Waterproof and heat-insulating integrated board and construction process and online composite production process thereof

A production process and thermal insulation board technology, which is applied in the direction of thermal insulation, building thermal insulation materials, synthetic resin layered products, etc., can solve the problems of poor stability of waterproof and thermal insulation integrated panels, reduced waterproof and thermal insulation effect, and cumbersome production process, etc., to facilitate sales and The effect of promoting, increasing the surface area, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

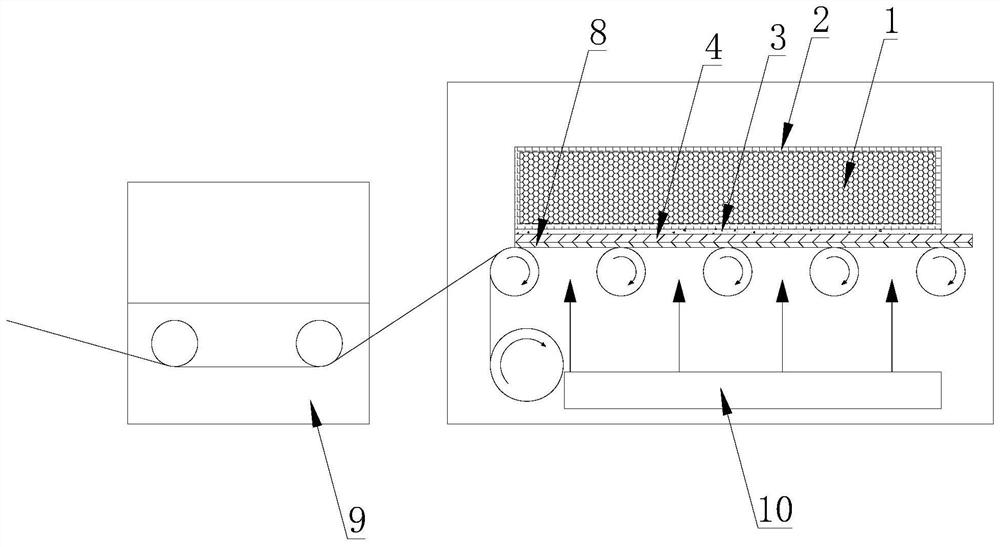

[0048] refer to Figure 1-5 , this embodiment discloses an online composite production process of a waterproof and thermal insulation integrated board, which includes the following steps:

[0049] Step 1: Roughen the surface of the insulation board 1 or / and treat it with an interface agent;

[0050] Step 2: Coating cement-based adhesive on at least one surface of the insulation board 1;

[0051] Step 3: The surface of the insulation board 1 coated with cement-based adhesive is covered with a film 8, and the film 8 includes a PE film, which plays the role of isolation and protection;

[0052] Step 4: The insulation boards 1 are stacked and placed in a constant temperature environment;

[0053] Step 5: During the production of the waterproof membrane, only one surface of the waterproof membrane is covered with the film 8;

[0054] Step 6: After the cement-based adhesive is cured, remove the film on the insulation board, and combine the surface of the insulation board 1 coated...

Embodiment 2

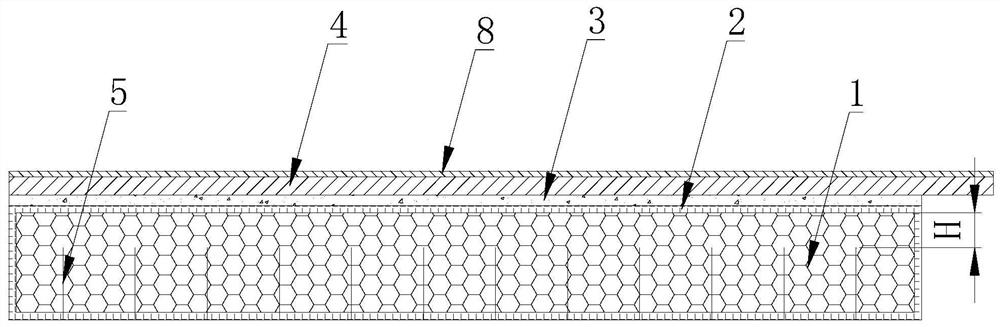

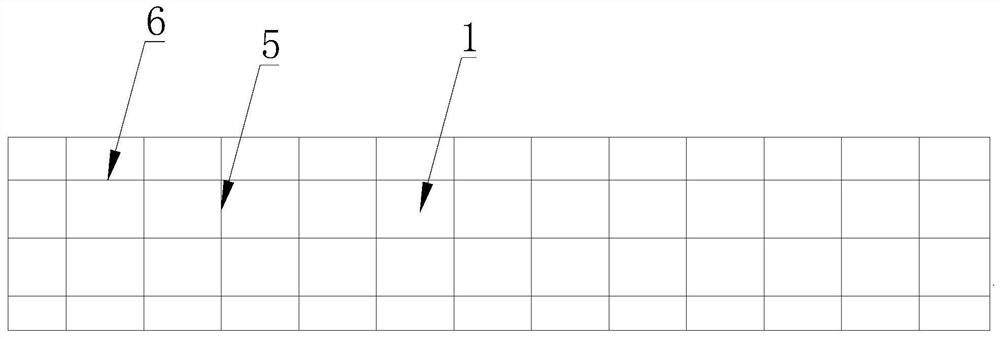

[0095] refer to Figure 2-3 , this embodiment discloses a waterproof and thermal insulation integrated board made by the above-mentioned online composite production process.

Embodiment 3

[0097] This embodiment discloses a construction process using the above-mentioned waterproof and thermal insulation integrated board, including the following steps:

[0098] S1: Coating waterproof paint on the base surface;

[0099] S2: Coating cement mortar on the surface of the cured waterproof coating or the surface of the waterproof and thermal insulation integrated board, the cement mortar includes polymer cement mortar or ordinary cement mortar;

[0100] S3: Lay the integrated waterproof and thermal insulation board on the base surface, then vibrate the integrated waterproof and thermal insulation board or fill the gap between two adjacent waterproof and thermal insulation integrated panels, and fill the gap between two adjacent waterproof and thermal insulation panels Lap edge treatment between integrated panels;

[0101] S4: Seal the gap between two adjacent waterproof and thermal insulation boards.

[0102] Further, S1 includes the following steps:

[0103] S1.1: B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com