A kind of thermosetting high temperature resistant touch screen ink and preparation method thereof

A high-temperature-resistant, touch-screen technology, applied in ink, household utensils, applications, etc., can solve the problems of easy yellowing or cracking of the coating, and limit the sensitivity of the touch screen, and achieve good color retention, no cracks, and coating Membrane Intact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

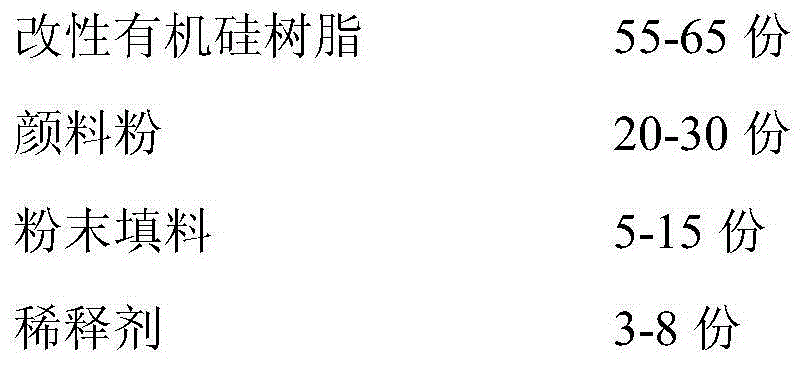

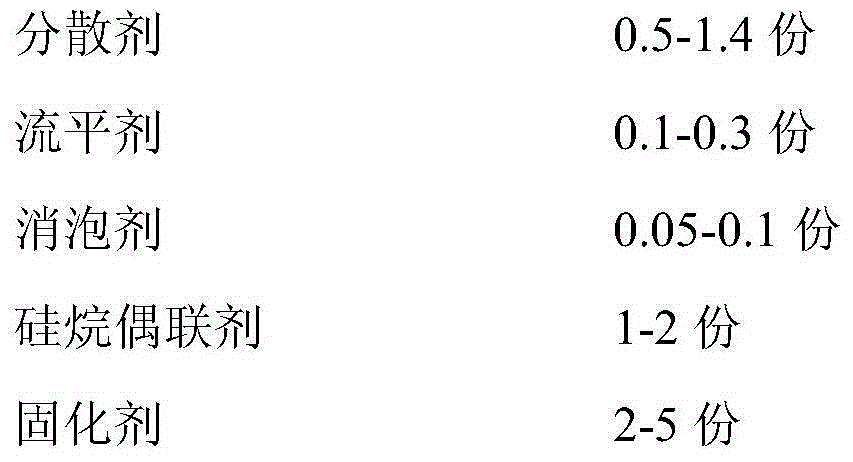

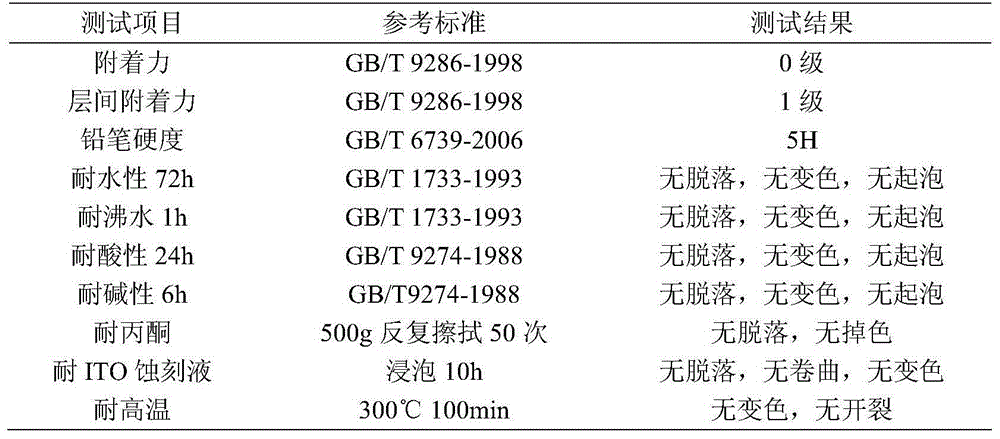

Method used

Image

Examples

Embodiment 1

[0034] 1) Take 55 polyester modified silicone resin JY7200 (Dongguan Junyi Chemical Technology Co., Ltd.), 20g Tupont902 + Titanium dioxide (DuPont), 3g glass powder, 2g nano silicon dioxide, 1g isophorone, 1g No. 200 solvent oil, 0.3g BYK110 dispersant (BYK additive), 0.1g AFCONA3670 leveling agent (Efcona Chemical), add it into the dispersion tank, stir evenly, grind and disperse for 90min with a grinder at 2500rpm, and filter to obtain the main ingredient;

[0035] 2) Take 1g CYMEL303, 1g CYMEL325 crosslinking agent (Weng Kaier Co., Ltd.), 2g cyclohexanone, 0.5g KH550 coupling agent, 0.5g A187 coupling agent, 0.2g AFCONA-5010 dispersant (Efcona Chemical), 0.1g AFCONA3777s leveling agent (Efcona Chemicals) was added to the main agent, dispersed at 1000rpm for 30min, and then filtered out to obtain the ink product;

[0036] 3) Dilute the prepared high-temperature-resistant touch screen ink with a mixed diluent (mixed by isophorone and cyclohexanone at a mass ratio of 1:1) wi...

Embodiment 2

