Transfer printing process method for filling via hole with silver colloid

A process method and via hole technology, which is applied in the field of silver glue filling in the transfer printing process, can solve the problems of low conduction performance of the first-level appearance, influence of conduction performance, and unfavorable use, so as to improve innovation and conduction performance , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

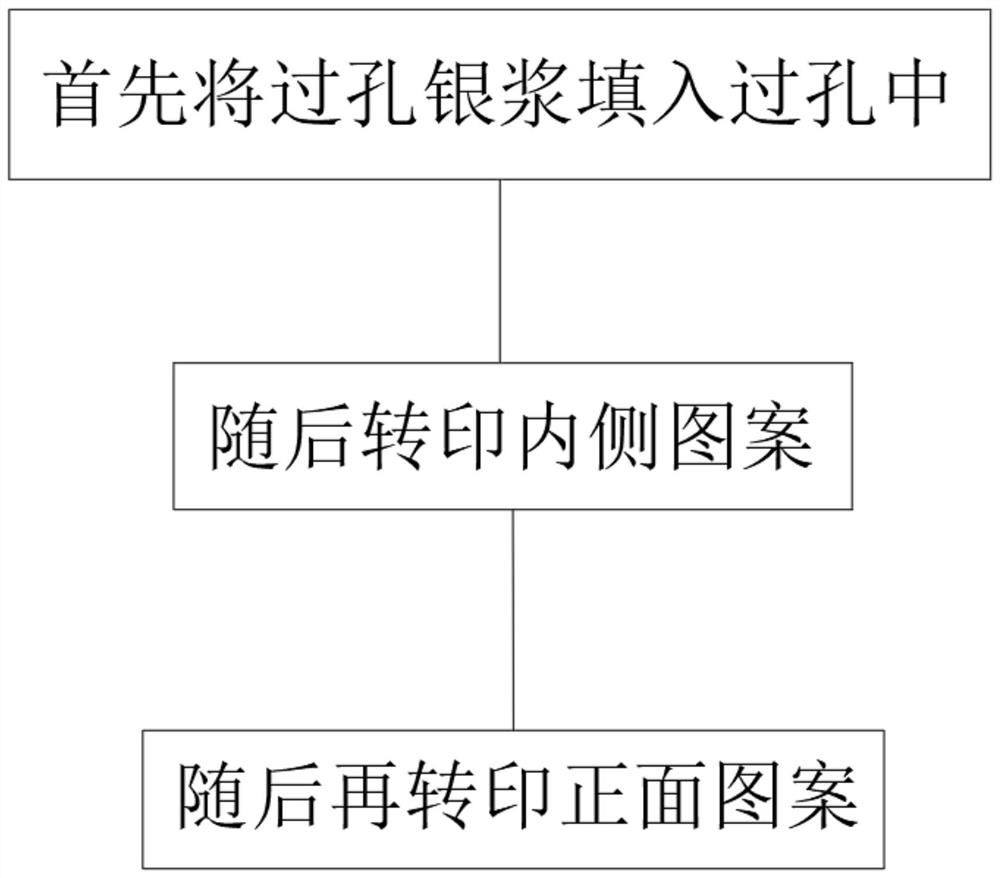

[0020] Embodiment one, refer to figure 1 , the transfer printing process method for filling via holes with silver glue comprises the following steps:

[0021] S1, first fill the via hole silver paste into the via hole;

[0022] S2, subsequently transferring the inner pattern;

[0023] S3, and then transfer the front pattern.

[0024] Preferably, in S1, the viscosity of the via-hole silver paste is 2500cp, and the via-hole silver paste is added with an amine curing agent or a cyanotype curing agent.

[0025] Preferably, in S2, the through-hole silver paste is filled into the via holes by an automatic glue dispenser, and the needle of the automatic glue dispenser is a dispensing needle with an inner diameter of 0.21 mm.

[0026] Preferably, in S2, the air pressure of the automatic glue dispenser is 0.35Mpa, and one glue-out operation and two press-down operations are adopted.

[0027] Preferably, after the dispensing of the automatic glue dispenser is completed, the product ...

Embodiment 2

[0029] Embodiment two, refer to figure 1 , the transfer printing process method for filling via holes with silver glue comprises the following steps:

[0030] S1, first fill the via hole silver paste into the via hole;

[0031] S2, subsequently transferring the inner pattern;

[0032] S3, and then transfer the front pattern.

[0033] Preferably, in S1, the viscosity of the via hole silver paste is 2550cp, and the via hole silver paste is added with an amine curing agent or a cyanotype curing agent.

[0034] Preferably, in S2, the via-hole silver paste is filled into the via holes by an automatic glue dispenser, and the needle of the automatic glue dispenser is a dispensing needle with an inner diameter of 0.36 mm.

[0035] Preferably, in S2, the air pressure of the automatic glue dispenser is 0.40Mpa, and one glue-out operation and two press-down operations are adopted.

[0036] Preferably, after the dispensing of the automatic glue dispenser is completed, the product is l...

Embodiment 3

[0038] Embodiment three, refer to figure 1 , the transfer printing process method for filling via holes with silver glue comprises the following steps:

[0039] S1, first fill the via hole silver paste into the via hole;

[0040] S2, subsequently transferring the inner pattern;

[0041] S3, and then transfer the front pattern.

[0042] Preferably, in S1, the viscosity of the via-hole silver paste is 2600cp, and the via-hole silver paste is added with an amine curing agent or a cyanotype curing agent.

[0043] Preferably, in S2, the through-hole silver paste is filled into the via holes by an automatic glue dispenser, and the needle of the automatic glue dispenser is a glue dispense needle with an inner diameter of 0.35 mm.

[0044] Preferably, in S2, the air pressure of the automatic glue dispenser is 0.42Mpa, and one glue-out operation and two press-down operations are adopted.

[0045] Preferably, after the dispensing of the automatic glue dispenser is completed, the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com