Automatic duster for thermally conductive silicone cloth

A heat-conducting silicon and powder-spraying technology is applied to devices and coatings that apply liquid to the surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present application will be further described in detail below with reference to the accompanying drawings.

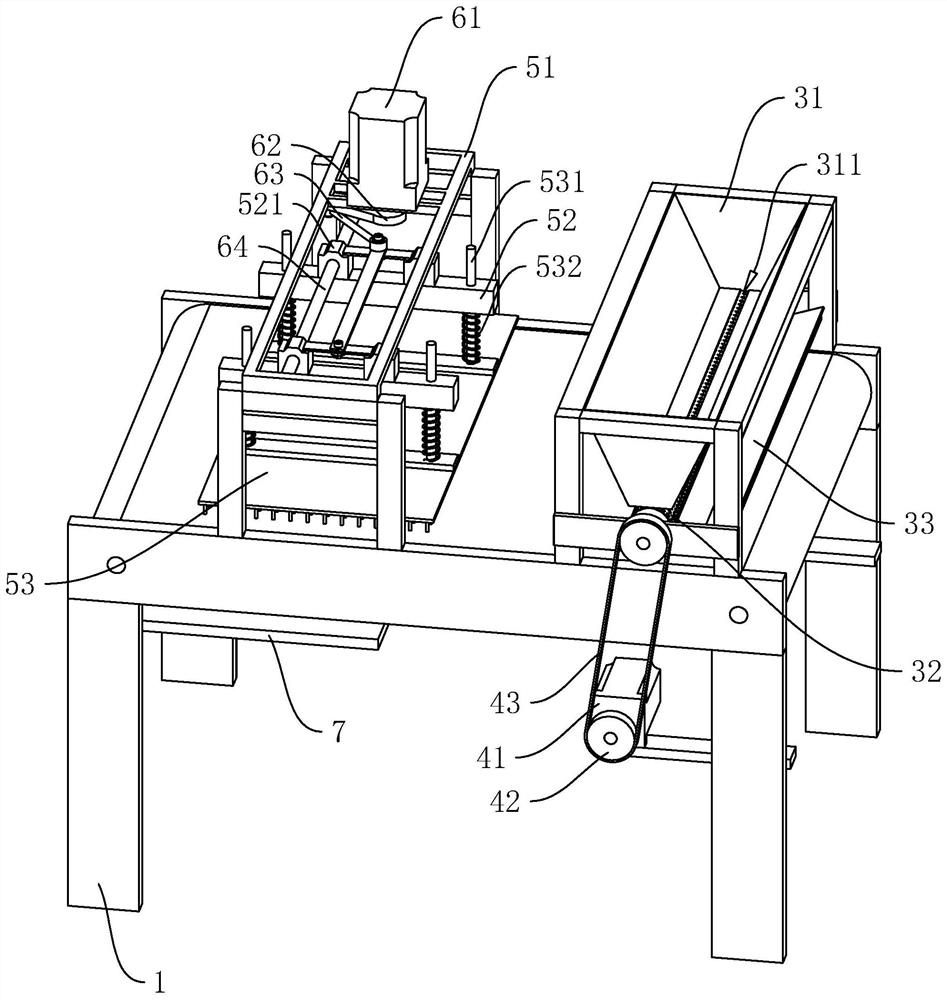

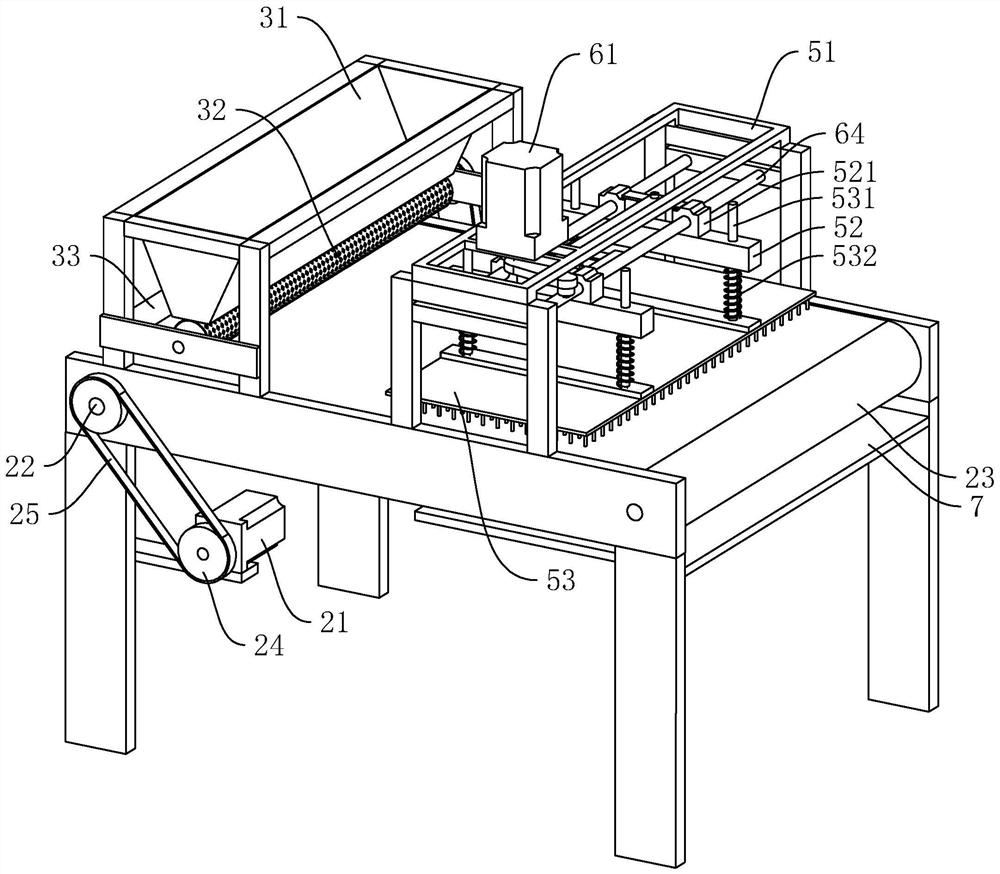

[0036] The embodiment of the present application discloses an automatic duster for thermally conductive silica gel cloth. refer to figure 1 , The automatic duster for thermally conductive silicone cloth includes a frame 1, a transmission mechanism installed on the frame 1 for conveying the thermally conductive silicone cloth, and a dusting mechanism installed on the frame 1 and located above the transmission mechanism.

[0037] The dusting mechanism includes a powder box 31 installed horizontally on the frame 1, a coating roller 32 horizontally installed under the powder box 31, and a drive assembly for driving the coating roller 32 to rotate. The two ends of the coating roller 32 are respectively The horizontal rotation is connected to both sides of the mounting bracket 51 . The powder box 31 is used for containing mica powder. The bottom of the powder box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com