[0038] 1) Take 60g epoxy modified silicone resin HG-52 (Zhonghao Chenguang Chemical Research Institute Co., Ltd.), 10g Tiona-RCL69 titanium dioxide (Shanghai Jinghong Industry), 15g Tiona-595 titanium dioxide (Shanghai Jinghong Industry) , 5g glass powder, 2g nano-silica, 1g talc, 1g isophorone, 0.3g AFCONA5010 dispersant (Efcona Chemical), 0.3g AFCONA4010 dispersant (Efcona Chemical), 0.1g AFCONA3777s Add leveling agent (Efcona Chemicals) into the dispersion tank, stir evenly, grind and disperse for 90 minutes with a grinder at 2500rpm, and then filter to obtain the main agent;

[0039] 2) Take 2.25g CYMEL325 crosslinking agent (Weng Kaier Co., Ltd.), 2g DBE (diformate), 1g A-187 coupling agent, 1g KH550 coupling agent, 0.3g TEGO-628 dispersing agent (Dego Auxiliary), 0.1g AFCONA3670 leveling agent (Efcona Chemical), 0.05g GSK-716 defoamer (Gauss Fine Chemicals), added to the main agent, dispersed at 1200rpm for 30min, then filtered out to obtain ink products;

[0040]3) Di...

Embodiment 3

[0042] 1) Take 65g polyester modified silicone resin KE561 (Guangzhou Kanggujia Synthetic Materials Co., Ltd.), 30g Tiona-RCL69 titanium dioxide (Shanghai Jinghong Industry), 2g glass powder, 2g mica powder, 3g DBE (diformic acid Esters), 1g isophorone, 0.4g Silok7160 dispersant (Silok China Operation Center), 0.2g Silok-8144 leveling agent (Silok China Operation Center), add to the dispersion tank, stir well, Grind and disperse for 90 minutes at 2500rpm with a grinder, then filter to obtain the main agent;

[0043] 2) Take 3g CYMEL303 cross-linking agent (Weng Kaier Co., Ltd.), 1g cyclohexanone, 0.5g Z-6121 coupling agent (Dow Corning), 1g A187 coupling agent, 0.4g TEGO628 dispersant (Digo auxiliary) , 0.1g Silok-8244 leveling agent (Silok China Operation Center), 0.05g AFCONA2022 defoamer (Efcona Chemicals), add to the main agent, disperse at 1500rpm for 30min, filter and discharge to get the ink product ;

[0044] 3) Add the prepared high-temperature-resistant touch scree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com