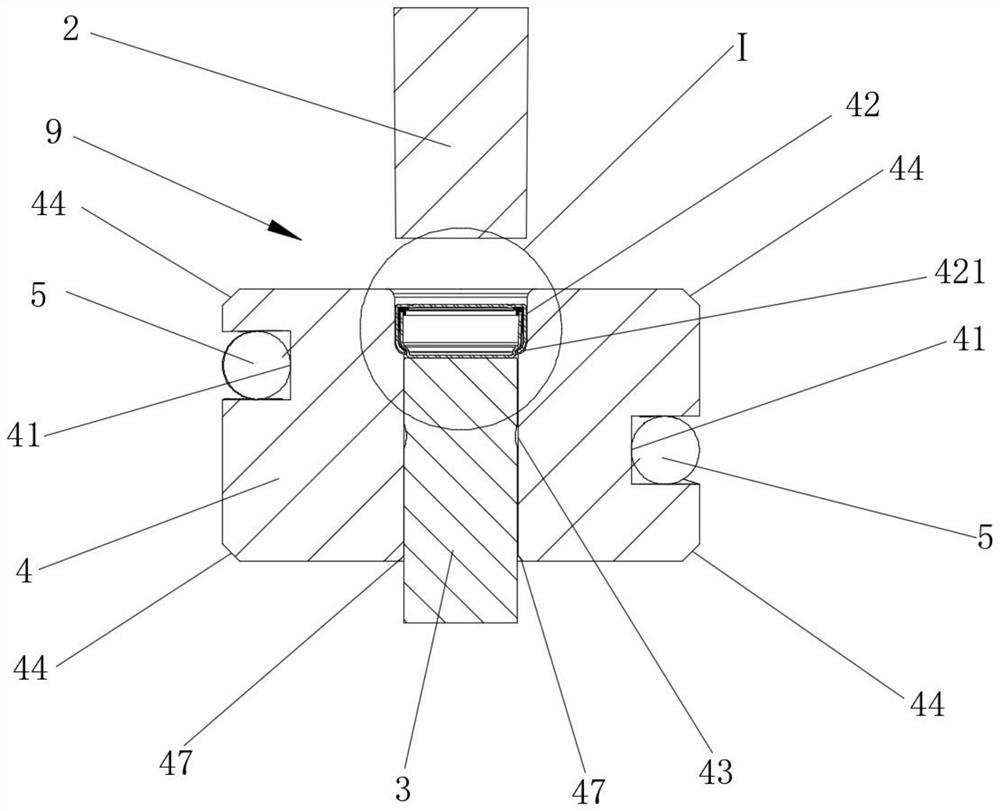

[0031] Please refer to Figure 1 to Figure 6 , Embodiment 1 of the present invention provides a heat-sealing mold for a steel case button battery, the heat-sealing mold 9 includes an upper die 2 for sealing the positive case 11 and a lower die for sealing the negative case 12 3. The upper top mold 2 is connected to the press. When working, the upper top mold 2 moves downward, and the lower top mold 3 does not move. Between the upper top mold 2 and the lower top mold 3 A sealing die 4 is installed, and the heat-sealing action of the steel shell button battery 8 is carried out inside the sealing die 4, such as image 3 As shown, the outer side of the sealing mold 4 is provided with a groove 41, and the inside of the groove 41 is equipped with a heating device 5 for heating the sealing mold 4, and the heating device 5 is controlled by a temperature controller module, controlled by a temperature controller The device module controls the heating device 5 to reach the appropriate t...

Embodiment 2

[0037] Such as Figure 7 As shown, Embodiment 2 of the present invention provides a method for manufacturing a steel case button battery with a heat sealing mold for a steel case button battery, comprising the following steps:

[0038] Step S1, manufacturing the positive electrode casing 11 and the negative electrode casing 12; stamping and forming the steel foil with a thickness of 2-3mm using a specific production mold, so that the positive electrode casing 11 and the negative electrode casing 12 have the same characteristics as the positive electrode sheet and the negative electrode casing 12. Grooves for the negative electrodes to fit into each other, and the openings have bent edges that can be engaged with each other;

[0039] Step S2, manufacturing the positive electrode sheet and the negative electrode sheet; coating the positive electrode slurry on the positive electrode current collector, coating, molding and drying, punching it into a corresponding shape with a punc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com