High-energy acoustic beam regulation and control device for residual stress of annular workpiece

A ring-shaped workpiece and residual stress technology, applied in the direction of improving process efficiency, etc., to achieve the effects of convenient production, improved conduction efficiency, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

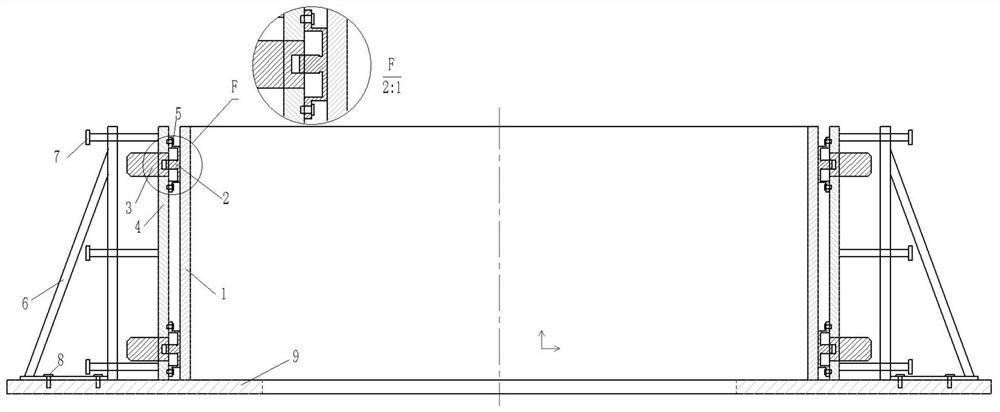

[0023] combine figure 1 , the invention discloses a high-energy sound beam regulating device for residual stress of an annular workpiece, comprising an excitation wedge 2, a high-energy sound beam exciter 3, an exciter mounting plate 4, a fixing bolt 5, a triangular support frame 6, a tightening bolt 7, Install bolt 8 and base 9.

[0024] combine figure 1 , the triangular support frame 6 is fixed on the base 9 through the mounting bolt 8, the tightening bolt 7 passes through the threaded hole on the triangular support frame 6 to tighten the exciter mounting plate 4, and the excitation wedge is installed on the exciter mounting plate through the fixing bolt 5 4, the high-energy sound beam exciter 3 is screwed together through the tail of the excitation wedge 2, and lubricating grease is applied between the arc surface of the excitation wedge 2 and the annular workpiece 1.

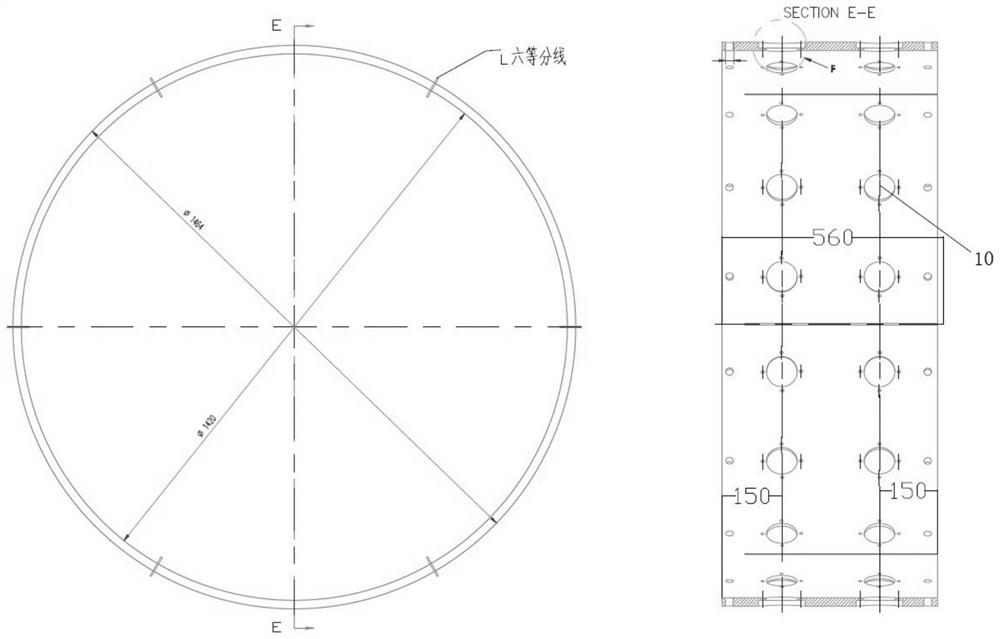

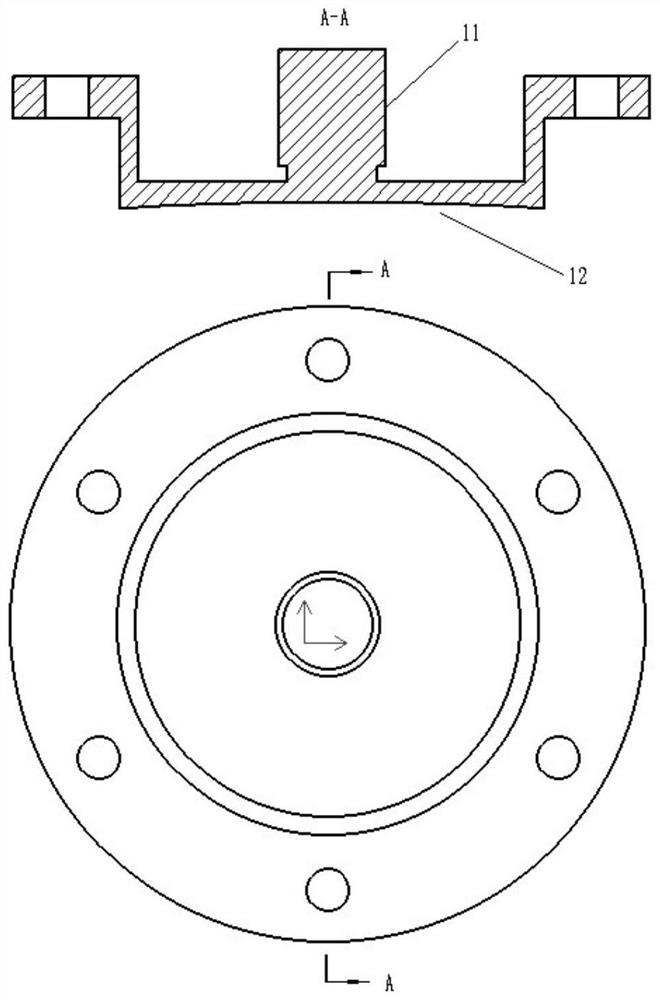

[0025] combine figure 2 , the left figure is the top view of the exciter mounting plate 4, and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com