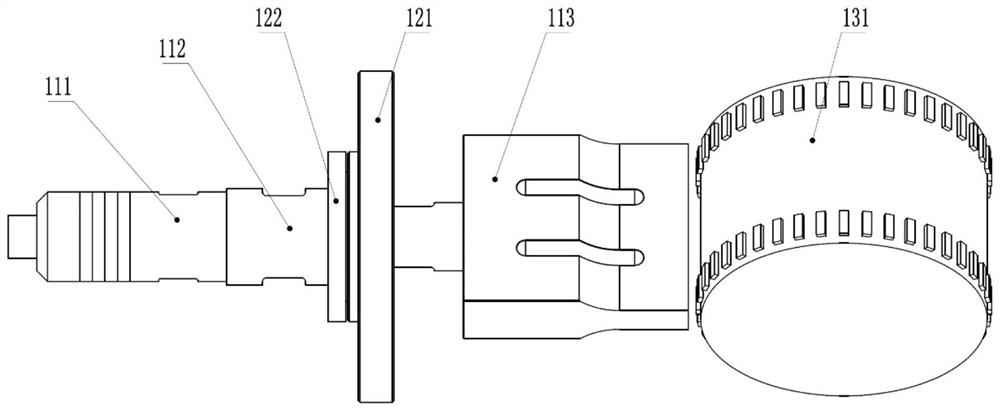

Longitudinal-radial coupled vibration integrated ultrasonic roll welding tool head

A coupled vibration, integrated technology, applied in the field of integrated ultrasonic roll welding tool head, can solve the problems of poor welding sealing, wrinkling of multi-layer non-woven products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

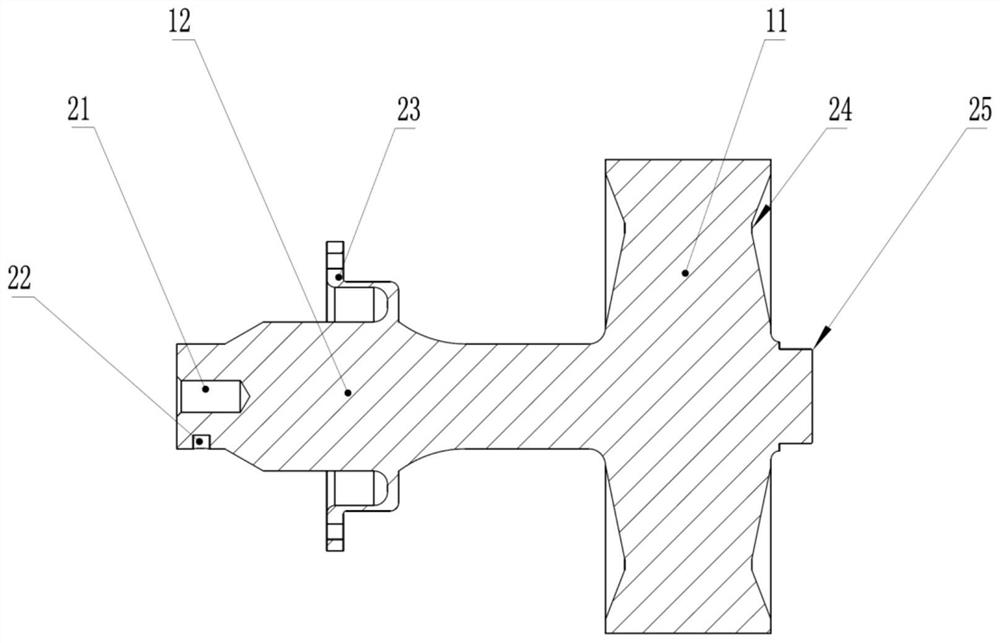

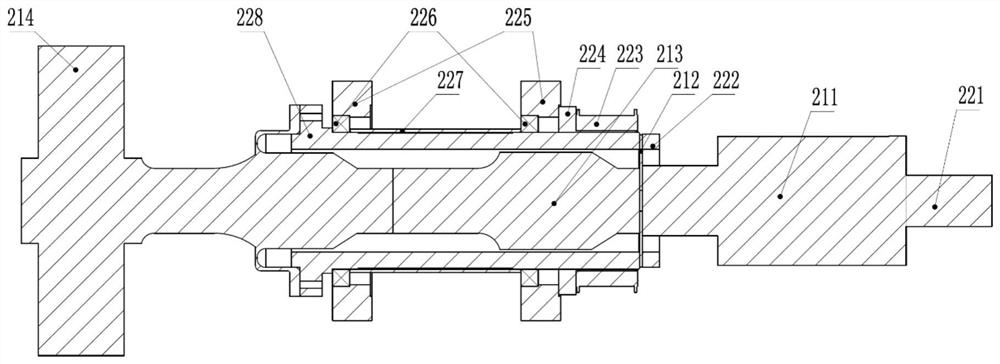

[0028] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0029] refer to figure 2 , the one-piece ultrasonic roll welding tool head with longitudinal-diameter coupling vibration provided by the present invention includes an integrally processed end disc structure 11 and an axial horn structure 12, and the overall axial section is T-shaped; The end of the horn structure 12 is provided with a counterbore 21 with an internal thread or a stud with an external thread for connection and installation with an external ultrasonic structure. On the outside of the end (counterbore 21) of the axial horn structure 12, a wrench hole 22 is provided for installation and use when connecting with an external ultrasonic structure. In the middle of the axial horn structure 12, flanges 23 are provided on the radial surface at the joints for fixed connection with the external ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com