Membrane electrode activation method for SPE electrolytic cell, application and electrolytic cell structure

An activation method and electrolytic cell technology, applied in the field of membrane electrode activation method for SPE electrolytic cells and its SPE electrolytic cell structure, can solve problems such as insufficient research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

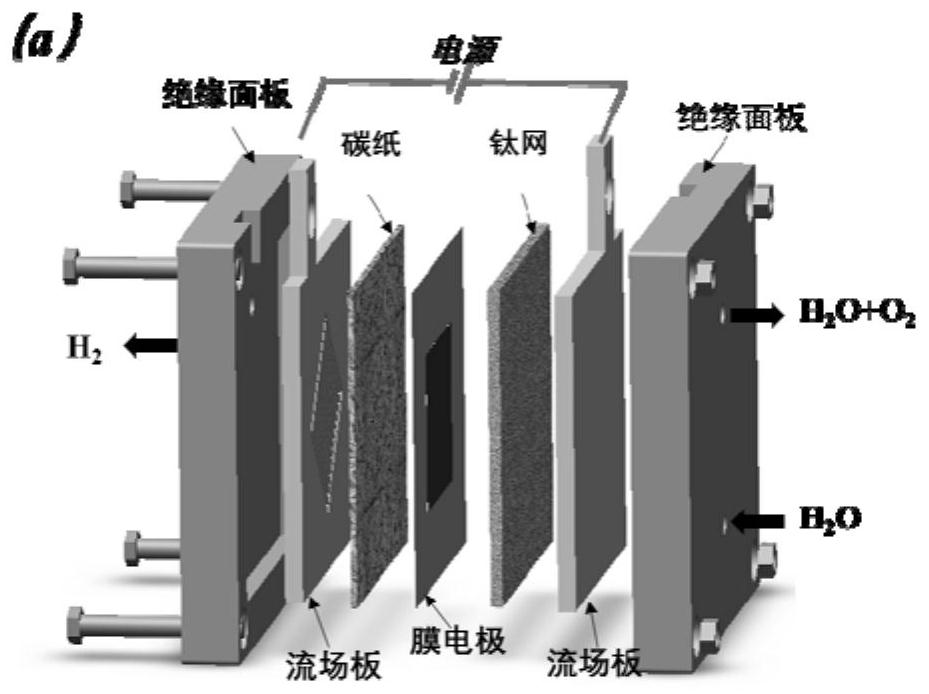

[0038] As shown in Figure 1, a kind of SPE electrolyzer structure that the present invention provides, comprises insulation panel, flow field plate, titanium net, membrane electrode, carbon paper and externally connected load power supply, water supply device and voltage, current reading meter, Among them: two insulating panels are arranged oppositely, two flow field plates are arranged relatively between the two insulating panels, titanium mesh and carbon paper are arranged relatively between the two flow field plates, and membrane electrodes are arranged on the Between the titanium mesh and the carbon paper; the connected load power supply provides activation current for the SPE electrolyzer; the connected water supply device feeds deionized water with controllable temperature and flow rate into the anode side of the SPE electrolyzer; the connected voltage and current The reading meter is used to read the value of the load voltage and current of the SPE electrolyzer.

[0039...

Embodiment 2

[0044] The deionized water is passed into the anode side of the SPE electrolytic cell. Before the load current or voltage is applied, the SPE membrane needs to be pre-wetted. The temperature of the deionized water is 80°C, the flow rate is 20ml / min, and the pre-wet time is 2h, the full wetting of the SPE membrane was obtained.

[0045] Subsequently, an initial current density was applied to the SPE electrolyzer set to 0A cm -2 , the load current density increased to 3A cm through 10 stages -2, each stage maintains constant current operation for 20 minutes, and then passes through 10 stages from 3A cm -2 Decrease to 0Acm -2 , the number of stages of decreasing current density is the same as the number of stages of increasing current density, the value of increasing or decreasing current density is the same, and the running time is the same; in addition, at the same time, the anode side is continuously fed with deionized water with a water temperature of 80 °C and a flow rate ...

Embodiment 3

[0047] Deionized water is introduced into the anode side of the SPE electrolytic cell. Before applying the load current or voltage, the SPE membrane needs to be pre-wetted. The temperature of the deionized water is 70°C, the flow rate is 10ml / min, and the pre-wet time is 3h, the full wetting of the SPE membrane was obtained.

[0048] Then apply a load constant voltage of 2V to the SPE electrolyzer, and at the same time continue to feed deionized water with a water temperature of 70°C and a flow rate of 30ml / min on the anode side. After 12 hours, the current of the SPE electrolyzer maintains a change of ±0.002A, indicating that the activation is complete. Figure 4 Cyclic voltammetry schematics show a large increase in active sites after activation compared to unactivated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com