Copper-aluminum composite pole, cathode cover plate assembly structure and energy storage unit

A copper-aluminum composite and board assembly technology is applied in the field of electric energy storage, which can solve the problems of difficult control, affecting welding reliability, and difficult processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0036] The energy storage element of the present invention is a super capacitor, or a battery, or other energy storage structures.

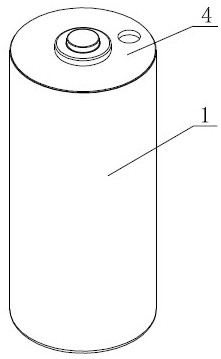

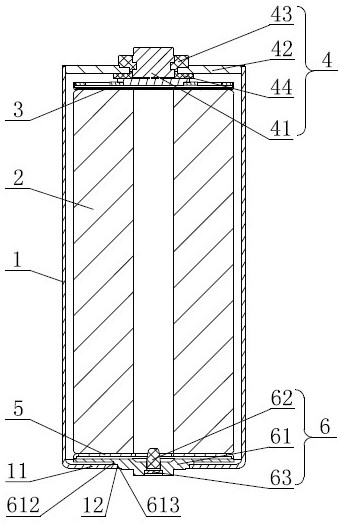

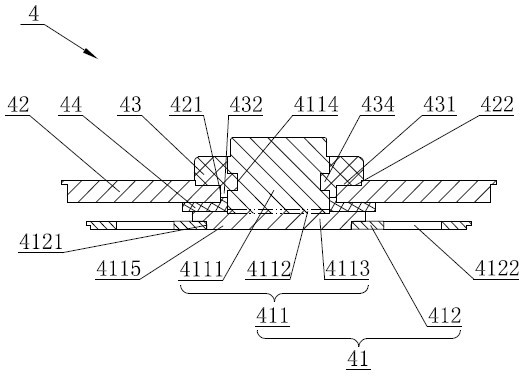

[0037] like figure 1 , figure 2 As shown, the casing 1 of the present invention is in the shape of a barrel with a fully open top and a bottom surface 11 at the bottom, and a first central hole 12 is opened in the center of the bottom surface 11 . A battery cell 2 is inserted into the casing 1. The top end of the battery cell 2 is fixedly connected to a negative electrode cover plate assembly 4 through a negative electrode current collector plate 3, and the bottom end of the battery core 2 is fixedly connected to a positive electrode cover plate assembly through a positive electrode current collector plate 5. 6. The negative electrode current collector disc 3 is made of copper material, and the positive electrode curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com