Dust removal device

A dust-removing device and a closed-type technology, which are used in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separating agents, can solve the problems of waste, insufficient strength, and large maintenance, and achieve the effect of small water consumption and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

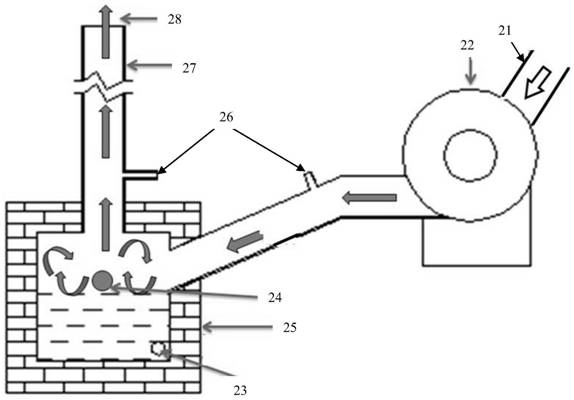

[0018] Attached below figure 2 , the specific implementation of the dust removal device provided by the embodiment of the present invention will be described in detail.

[0019] The embodiment of the present invention provides a dust removal device, the dust removal device is composed of a closed pool 25, a closed air passage, an air inlet pipe 21, an air outlet pipe 27, a sewage outlet 23 and a fan 22, and the two ends of the closed air passage are respectively connected to the closed Type pool 25 is connected with fan 22, air inlet pipe 21 is connected with fan 22, the upper part of the closed pool is connected with air outlet pipe 27, and the lower part of the closed pool is connected with sewage outlet 23; On the water surface of the closed pool 25, the water body forms a surge in the closed pool 25, so that the dust contacts with the surge and is absorbed by the water. The gas after dust removal is discharged through the air outlet pipe 27, and the fallen dust forms mudd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com