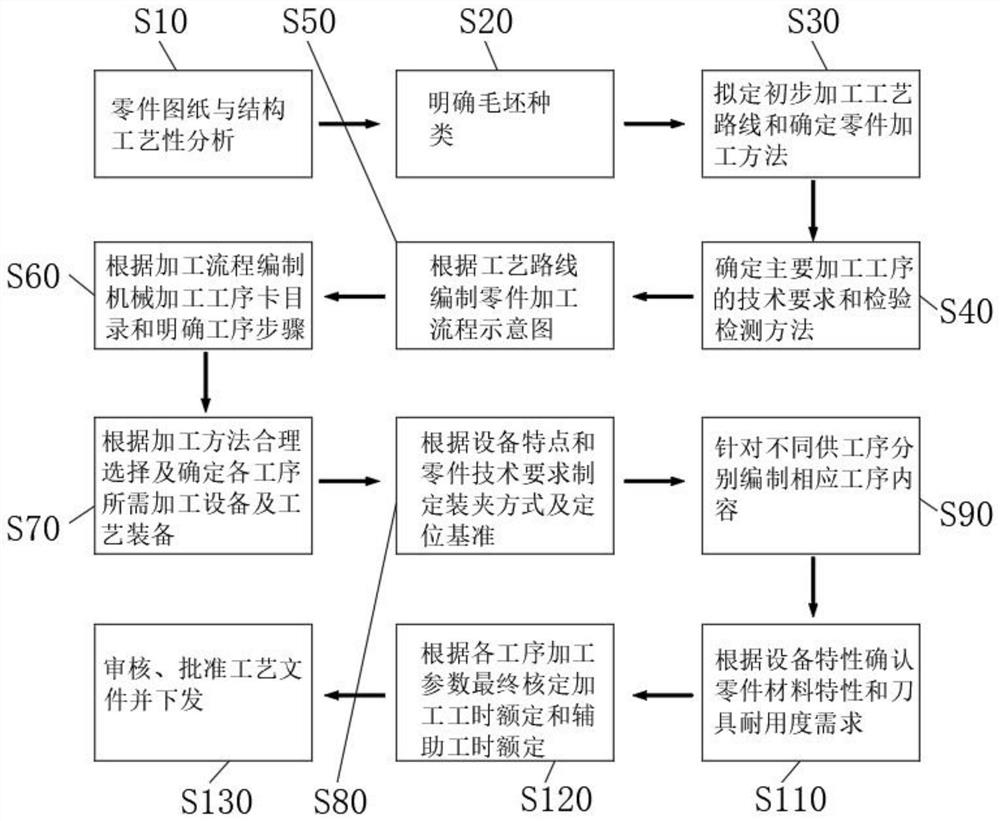

Machining process compilation method for parts

A technology of mechanical processing and parts processing, which is applied in the field of equipment related to the compilation of mechanical processing technology, and can solve problems such as incomplete expression of content, chaotic mechanical processing technology, and inability to reflect the complete process steps of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

