Batch reactor

A reactor and batch technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, mixers, etc., can solve problems such as temperature deviation and adverse effects on final product quality, to ensure particle stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

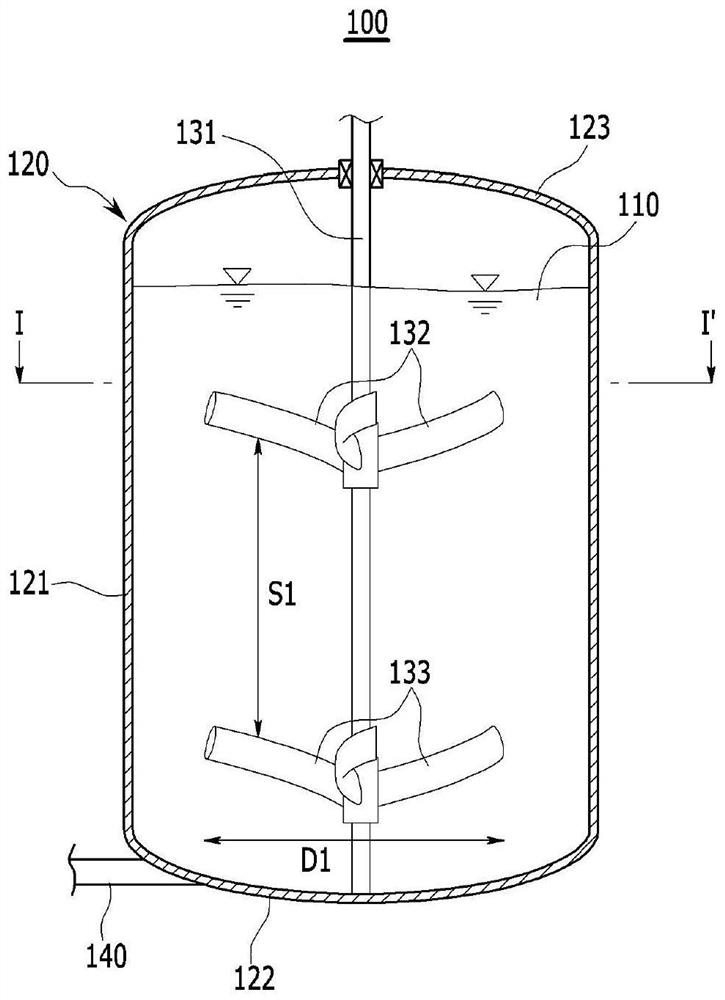

[0057] Reactant 110 is charged as attached figure 1 The shown batch reactor 100 comprising two curved impellers 132 and 133 was then stirred at a power of 110 W and a speed of 315 rpm. Reactant 110 is 50.5% by weight vinyl acetate ethylene (VAE), 0.1% by weight polyvinyl alcohol (PVA), 2.1% by weight vinyl acetate monomer (VAM), 0.5% by weight ethylene and 42.4% by weight Distilled water, ethylene are supplied through supply nozzles 140 connected to the bottom 122 . The rotation diameter (D1) of the curved impellers 132 and 133 is 0.2 m, and the distance S1 between the curved impellers 132 and 133 is 0.6 m. The ratio of the spacing S1 between the curved impellers 132 and 133 to the rotation diameter D1 of the curved impellers 132 and 133 is three. The cylindrical reactor body 120 has a height-to-diameter ratio of 2, and the temperature in the batch reactor 100 is maintained at 80°C and the pressure is maintained at 80 bar(g).

Embodiment 2

[0068] Evaluation Example 2: Mixing Time

[0069] In order to compare the mixing efficiency in the VAE polymerization reaction, the mixing times of Example 1 and Comparative Example 2 were measured and shown in Table 2 below. In Table 2, S / D refers to the ratio of the pitch between the curved impellers to the rotational diameter of the curved impellers.

[0070] Table 2

[0071] Number of curved impellers S / D Mixing time (sec) Example 1 2 3 74 Comparative example 2 3 1.5 153

[0072] It can be confirmed from Table 2 that in the case of Comparative Example 2, since the ratio of the distance between the curved impellers to the rotational diameter of the curved impellers is less than 2, although the number of curved impellers is large, compared with Example 1, the measured The mixing time is significantly increased.

Embodiment 3

[0073] Evaluation Example 3: Gas holdup

[0074] In order to compare the reaction rate in the VAE polymerization, the gas holdups of Example 1 and Comparative Example 1 were measured and shown in Table 3 below, and the gas holdups of Example 1 and Comparative Example 3 were measured and shown in the table below 4 in.

[0075] table 3

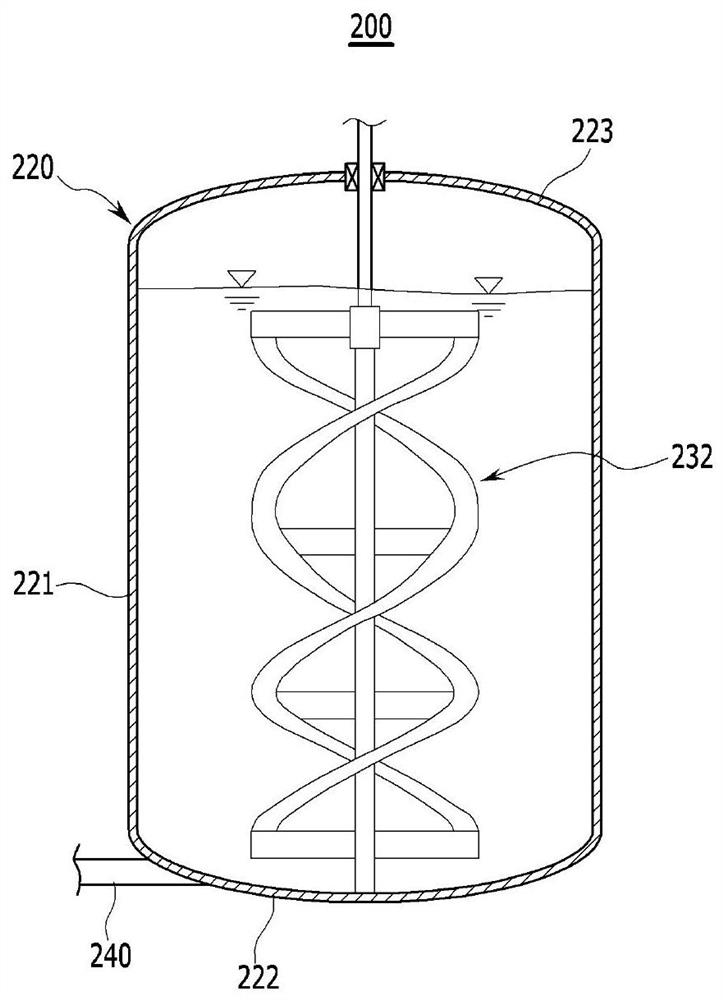

[0076] impeller type Gas holding rate (%) Example 1 curved impeller 5.6 Comparative example 1 rotating belt 4.2

[0077] From Table 3, it can be confirmed that the curved impeller of the present disclosure exhibited a higher polymerization reaction rate of VAE compared to the helical ribbon impeller.

[0078] Table 4

[0079] Air supply nozzle position Gas holding rate (%) Example 1 bottom 5.6 Comparative example 3 Lower end of side wall 5.3 Comparative example 3 Middle end of side wall 5 Comparative example 3 upper end of side wall 4

[0080] From Table 4, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com