Valve tower temperature monitoring system and method

A monitoring system and valve tower technology, used in thermometers, thermometer applications, thermometer components, etc., can solve problems such as inability to detect equipment abnormalities in time, unreliable equipment detection, and increase the work intensity of staff to reduce maintenance. Strength and maintenance cost, improve maintenance efficiency, and detect reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] System embodiment:

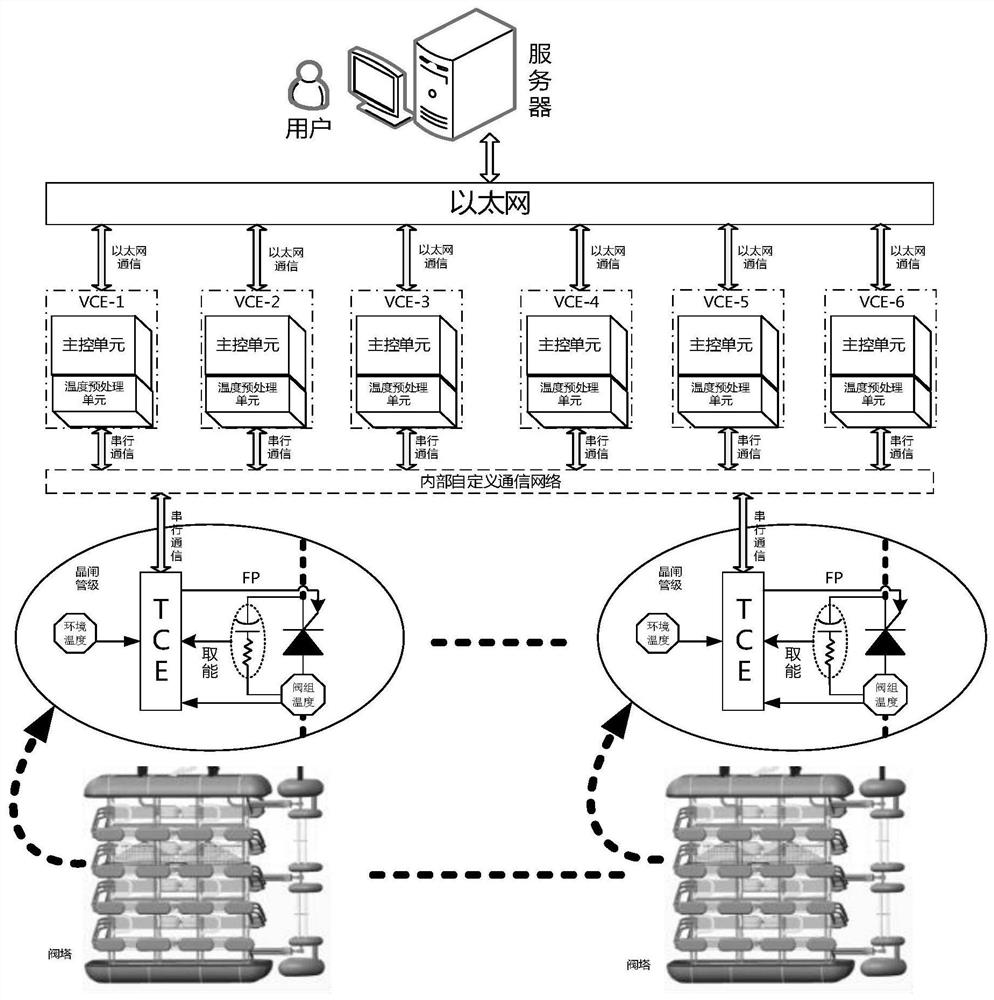

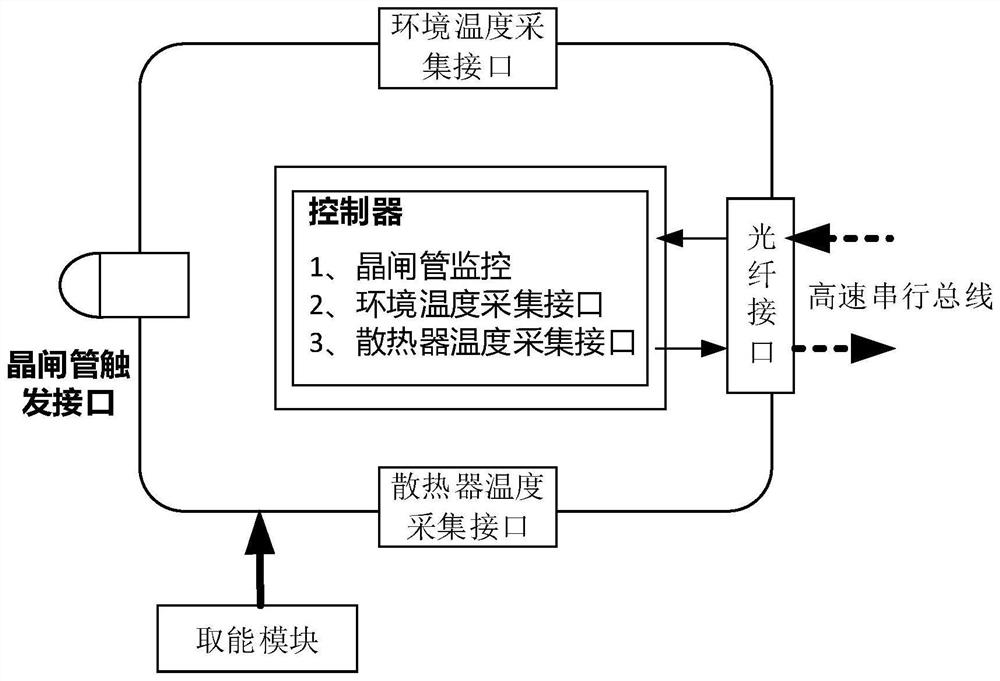

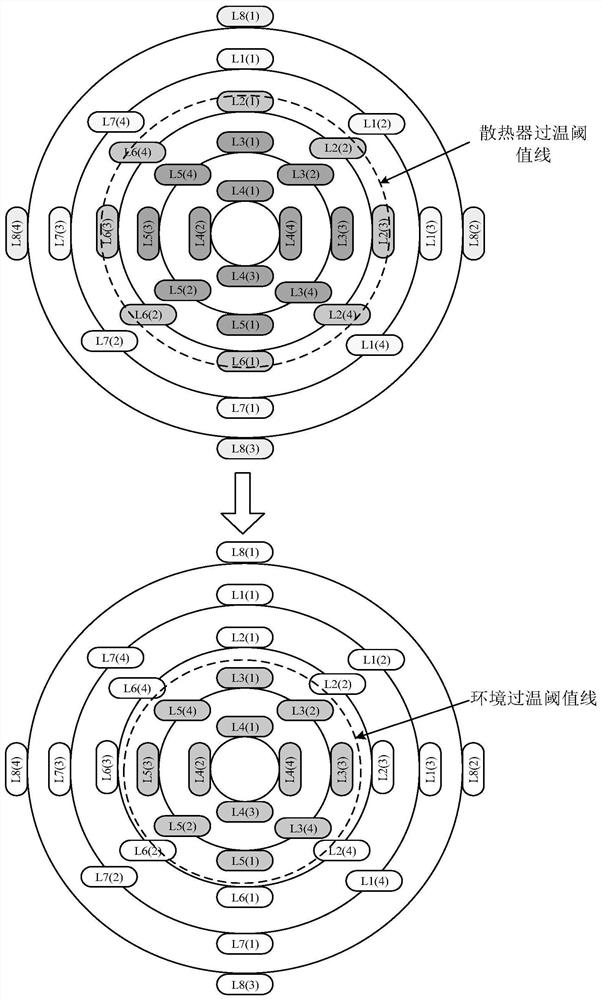

[0040] Such as figure 1 The valve tower temperature monitoring system shown includes a valve control unit, each thyristor-level thyristor control unit (TCE, also called TCU, Thytistor Controlled Unit) in the valve tower, and each thyristor control unit is provided with a radiator temperature acquisition interface and an ambient temperature Acquisition interface, the radiator temperature acquisition interface is connected with a radiator temperature sensor, and the radiator temperature sensor is arranged on the radiator in the thyristor stage in a patch type, such as Figure 4 As shown, it is used to determine the thyristor temperature by detecting the heat sink temperature.

[0041] The ambient temperature acquisition interface is connected with an ambient temperature sensor for detecting the ambient temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com