Thin type layered composite solid electrolyte membrane and preparation method and application thereof

A solid electrolyte membrane, layered composite technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of discontinuous grains, large grain boundary impedance, limiting membrane processing, etc., and achieve regular and continuous arrangement orientation, The effect of improving energy density and good interlayer channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a thin layered composite solid electrolyte membrane, the preparation method comprising the following steps:

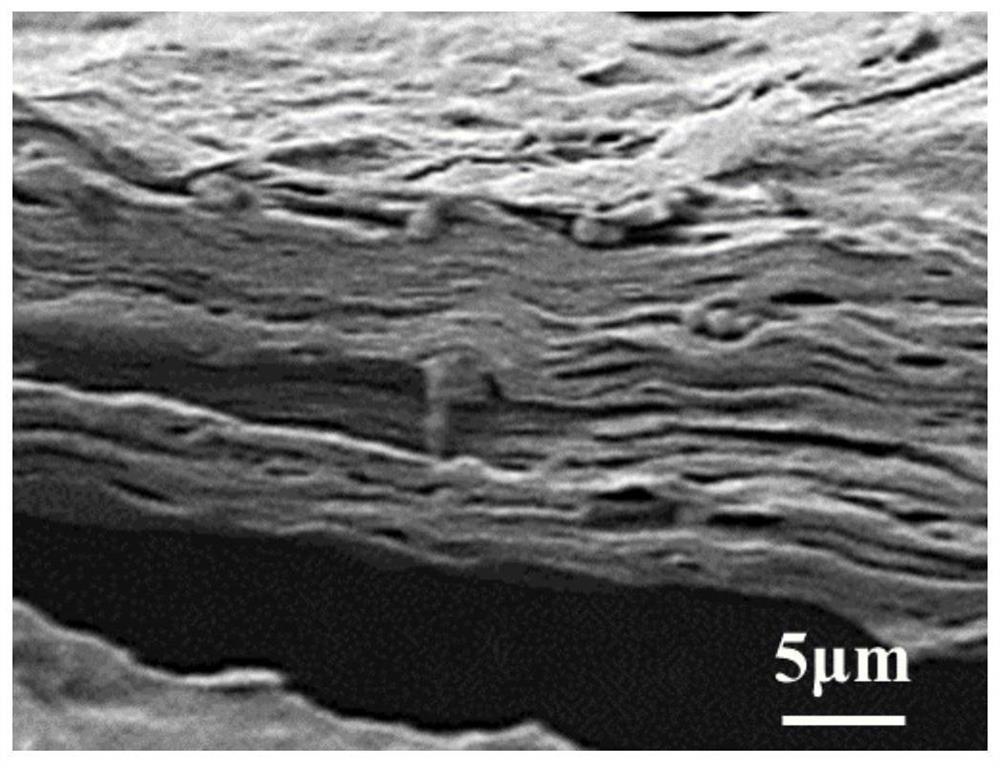

[0041] 1) Using thermally expanded vermiculite as a raw material, vermiculite nanosheets were prepared by a two-step ion exchange method. The specific experimental steps are as follows: add 2 g of heat-expandable vermiculite (particle size: 8-13 mm) to saturated NaCl solution, stir magnetically at 120 ° C for 48 hours, and then wash with deionized water for 5 times to obtain the expanded vermiculite intercalated with sodium ions. Then, the expanded vermiculite intercalated with sodium ions was continued to reflux in 2M LiCl solution for 24 hours (oil bath temperature: 120°C), then filtered and washed 5 times with deionized water and 3 times with absolute ethanol until No Cl was detected in the filtrate - So far, the expanded vermiculite with lithium ion intercalation is obtained; take 0.5g of expanded vermiculite with lithium ion interca...

Embodiment 2

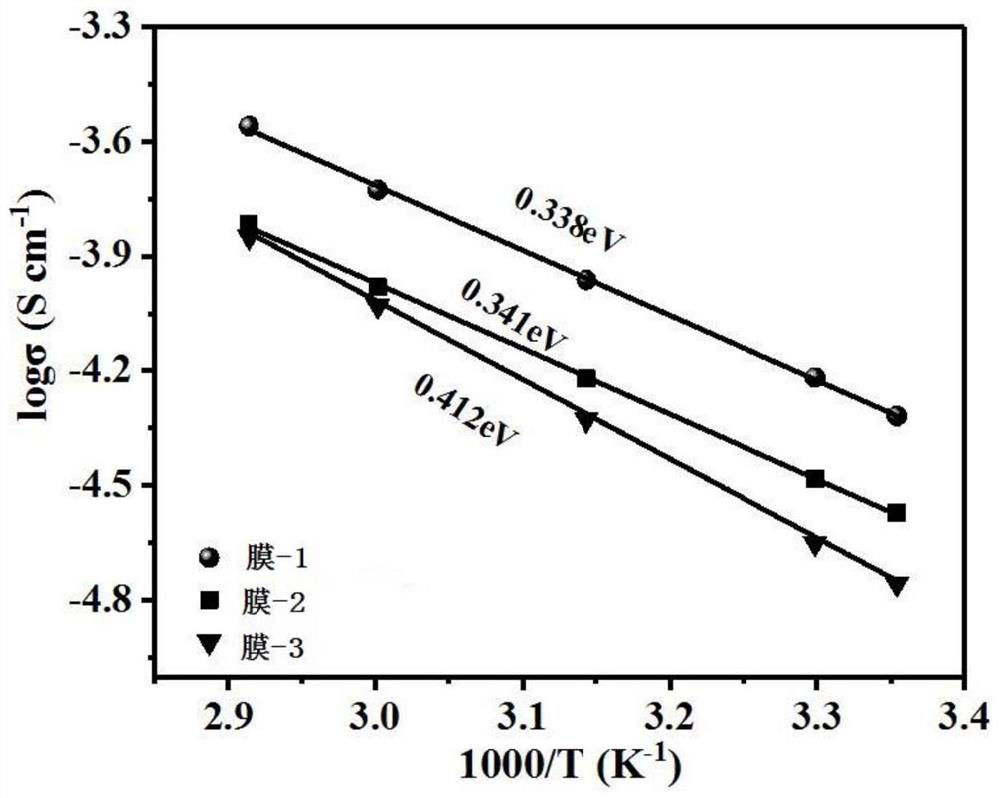

[0045] In step 1), take 125mL of the vermiculite nanosheet dispersion and add it to a suction filtration device for suction filtration, and the remaining steps and parameters are the same as in Example 1. A thin layered composite solid electrolyte membrane with a film thickness of 100 μm was prepared, which was designated as Membrane-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com