Uniform light type photovoltaic agricultural system

A uniform light, photovoltaic technology, applied in agriculture, photovoltaic power generation, photovoltaic modules, etc., can solve problems such as failure to grow well and affect the power generation of solar photovoltaic panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

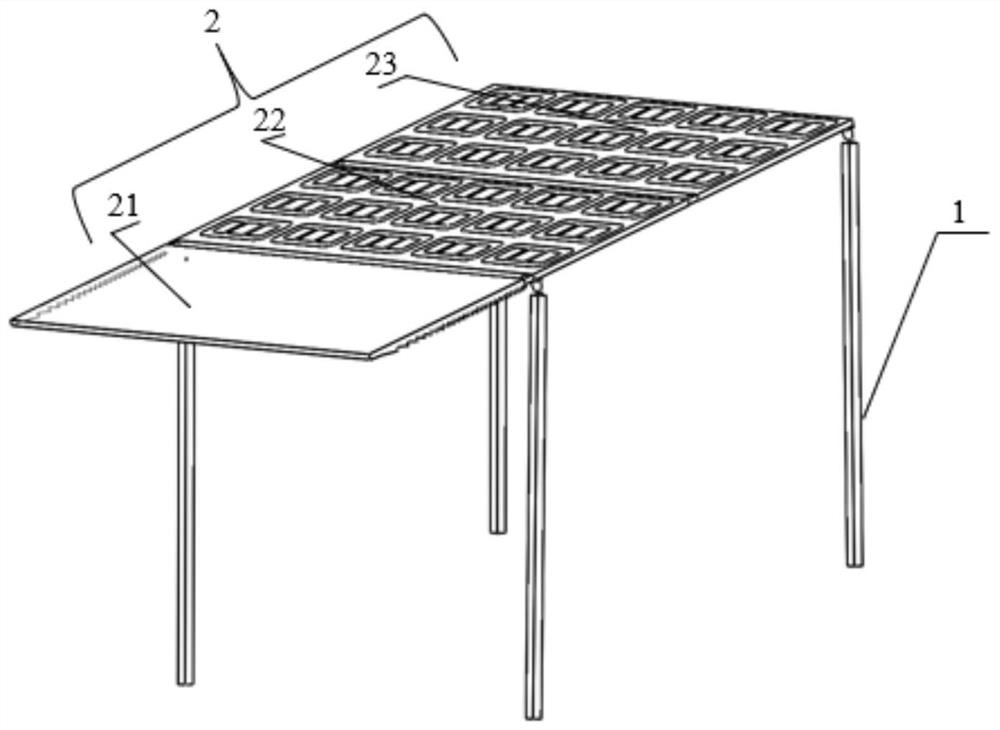

[0032] Such as figure 1 A uniform light photovoltaic agricultural system is shown, which includes a support 1 and a solar photovoltaic panel assembly 2 on the support 1. The solar photovoltaic panel assembly 2 includes a first solar photovoltaic panel 21, a second solar photovoltaic panel 22 and a pressure groove light splitter. The glass plate 23, the grooved light-splitting glass plate 23 realizes the splitting effect on sunlight, the grooved light-splitting glass plate 23 is on the lower side of the second solar photovoltaic panel 22, the first solar photovoltaic panel 21, the second solar photovoltaic panel 22 and The width of the grooved light-splitting glass plate 23 is 1.07m, and there is a 5mm gap between the second solar photovoltaic panel 22 , the first solar photovoltaic plate 21 and the grooved light-splitting glass plate 23 .

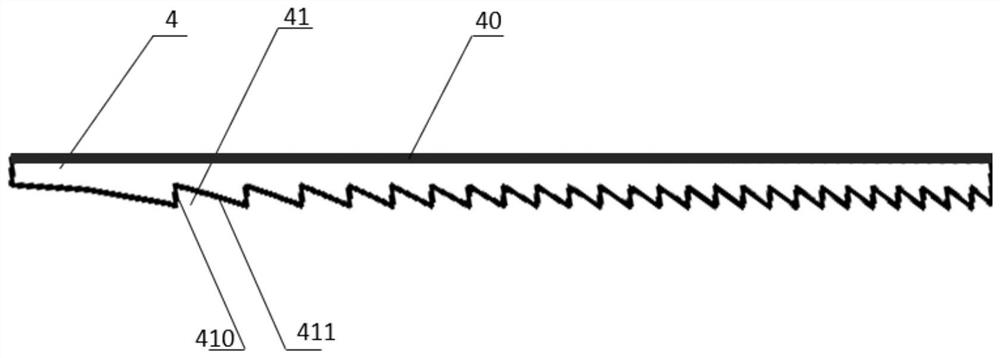

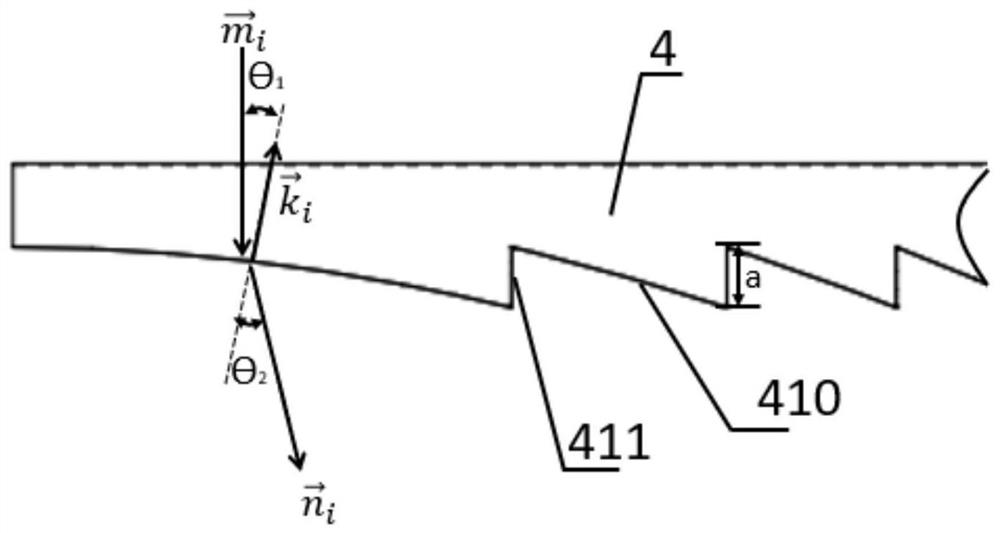

[0033] Such as figure 2 As shown, the grooved light-splitting glass plate 23 is made of high transmittance glass 4 , the upper surface 4...

Embodiment 2

[0042] Such as Figure 7 As shown, the difference between the second embodiment and the first embodiment is that: the upper side of the solar photovoltaic panel 21 is also equipped with a grooved light-splitting glass plate 23, and its lower surface is also formed by an array of grooves. The advantage of this installation method is that the uniform irradiation of sunlight 5 on the agricultural land 6 can be realized when the installation height of the solar photovoltaic panel assembly 2 is relatively low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com