Low-reflectivity low-emissivity coated glass and preparation method thereof

A low-radiation coating, low reflectivity technology, applied in the coating and other directions, can solve the problem of high reflectivity, and achieve the effect of improving mechanical properties, low production cost, and protection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

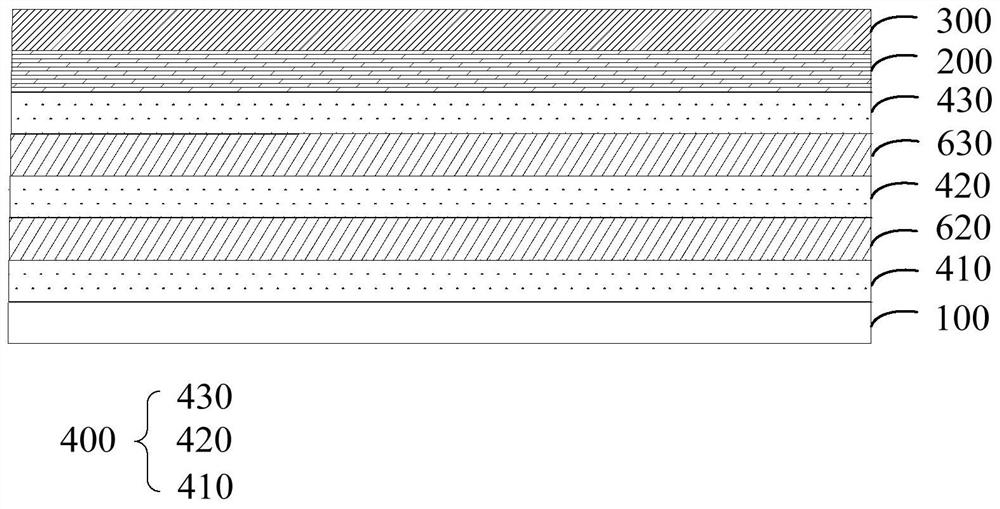

[0051] The present invention also proposes a method for preparing low-reflectivity low-emissivity coated glass, which is used to prepare the above-mentioned low-reflectivity low-emissivity coated glass. The preparation method includes the following steps: using a target material to perform vacuum magnetron sputtering on the surface of the glass base layer 100 in a vacuum environment, and sequentially sputtering to form an absorption layer 400, a second dielectric layer 620, a third dielectric layer 630, a functional layer 200 and The protective film layer 300, wherein the absorption layer 400 includes at least three protective layers, and the second dielectric layer 620 and the third dielectric layer 630 are respectively located between the two protective layers.

[0052] Specifically, the absorption layer 400 includes a first protective layer 410, a second protective layer 420, and a third protective layer 430, and the dielectric layer includes a first dielectric layer 610, a ...

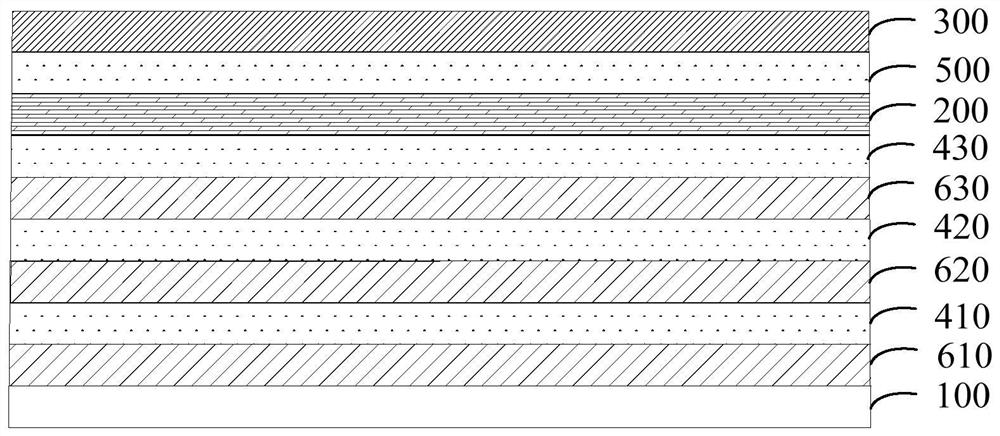

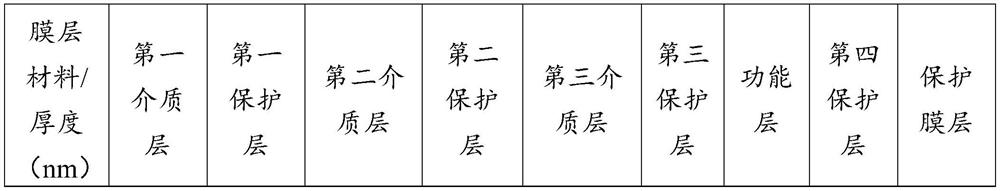

Embodiment 1

[0058] A low-reflectivity low-emissivity coated glass, including a first dielectric layer 610, a first protective layer 410, a second dielectric layer 620, a second protective layer 420, a third dielectric layer 630, and Three protective layers 430 , functional layer 200 , fourth protective layer 500 and protective film layer 300 . The first dielectric layer 610 is a SiNx layer with a thickness of 32.70nm; the first protective layer 410 is a NiCr layer with a thickness of 9.13nm; the second dielectric layer 620 is a ZnSnOx layer with a thickness of 38.30nm; the second protective layer 420 is NiCr layer with a thickness of 10.40nm; the third dielectric layer 630 is a ZnSnOx layer with a thickness of 40.30nm; the third protective layer 430 is a NiCr layer with a thickness of 2.87nm; the functional layer 200 is an Ag layer with a thickness of 10.03nm; the fourth protective layer The layer 500 is a NiCr layer with a thickness of 2.87nm; the protective film layer 300 is a SiNx laye...

Embodiment 2

[0062] A low-reflectivity low-emissivity coated glass, including a first dielectric layer 610, a first protective layer 410, a second dielectric layer 620, a second protective layer 420, a third dielectric layer 630, and Three protective layers 430 , functional layer 200 , fourth protective layer 500 and protective film layer 300 . The first dielectric layer 610 is a SiNx layer with a thickness of 28.70nm; the first protective layer 410 is a NiCr layer with a thickness of 10.97nm; the second dielectric layer 620 is a ZnAlOx layer with a thickness of 45.10nm; the second protective layer 420 is NiCr layer and Cu layer, the thicknesses are 4.52nm and 4.00nm respectively; the third dielectric layer 630 is a ZnAlOx layer, the thickness is 47.50nm; the third protective layer 430 is a NiCr layer, the thickness is 4.02nm; the functional layer 200 is an Ag layer, the thickness The fourth protective layer 500 is a NiCr layer with a thickness of 4.02nm; the protective film layer 300 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com