Paper box packaging machine with drying function

A packaging machine and carton technology, applied in packaging and other directions, can solve problems such as unfavorable processing, excessive waste, affecting wafer cleanliness, etc., and achieve the effect of fast drying speed and reduced impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

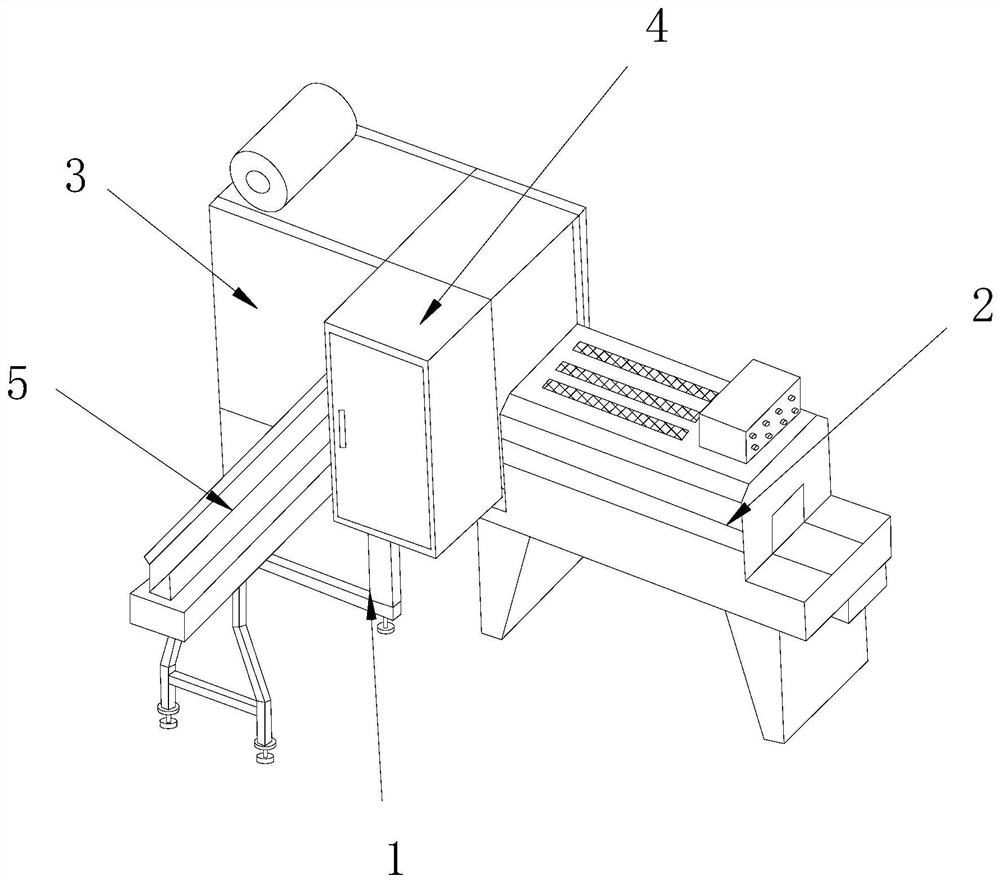

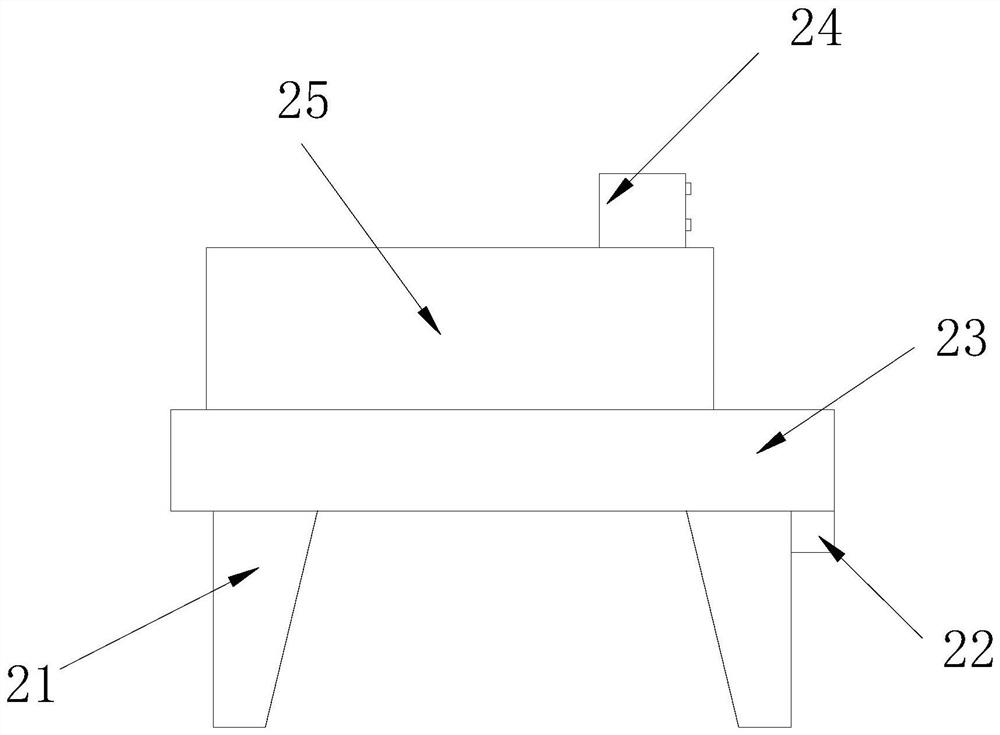

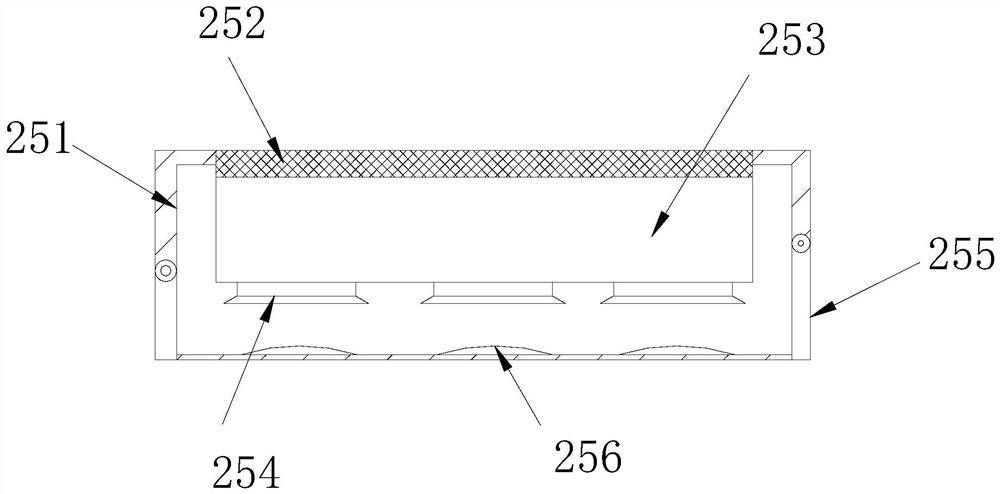

[0026] see Figure 1-Figure 5 , the specific embodiment of the present invention is as follows: a kind of carton packing machine with drying function, its structure comprises bracket 1, feeder 2, packer 3, electrical box 4, cardboard feeder 5, and described bracket 1 top The surface is welded and connected to the bottom surface of the wrapper 3, the back of the electric box 4 is welded to the front of the wrapper 3, the front of the wrapper 3 and the back of the cardboard feeder 5 are connected to each other and connected by electric welding, and the feeder 2 left The side and the right side of the packager 3 are connected to each other and connected by electric welding; the feeder 2 includes a pillar 21, a driver 22, an input platform 23, a control machine 24, and a drying bin 25, and the top surface of the pillar 21 is connected to the input The bottom surface of the platform 23 is welded and connected, the top surface of the driver 22 is fixedly installed on the bottom surf...

Embodiment 2

[0032] see Figure 6-Figure 8 The specific embodiments of the present invention are as follows: the extension plate A51 includes a connecting plate B1, an engaging groove B2, an elastic block B3, a wind-connecting plate B4, and a twist head B5, and the bottom surface of the connecting plate B1 and the engaging groove B2 are integrally formed. The top surface of the connecting plate B1 is connected to the bottom surface of the wind-connecting plate B4 through the elastic block B3, the right side of the connecting plate B1 is connected to the right side of the air-connecting plate B4 through the twist head B5, and the elastic blocks B3 are provided with four, four elastic blocks The gap of B3 is evenly distributed between the connecting plate B1 and the wind-connecting plate B4, which is beneficial to uniformly provide elastic support.

[0033] Wherein, the wind receiving plate B4 includes a plate body B41, a deceleration groove B42, a contact head B43, a receiving groove B44, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com