Semiconductor power device test heating table

A technology of power devices and semiconductors, which is applied in the field of semiconductor power device test heating tables, and can solve problems such as different heating speeds, inconsistent environmental conditions of semiconductor power devices, and uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

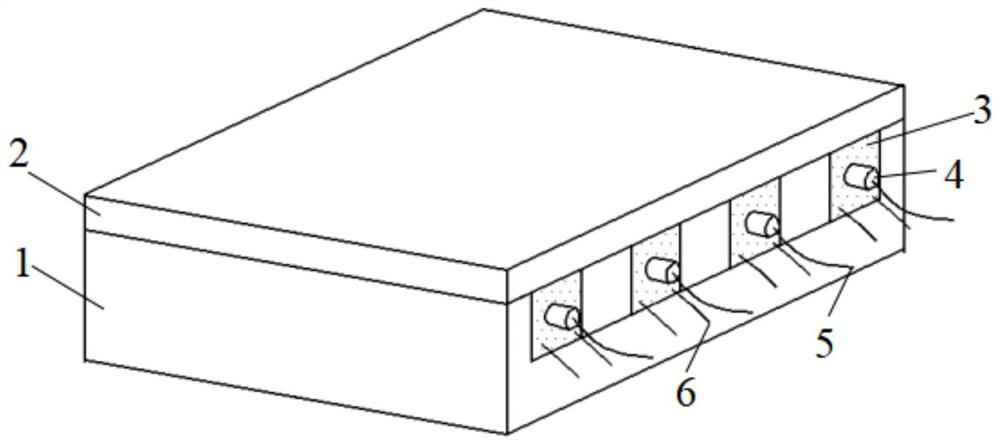

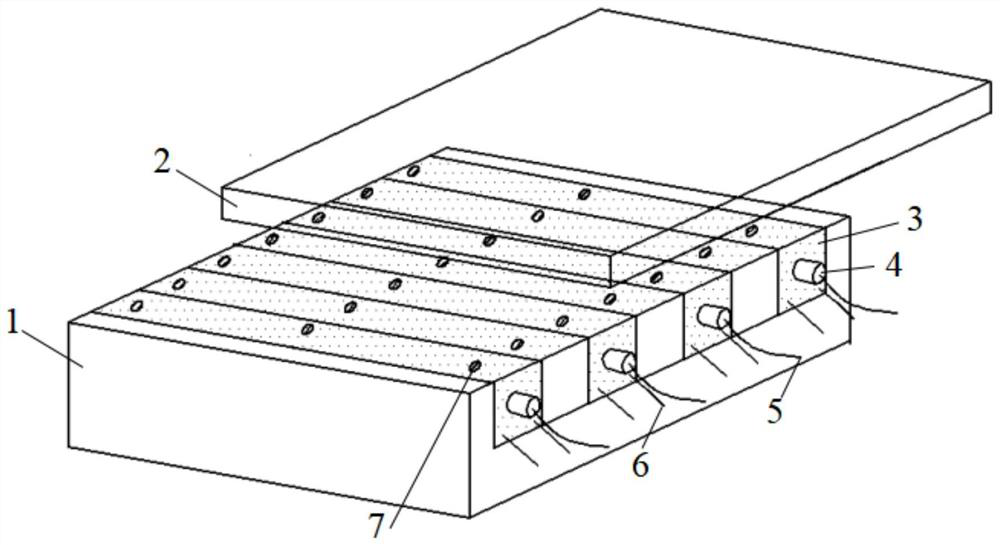

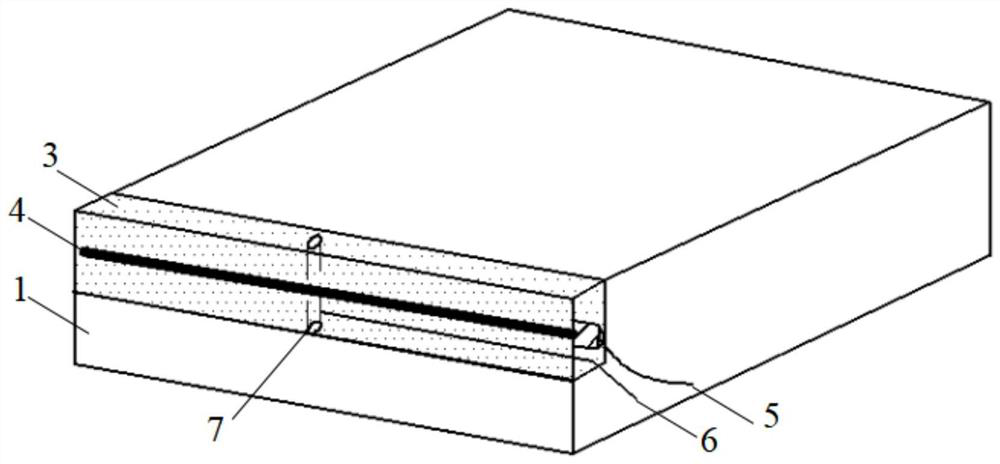

[0026] A test heating table for semiconductor power devices, used for heating during test and analysis of semiconductor devices, combined with the attached Figure 1-6 As shown, the structure of the heating platform includes: light metal layer 1; ceramic layer 2; filled with thermally conductive material 3; out). In this embodiment, the heating element 4 is an iron-chromium-aluminum heating wire, the temperature probe 7 is a Pt10 temperature probe, and the heat-conducting material 3 is filled with a heat-conducting resin.

[0027] The power controller provides the external voltage and current required by the heating table, and the voltage, current and temperature of each position of the heating table can be viewed on the controller display.

[0028] Among them, the heating platform adopts an upper and lower two-layer structure, and the upper ceramic layer 2 is a thin layer of ceramic Al 2 o 3 , with a thickness of 2mm, the lower light metal layer 1 is made of light metal al...

Embodiment 2

[0032] A test heating table for semiconductor power devices, used for heating during test and analysis of semiconductor devices, combined with the attached Figure 1-6 As shown, the structure of the heating platform includes: light metal layer 1; ceramic layer 2; filled with thermally conductive material 3; out). In this embodiment, the heating element 4 adopts nickel-chromium heating wire, the temperature probe 7 adopts a Pt100 temperature probe, and the filling heat-conducting material 3 adopts heat-conducting glue.

[0033] The power controller provides the external voltage and current required by the heating table, and the voltage, current and temperature of each position of the heating table can be viewed on the controller display.

[0034] Among them, the heating table adopts a two-layer structure, the upper ceramic layer 2 is a thin layer of ceramic AlN with a thickness of 4mm, and the lower light metal layer 1 is made of light metal stainless steel to reduce the weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com