Wheat straw mud wall surface technology suitable for concrete structure koji house

A technology of concrete structure and wheat straw, which is applied in the direction of building structure, construction, covering/lining, etc., and can solve the problems of falling off, poor bonding ability, partial falling off of the whole wheat straw mud wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

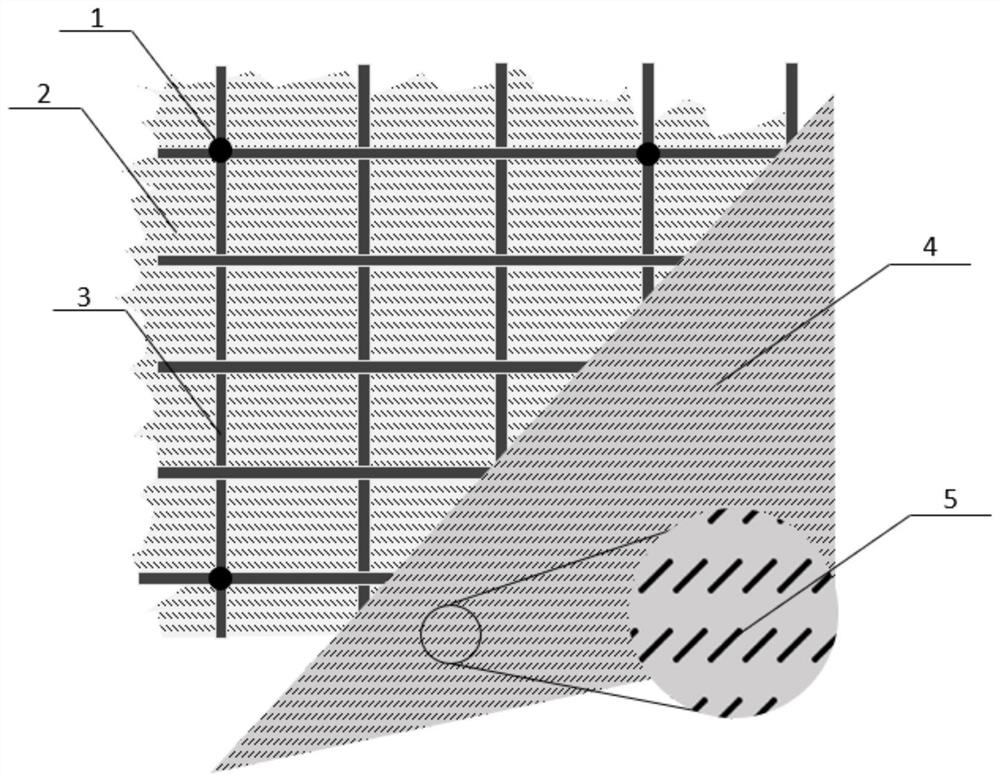

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a wheat straw mud wall surface process suitable for a curved room with a concrete structure, including the following process steps:

[0034] Step 1; Material preparation

[0035] Prepare an appropriate amount of yellow clay, store it flat, and store it under natural conditions for 2 days. The moisture content reaches the level of "holding tightly and forming a ball, and it will bloom on the ground". Take 0.5 kg of dipotassium hydrogen phosphate and sodium nitrate mixed in a ratio of 1:1, and fully dissolve in water for later use;

[0036] Step 2: Mix the mud

[0037] Three days before the mud wall surface, add water to the fine, sand-free, viscous, pollution-free and bacteria-free yellow glue mud for mixing. During the mixing process, add 200 kg of wheat straw and Add 6 kilograms of koji powder, and add the solution of dipotassium hydrogen phosphate and sodium nitrate, stop after fully stirri...

Embodiment 2

[0047] Such as figure 1 As shown, the embodiment of the present invention provides a wheat straw mud wall surface process suitable for a curved room with a concrete structure, including the following process steps:

[0048] Step 1; Material preparation

[0049] Prepare an appropriate amount of yellow clay, store it flat, and store it under natural conditions for 3 days. The moisture content reaches the level of "hold tightly and form a ball, and it will bloom on the ground". Take 0.5 kg of dipotassium hydrogen phosphate and sodium nitrate mixed in a ratio of 2:1, and fully dissolve in water for later use;

[0050] Step 2: Mix the mud

[0051] Four days before the mud wall surface, add water to the yellow glue mud with fine soil, no sand, sticky, no pollution and no bacteria, and mix it. During the mixing process, add 200 kg of wheat straw and Add 6 kilograms of koji powder, and add the solution of dipotassium hydrogen phosphate and sodium nitrate, stop after fully stirring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com