Moving magnetic pole permanent magnet separator

A technology of magnetic separator and moving magnetic pole, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of complex equipment structure, influence on concentrate grade, electromagnetic conversion and control mechanism prone to failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

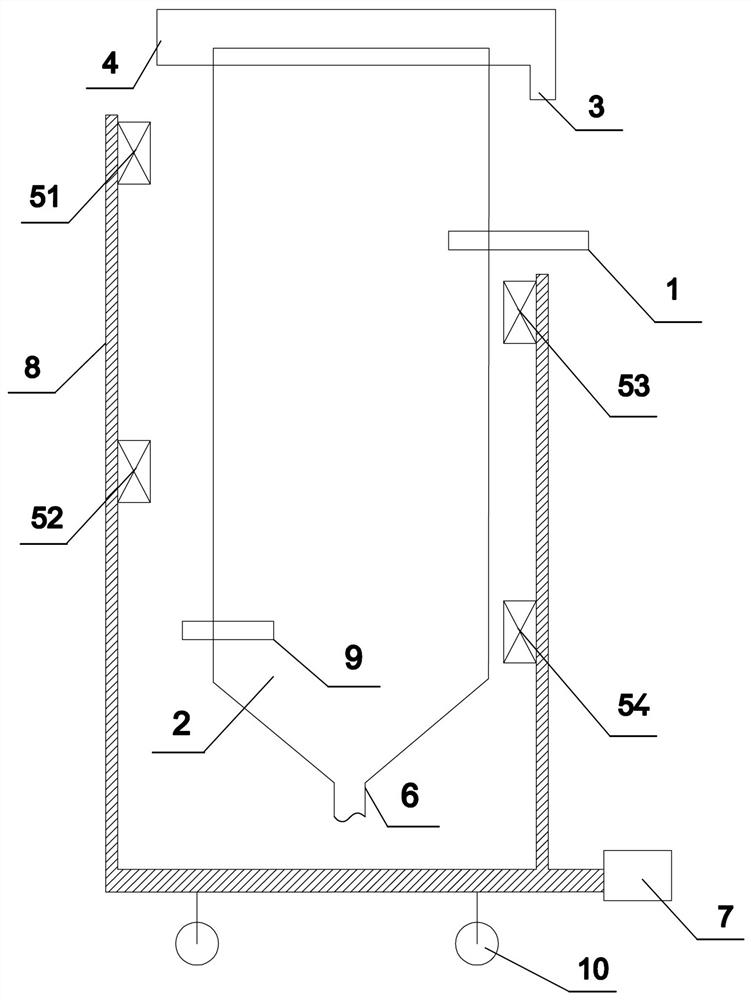

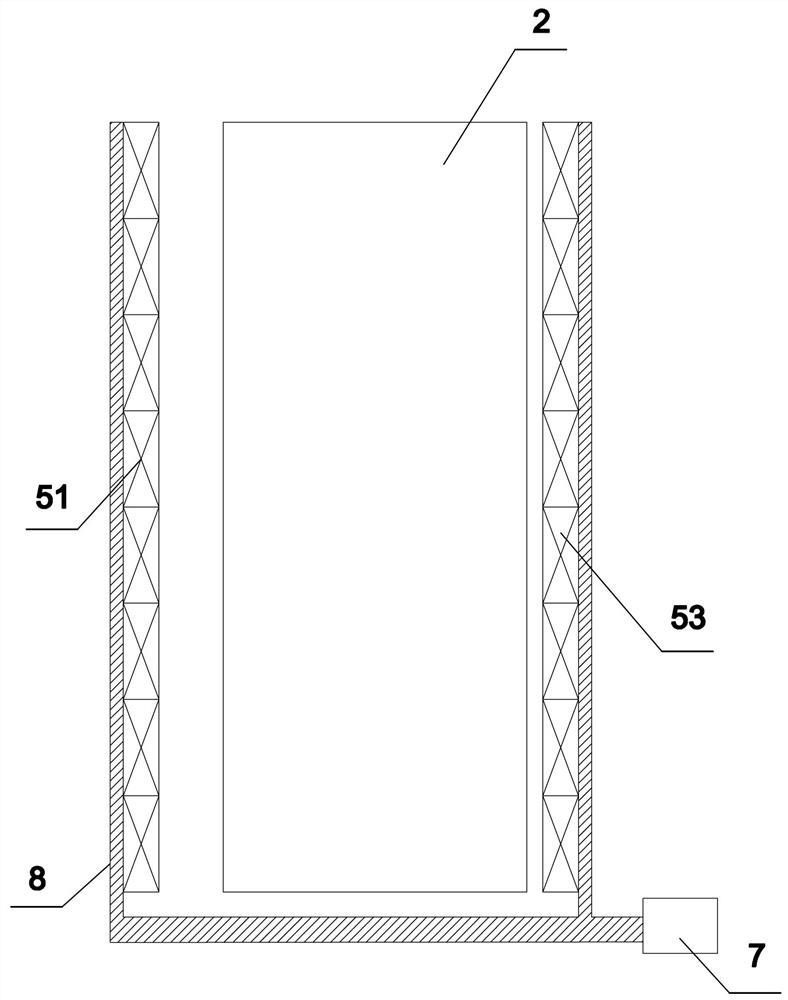

[0016] Such as figure 1 and figure 2 As shown, a kind of moving magnetic pole permanent magnet magnetic separator of the present invention comprises sorting chamber 2, ore supply pipe 1, water supply pipe 9, tailings overflow tank 4, tailings discharge pipe 3, concentrate discharge pipe 6. Two-layer magnetic system, magnetic system bracket 8 and linear motor 7, characterized in that the upper part of the separation chamber 2 is an open box, the lower part is a quadrangular pyramid, and the upper part of the open box is The periphery is fixedly connected with the tailings overflow tank 4, the tailings discharge pipe 3 is connected at the bottom of the lower end of the tailings overflow tank 4, and the concentrate discharge pipe 6 is connected at the bottom of the quadrangular pyramid. The layer magnetic system is arranged on both sides of the outside of the separation cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com