Production method of fructus cannabis meal protein polypeptide liquid, polypeptide liquid with uric acid reducing effect and application of polypeptide liquid

A technology of hemp seed meal and production method, which is applied in the field of polypeptide preparation with uric acid-lowering function, and can solve the problems of waste of resources and insufficient deep processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Mix the hemp seed meal and water according to the material-to-liquid ratio of 1:10, pass through a colloid mill to crush and mix evenly, and obtain the hemp seed meal stock solution; prepare the above stock solution to a suitable pH value of 7.5, put it into an ultrasonic cleaning machine, Power 400w, treat for 20 minutes; after inactivating the enzyme, add 12000U / g ([E] / [S]) alkaline protease to the protein stock solution, mix well, enzymolyze at 50°C for 5 hours, inactivate the enzyme, and obtain a one-step enzyme Polypeptide solution; 4000r / min centrifugal 10min can get HSPS1 (referring to the Hemp Seed Polypeptide Solution processed in Example 1).

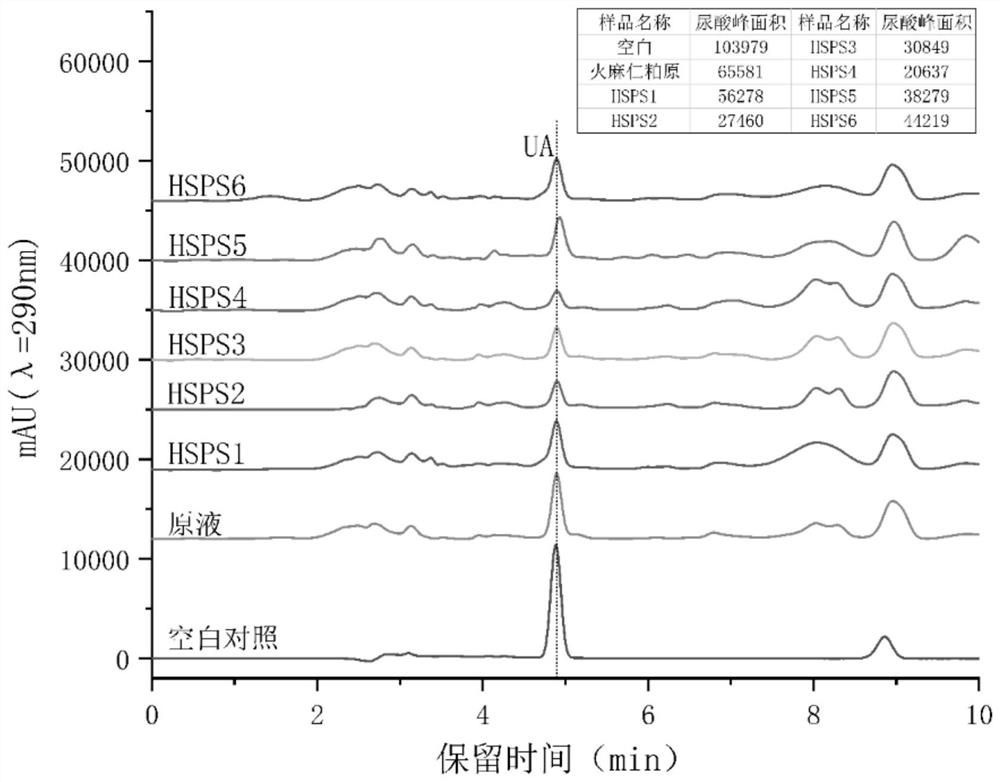

[0074] The peak shape and peak area of HSPS1 uric acid determined by RP-HPLC are as follows figure 1 .

Embodiment 2

[0076] Mix the hemp seed meal and water according to the material-to-liquid ratio of 1:10, pass through a colloid mill to crush and mix evenly, and obtain the hemp seed meal stock solution; prepare the above stock solution to a suitable pH value of 7.5, put it into an ultrasonic cleaning machine, Power 400w, treat for 20 minutes; after inactivating the enzyme, add 12000U / g ([E] / [S]) alkaline protease to the protein stock solution, mix well, enzymolyze at 50°C for 5 hours, inactivate the enzyme, and obtain a one-step enzyme Polypeptide hydrolysis liquid; pasteurize the one-step enzymatic hydrolysis polypeptide liquid, insert 2% Lactobacillus bulgaricus, anaerobically ferment at 43°C for 8h, and ferment at 4°C for 24h; sterilize, centrifuge at 4000r / min for 10min to obtain HSPS2 (refer to What is treated in embodiment 2 is the hemp seed polypeptide liquid that obtains).

[0077] The peak shape and peak area of HSPS2 uric acid determined by RP-HPLC are as follows figure 1 .

Embodiment 3

[0079] Mix the hemp seed meal and water according to the material-to-liquid ratio of 1:10, pass through a colloid mill to crush and mix evenly, and obtain the hemp seed meal stock solution; prepare the above stock solution to a suitable pH value of 7.5, put it into an ultrasonic cleaning machine, Power 400w, treat for 20 minutes; after inactivating the enzyme, add 12000U / g ([E] / [S]) alkaline protease to the protein stock solution, mix well, enzymolyze at 50°C for 5 hours, inactivate the enzyme, and obtain a one-step enzyme Polypeptide hydrolysis solution; pasteurize the one-step enzymatic hydrolysis polypeptide solution and insert 2% Lactobacillus delbrueckii, anaerobically ferment at 43°C for 8h, and ferment at 4°C for 24h; sterilize, centrifuge at 4000r / min for 10min to obtain HSPS3( Refer to the hemp seed polypeptide liquid obtained by processing in embodiment 3).

[0080] The peak shape and peak area of HSPS3 uric acid determined by RP-HPLC are as follows figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com