Infrared light reflection heat insulation COC plastic and preparation method and application thereof

A technology of infrared reflection and infrared light, which is applied in the field of COC plastics, can solve the problems that there are no infrared heat-insulating COC plastics, cannot be realized, and cannot prevent degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The operating methods not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

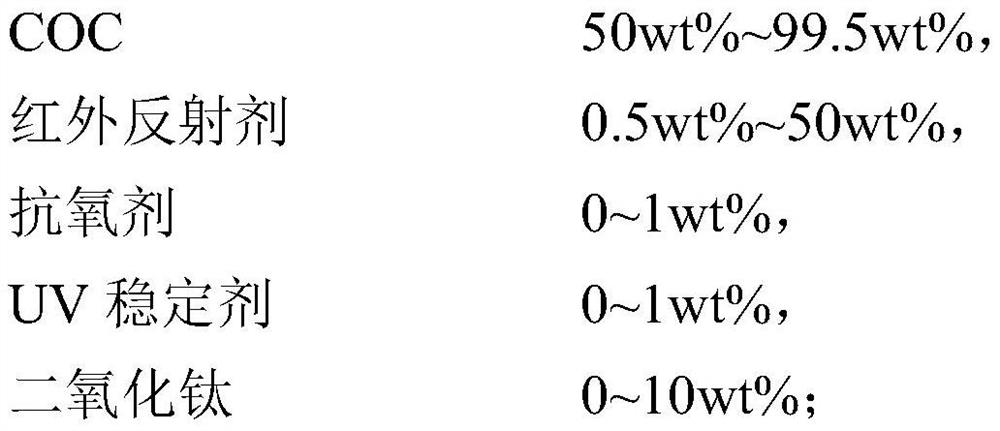

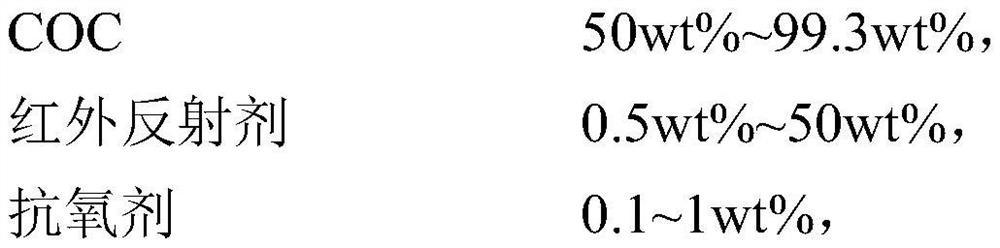

[0036] Tables 1 to 3 show the formulations of COC plastics of specific examples and comparative examples and the corresponding performance test results. Unless otherwise specified, the percentages of each raw material component are percentages by weight.

[0037] The preparation method of the COC plastics of each embodiment and comparative example: Measure each raw material component according to the formula shown in Tables 1 to 3, wherein COC adopts Topas 8007, and before use, dry it in vacuum at 100 ° C for 4 hours to remove moisture, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com