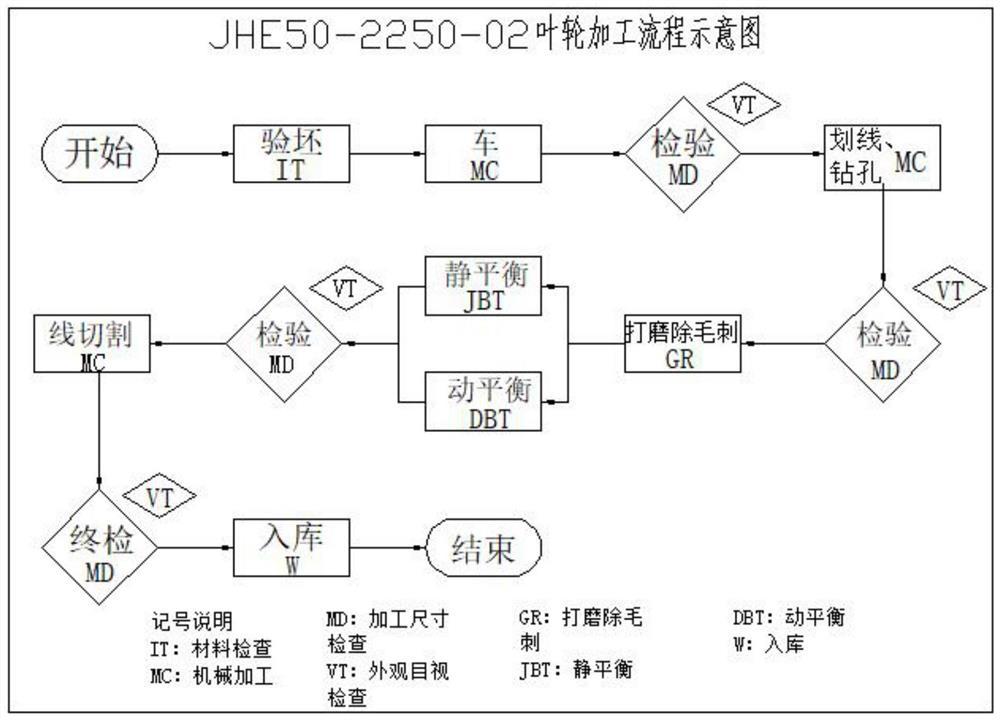

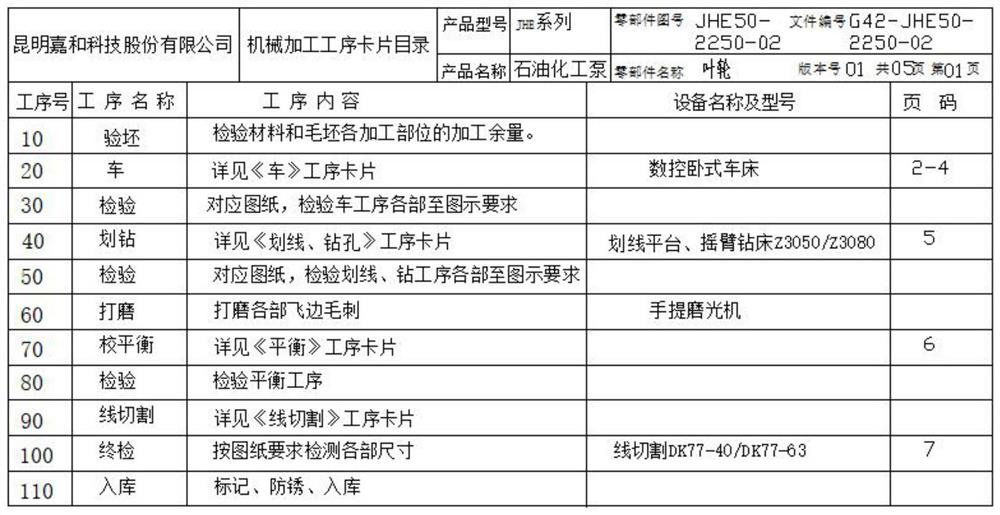

[0042] When specifically using the machining process preparation method of the parts provided by the invention:

[0043] 1. Analyze the part drawings and structural processability of the impeller JHE50-2250-02, and clarify the technical requirements of the drawings include: the maximum outer diameter Ф259 and the total width 95, the processing parts are all outer contours, 4 Ф9 holes and Ф32 inner holes and keyways ; The maximum beating is 0.04, the roughness of the mating parts is 3.2, and the rest parts are 12.5. The structure of the processing part can be realized through technological analysis.

[0044] 2. After measuring and confirming the blank of the part, the blank type, material (hardness), margin, shape, size and precision are clarified; the blank of the impeller JHE50-2250-02 is a casting, the precision is low, the material is 316, and the blank is just a round shape Outline, no center hole, large margin, 15mm on one side.

[0045] 3. After confirming the blank ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com