An automatic processing device suitable for oil drilling strings and its working method

A processing device and oil drilling technology, which is applied to drill pipes, drilling equipment, casings, etc., can solve the problems of time-consuming and labor-intensive column establishment and storage, and achieve the effects of reduced labor intensity, simple structure, and simplified transportation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to clearly describe the technical characteristics of the present plan, the present invention will be described in detail in connection with the accompanying drawings.

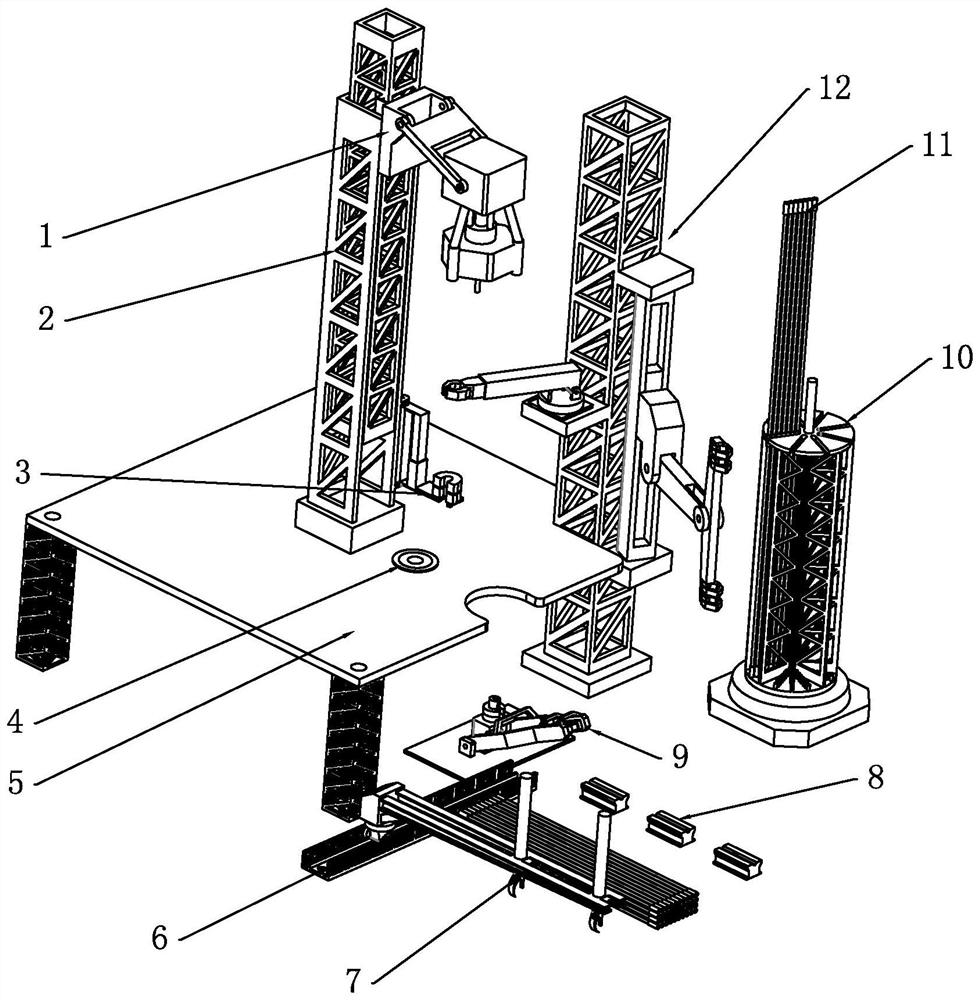

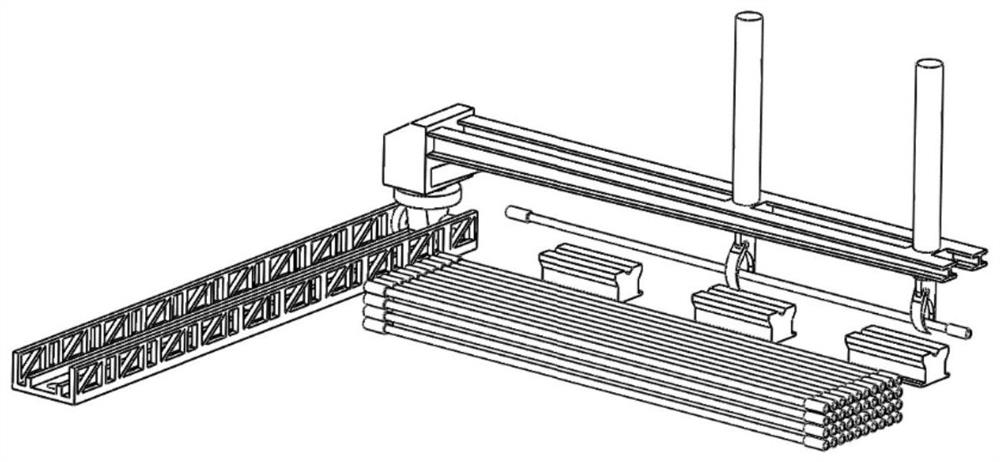

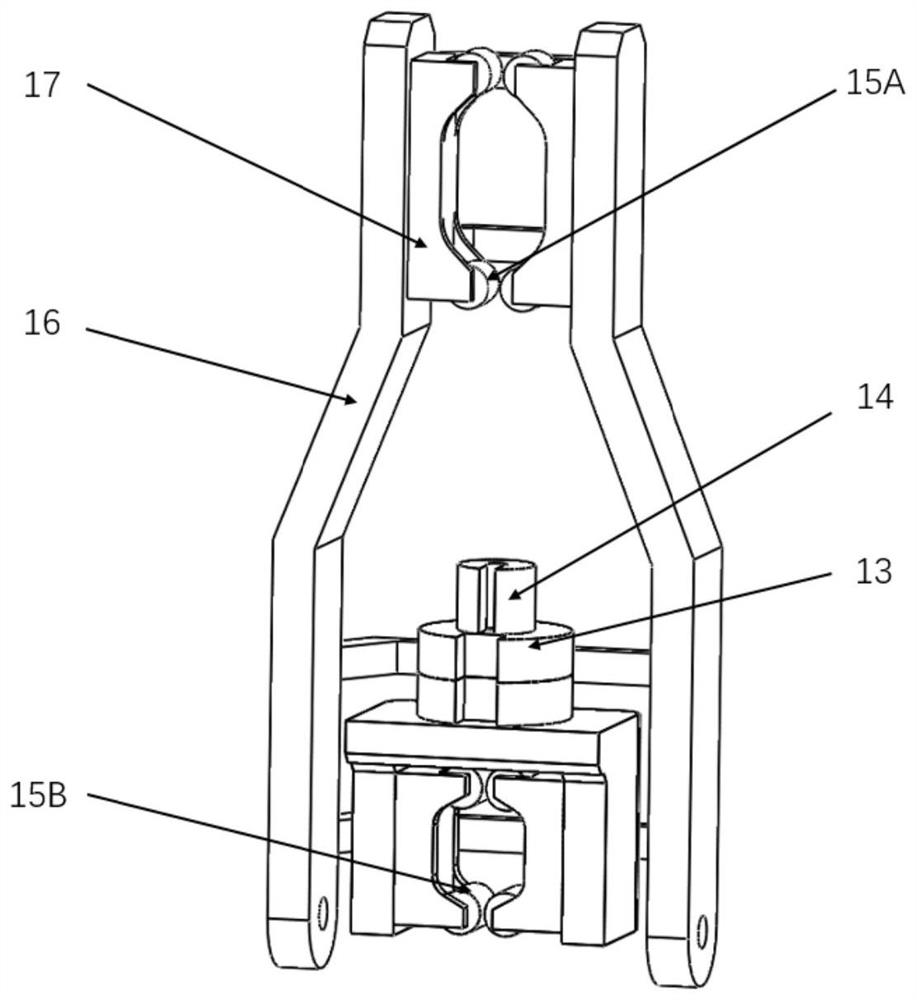

[0055] like Figure 1-8 As shown, the oil drilling pillar automation processing device includes a ground tube automated conveying unit that cooperates, a tube automated transport unit, a drill stand automation processing unit, and a column storage unit, and the unit formula to achieve a drilling tube. The drilling operation of the column is automated.

[0056] The above ground tube automation conveying unit includes a valley robot arm 7, a rail 6, and a column positioning guide rail 8, and the gripping robot arm slides on the slide and places a single tube column and placed onto the tube position guide 8. The valley mechanical arm 7 is slid horizontally on the guide rail 6 by hydraulic drive and electrical drive form, in order to achieve a grab delivery operation of a single tube column on the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com