Energy-saving and environment-friendly plastic machining waste recovery device

A technology for waste recycling, energy saving and environmental protection, applied in plastic recycling, recycling technology, smoke and dust removal, etc., can solve the problems of affecting processing efficiency, troublesome collection and processing, time-consuming and labor-intensive, etc., to increase processing efficiency, facilitate storage, and reduce environmental pollution pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

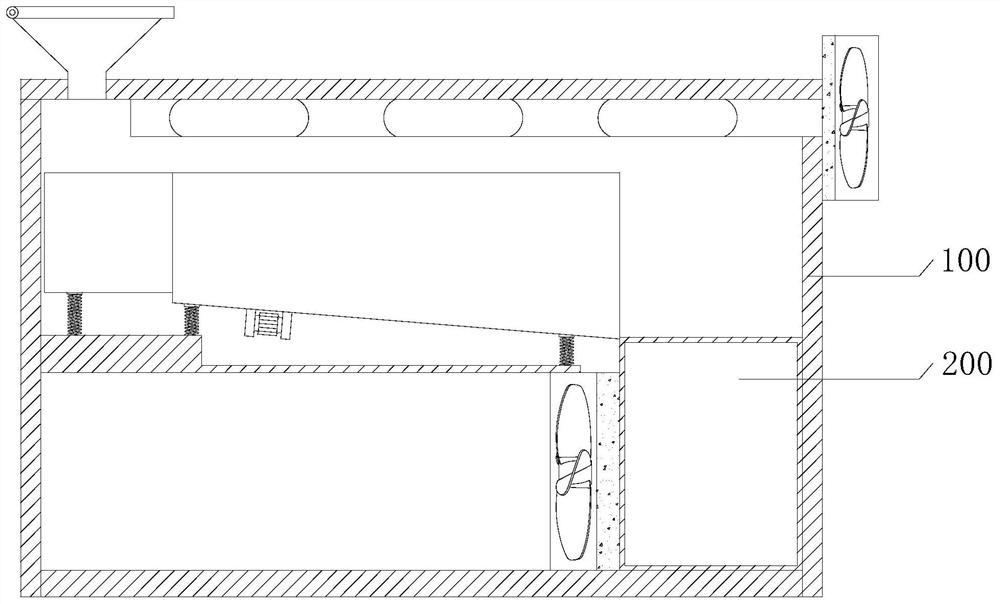

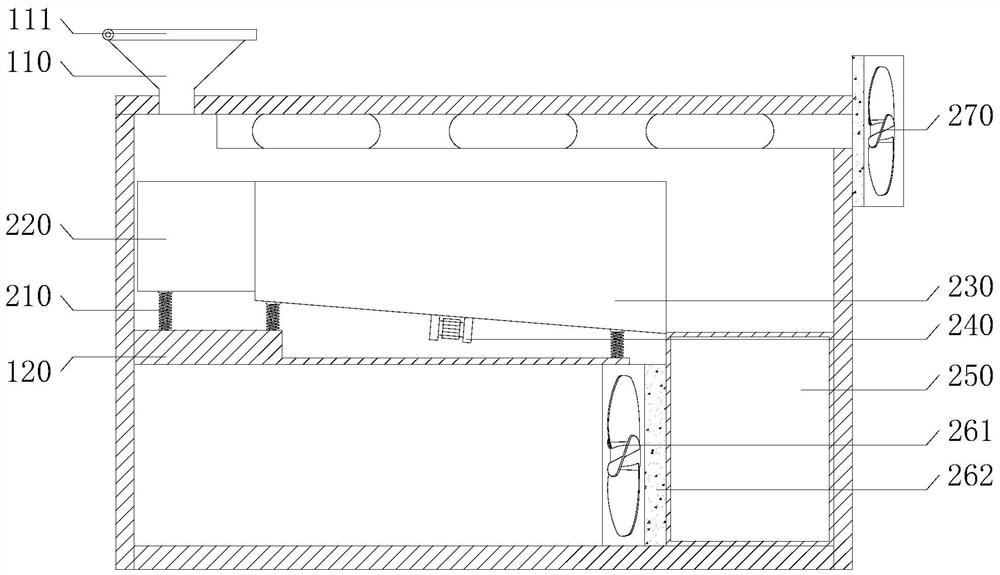

[0034] see figure 1 and figure 2 , the present invention provides a technical solution: an energy-saving and environment-friendly plastic processing waste recycling device, including a mounting frame 100 and a material distribution assembly 200 .

