Granular organic fertilizer prepared from sludge and preparation method thereof

A granular organic fertilizer and sludge technology, which is applied in the direction of organic fertilizer, sewage/sludge fertilizer, bio-organic part treatment, etc., can solve the problems of short drug effect, dissolution, moisture absorption, etc., and achieve the recycling of resources from waste to treasure , Improve the effect of activity and nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

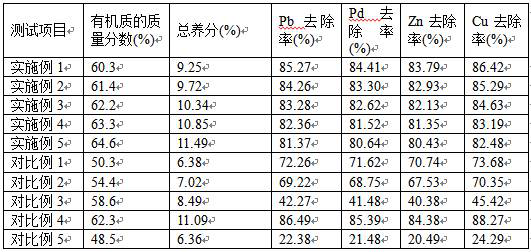

Examples

Embodiment 1

[0034] A granular organic fertilizer made from sludge, characterized in that it includes the following components in parts by weight: 46 parts of dried sludge, 12 parts of animal manure, 5 parts of active bacterial agents, 12 parts of rice husk powder, and 9 parts of oxidized starch clay Parts, durian shell-yuzu peel powder / allyl succinic anhydride / hyperbranched polyamido-amine (HBP-NH 2 ) 6 parts, xanthan gum multi-grafted paraffin emulsion 10 parts.

[0035] Further, the active bacterial agent is Bacillus subtilis.

[0036] Further, the preparation method of the oxidized starch clay is as follows: the oxidized starch and clay are prepared by melting, blending and ball milling for 24 hours, and the mass ratio of the oxidized starch and clay is 1:1.

[0037] Furthermore, durian shell-yuzu peel powder / allyl succinic anhydride / hyperbranched polyamide-amine (HBP-NH 2 ) preparation method, comprising the steps of:

[0038] Step I, preparation of durian shell-yuzu peel powder: p...

Embodiment 2

[0051] A granular organic fertilizer made from sludge, characterized in that it includes the following components in parts by weight: 49.5 parts of dried sludge, 11.5 parts of animal manure, 4.5 parts of active bacterial agent, 11.5 parts of rice husk powder, and 8.5 parts of oxidized starch clay Parts, durian shell-yuzu peel powder / allyl succinic anhydride / hyperbranched polyamido-amine (HBP-NH 2 ) 5.5 parts, xanthan gum multi-grafted paraffin emulsion 9 parts.

[0052] Furthermore, the active bacterial agent is yeast.

[0053] Furthermore, the preparation method of the oxidized starch clay is as follows: the oxidized starch and clay are prepared by melting, blending and ball milling for 27 hours, and the mass ratio of the oxidized starch and clay is 1:1.5.

[0054] Furthermore, durian shell-yuzu peel powder / allyl succinic anhydride / hyperbranched polyamide-amine (HBP-NH 2 ) preparation method, comprising the steps of:

[0055] Step I, preparation of durian shell-yuzu peel p...

Embodiment 3

[0068] A granular organic fertilizer made from sludge, characterized in that it includes the following components in parts by weight: 53 parts of dried sludge, 11 parts of animal manure, 4 parts of active bacterial agents, 11 parts of rice husk powder, and 8 parts of oxidized starch clay Parts, durian shell-yuzu peel powder / allyl succinic anhydride / hyperbranched polyamido-amine (HBP-NH 2 ) 5 parts, xanthan gum multi-grafted paraffin emulsion 8 parts.

[0069] Furthermore, the active bacterial agent is lactic acid bacteria.

[0070] Furthermore, the preparation method of the oxidized starch clay is as follows: the oxidized starch and clay are prepared by melting, blending and ball milling for 30 h, and the mass ratio of the oxidized starch and clay is 1:2.

[0071] Furthermore, durian shell-yuzu peel powder / allyl succinic anhydride / hyperbranched polyamide-amine (HBP-NH 2 ) preparation method, comprising the steps of:

[0072] Step I, preparation of durian shell-yuzu peel pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com