Tea cake pressing machine for yellow tea processing

A technology for pressing machine and tea cake, applied in the application, mixer, mixer accessories and other directions, can solve the problems of insufficient regular shape, uneven force on the tea cake, and difficulty in ensuring the uniform density of the tea cake, so as to improve the pressing quality, The effect of uniform density and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

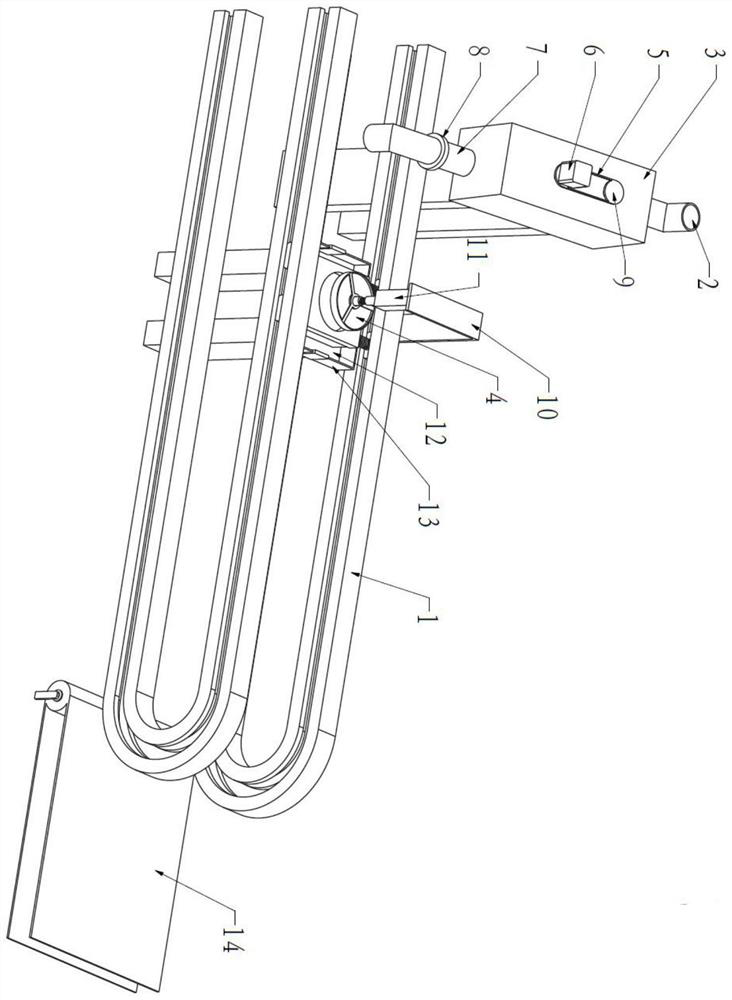

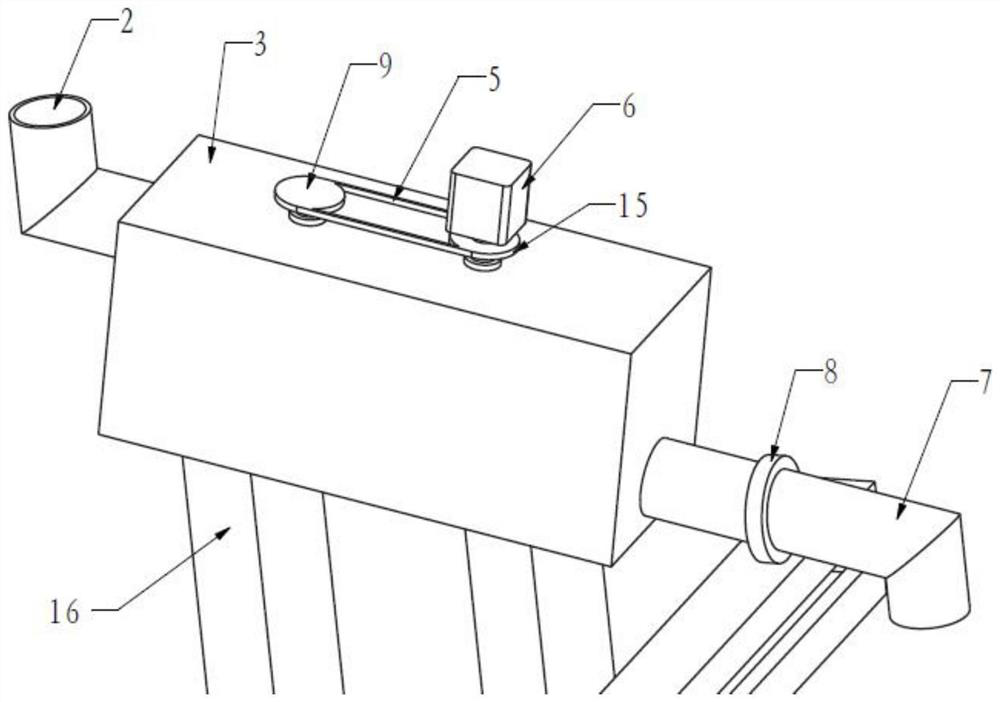

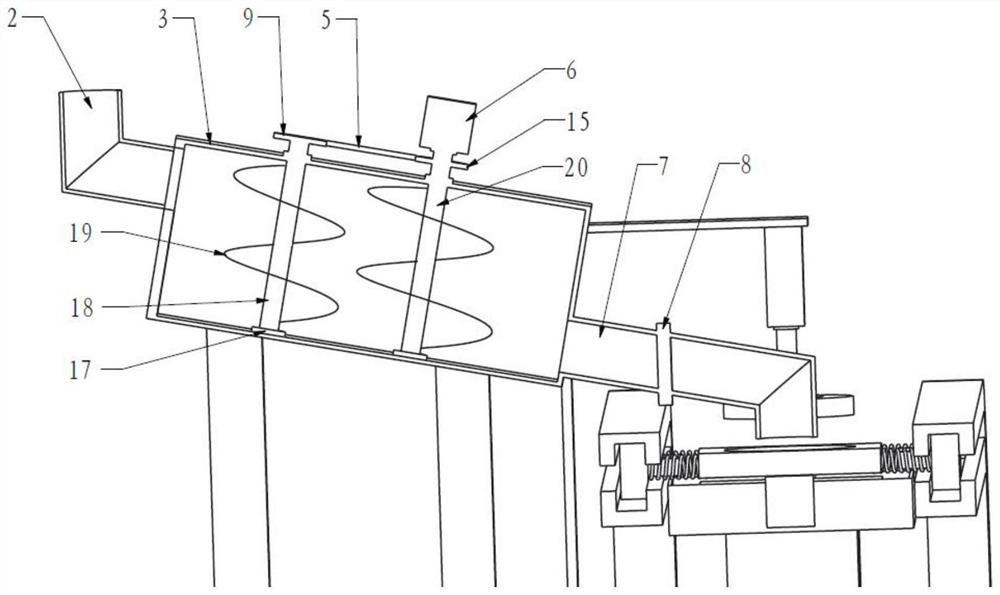

[0027] The present invention is further illustrated by the following examples.

[0028] A tea cake pressing machine for yellow tea processing, comprising a slide rail 1, rollers 27, a conveyor belt 14, and a feeding mixing box, the rolling wheels 27 are movably arranged in the slide rail 1, and the feeding mixing box is arranged on the Next to the slide rail 1, the feeding mixing box includes a mixing box 3, and the feed port 2 of the mixing box 3 enters the yellow tea material to be pressed. Feed into the material delivery assembly, the material delivery assembly includes a pressing bottom block 22, the two side walls of the pressing bottom block 22 are connected with the rollers 27 in the slide rail 1, the mixing box 3 is connected with the pressure head assembly 4, the The pressure head assembly 4 includes a pressure head 401, which is connected to the bottom end of the piston rod of the cylinder 11, and the cylinder 11 is supported by the support 10. A support block 24 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com