[0035]The top side of the mounting frame 100 is fixed with a lower hopper 110 by bolts, and the mounting frame 100 is fixedly connected with a fixing plate 120 by welding.

[0036] In some specific embodiments, the top of the lower hopper 110 is equipped with a dust cover 111 through screws, and the dust cover 111 is hinged to the lower hopper 110 to prevent dust from entering the storage box 220, and also to prevent the device from running. Dust or debris enters the air, causing environmental pollution and affecting the health of workers.

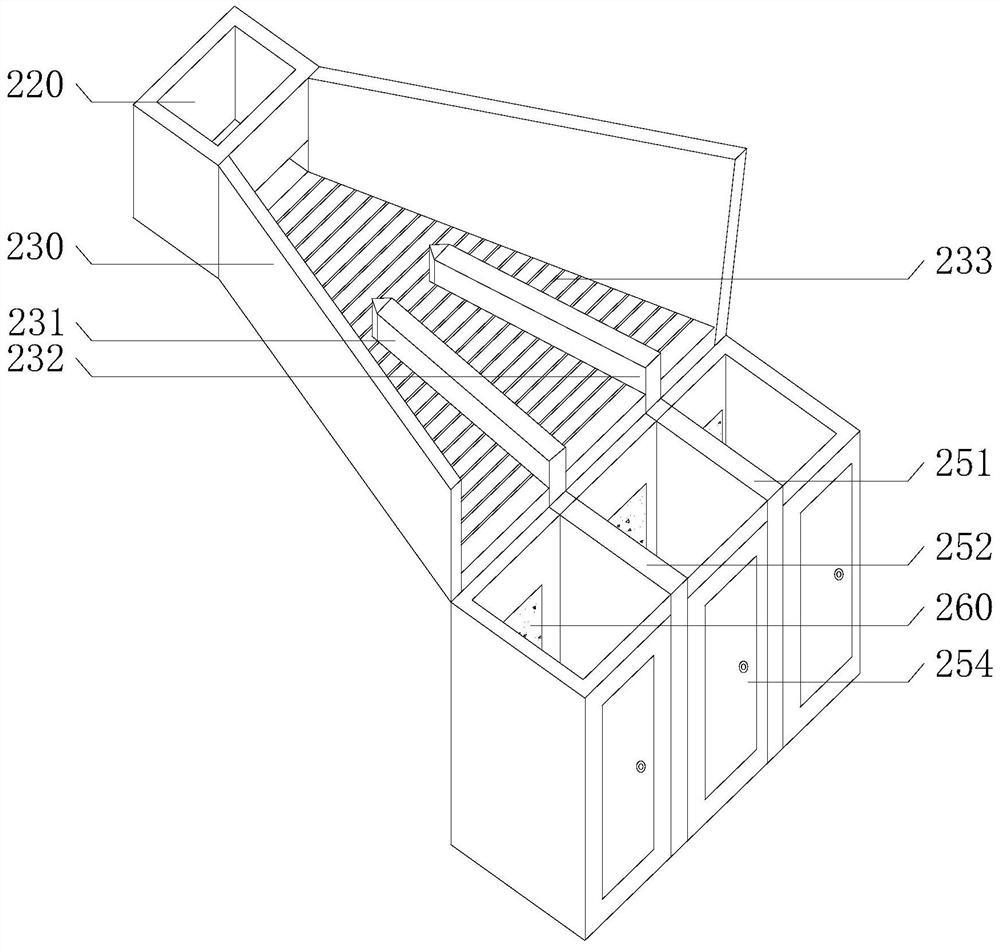

[0037] see Figure 2-Figure 4 , the material distribution assembly 200 includes an elastic member 210, a material storage box 220, a material distribution plate 230, a vibration motor 240 an...

Embodiment 2

[0047] see figure 1 and figure 2 , the present invention provides a technical solution: an energy-saving and environment-friendly plastic processing waste recycling device, including a mounting frame 100 and a material distribution assembly 200 .

[0048] The top side of the mounting frame 100 is fixed with a lower hopper 110 by bolts, and the mounting frame 100 is fixedly connected with a fixing plate 120 by welding.

[0049] In some specific embodiments, the top of the lower hopper 110 is equipped with a dust cover 111 through screws, and the dust cover 111 is hinged to the lower hopper 110 to prevent dust from entering the storage box 220, and also to prevent the device from running. Dust or debris enters the air, causing environmental pollution and affecting the health of workers.

[0050] see Figure 2-Figure 4 , the material distribution assembly 200 includes an elastic member 210, a material storage box 220, a material distribution plate 230, a vibration motor 240 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com