Cement printing automatic production system

An automatic production and cement technology, applied in the field of 3D printing, can solve the problems of increased integration and industrialization requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

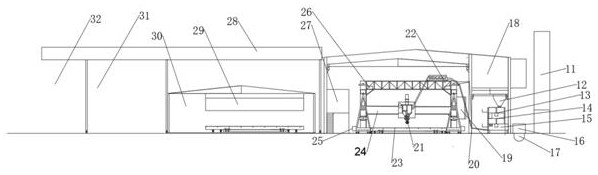

[0030] This embodiment provides a cement printing automatic production system, such as figure 1 shown, including:

[0031] A plurality of printing areas, each printing area corresponds to a feeding area, and the feeding area feeds materials to the printing area through the feed pipe 20; the printing area includes a printer, a mobile vehicle 23 and a transport track, and the transport track connects the printing area and the steam oxygen In zone 30, the mobile vehicle 23 is set on the transport track, and the printer prints cement products to the mobile vehicle 23 at the starting point of the transport track; the oxygen evaporation zone 30 is provided with product transport equipment connected to the product storage area. Due to the characteristics of cement, if you want to print on a large scale, the printing and mixing process has high requirements on temperature and humidity. Under normal circumstances, especially in winter, the temperature is low, and the printing process w...

Embodiment 2

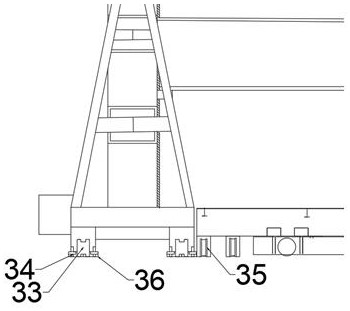

[0039] The cement printing automatic production system provided in this embodiment has the function of steel bar hoisting, and its steel bar hoisting part is as follows: image 3 As shown, the first support column is provided with a base, and the bottom of the base is provided with 23 wheelsets of mobile vehicles; each base is provided with a hoisting reinforcement inner column 2, and the top of the hoisting reinforcement inner column 2 is vertically connected to the 231 rails of the suspension reinforcement mobile vehicle, and The steel bar mobile car 231 track is arranged on the top of the beam 4 and is perpendicular to the cross beam 4; the steel bar inner column 2 is movably connected with a steel bar placement plate 3; the hanging steel bar mobile car 231 track is provided with a movable hanging steel bar mobile car 231; The mobile car 231 is connected with the steel bar placement plate 3 through a block of pulleys.

[0040] During the printing process, after printing a c...

Embodiment 3

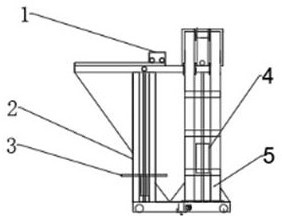

[0042] This embodiment provides an automatic production system for cement printing, and its feeding area includes a cement material bin 11, a mobile dry bin 12, a mixer 13, a mixing and storage bin 14, a pump 15, water and a water reducer Silo 16, water tank 17, mixer room 18 and feeding pipe 20; cement material warehouse is used to store cement materials; mobile dry material warehouse 12 is used to pour cement materials into mixer 13; water tank 17 and water and superplasticizer warehouse 16 Connected; the water and water reducer bin 16 is connected with the mixer 13; the outlet of the mixer 13 is connected with the stirring and storage bin; the mixing and storage bin is equipped with a pumping machine 15, and the pumping machine 15 is connected to the printer nozzle through the feeding pipe 20 21 is connected; the beam 4 is provided with a pulley block for lifting the feeding pipe 20. First pour the dry material into the mobile dry material bin 12, and control it to move abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com