Intensive pouring bus duct assembly

A busway, intensive technology, applied in the field of busway, can solve the problems of large space occupied by busway, poor applicability, and low fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

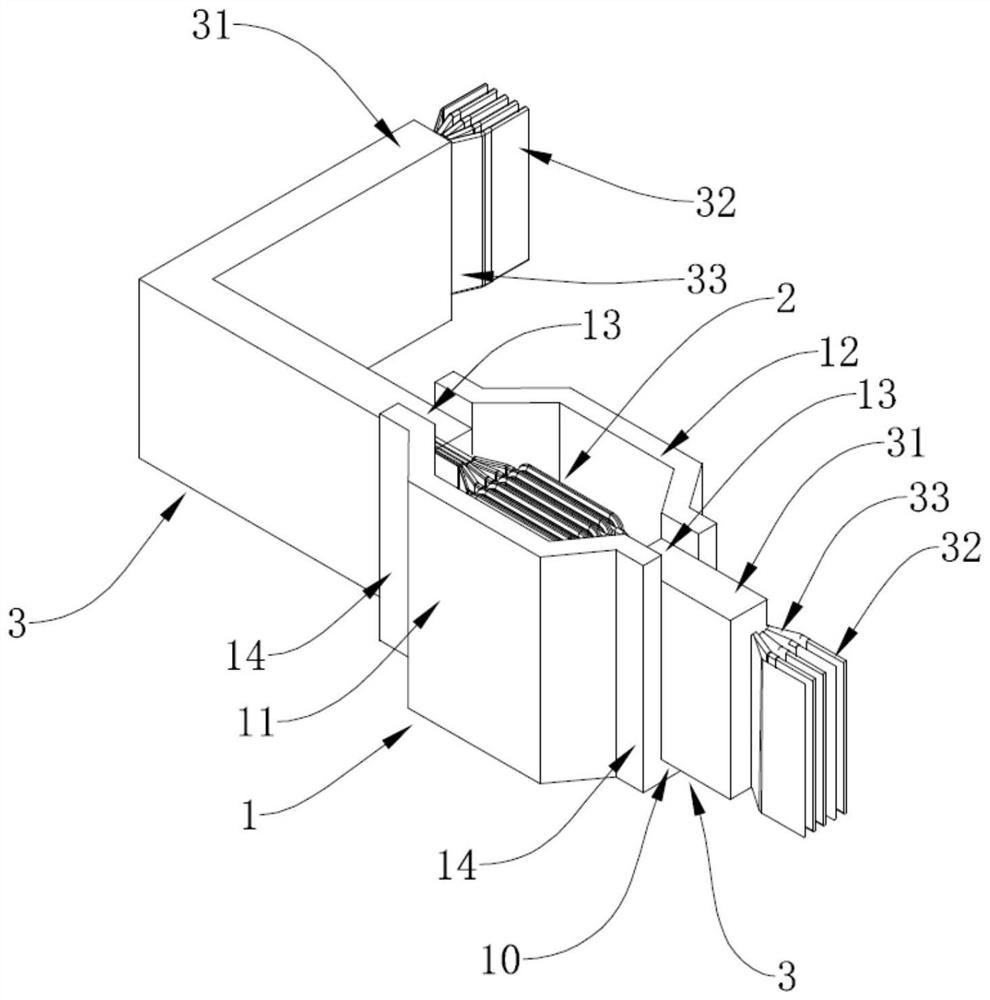

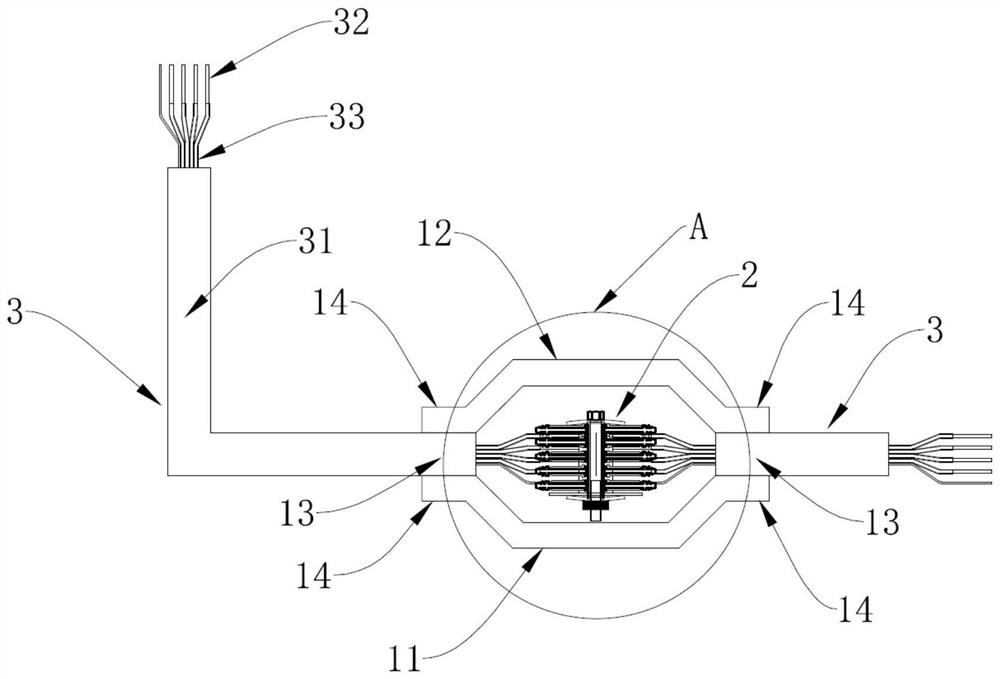

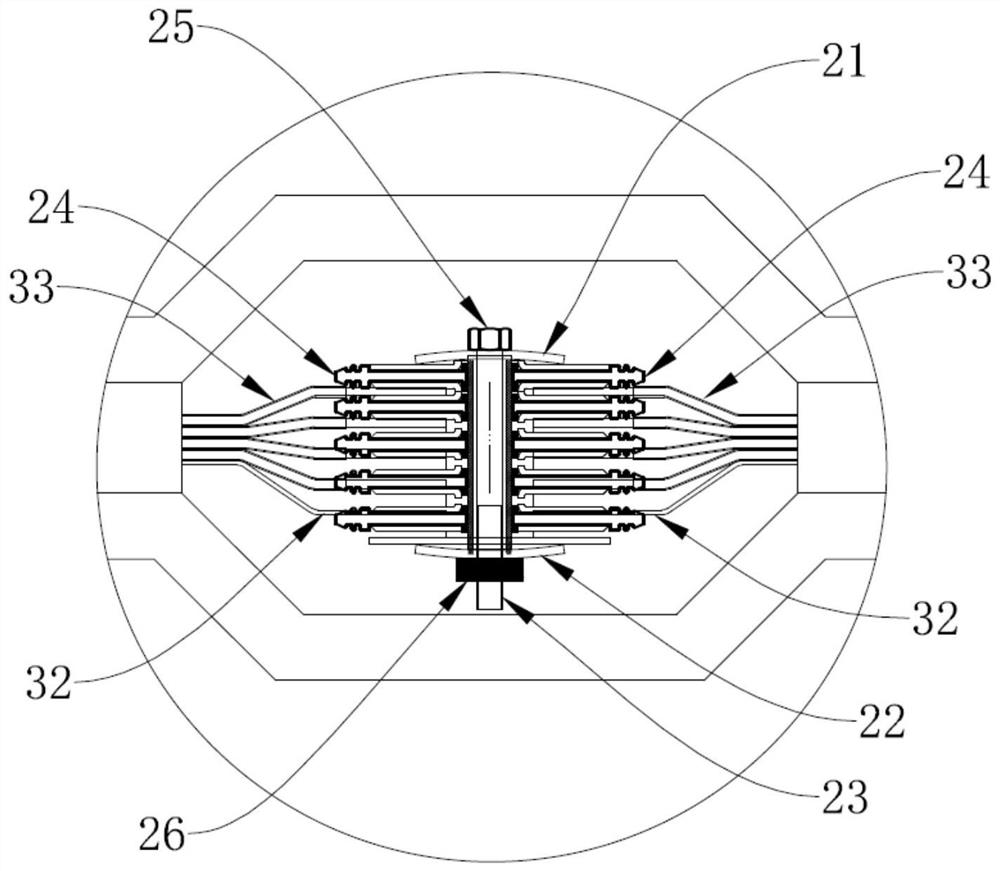

[0024] refer to figure 1 with figure 2 , Embodiment 1 provides a dense cast bus duct assembly, including a connecting outer box 1, a splicing unit 2 and several bus duct units 3, the bus duct unit 3 includes a housing 31 and several copper bars 32, the copper bars 32 The surface is provided with a film-coated insulating layer 33, and several copper bars 32 are stacked and penetrated in the inner cavity of the housing 31. Both ends of the copper bars 32 protrude from the inner cavity of the housing 31. The copper bars 32 are connected through the splicing unit 2, and the connecting outer box 1 is arranged outside the exposed connection part of the two copper bars 32, and the connecting outer box 1 encloses a storage space, and the refractory castable material is cast in the storage space.

[0025] It should be noted that each bus duct unit 3 can be set in different lengths and shapes in order to adapt to various installation environments. Section by section bus duct units 3 a...

Embodiment approach

[0028] As another embodiment, the refractory casting material includes the following components: 55-65 parts of novolac epoxy resin, 10-16 parts of curing agent, 20-25 parts of quartz sand, and 7-14 parts of vermiculite. Wherein: the configuration method of pouring material comprises the following steps: Step 1, putting the novolac epoxy resin, curing agent, quartz sand, and vermiculite of corresponding weight parts into the vacuum agitator; Step 2, setting the pressure of the vacuum agitator to 1.0MPa , and stirred for 15 minutes; step 3, obtaining a liquid casting material.

[0029] As another embodiment, the refractory castable material comprises proportions by weight: 50-100 parts of resin, 25-100 parts of flame retardant, 5-50 parts of thermally conductive filler, 25-100 parts of common filler and 5-20 parts of graphene. Among them, graphene is added with graphene oxide; the resin is one of unsaturated resin, polyurethane resin, epoxy resin, and silicone resin; the flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com