A control method of high-power rlc AC electronic load

A technology of electronic load and control method, applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve problems such as difficulty in satisfying simulation, steady-state waveform lag, and low dynamic response, and achieve The effect of reducing system cost, small steady-state phase shift, and simple hardware circuit topology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

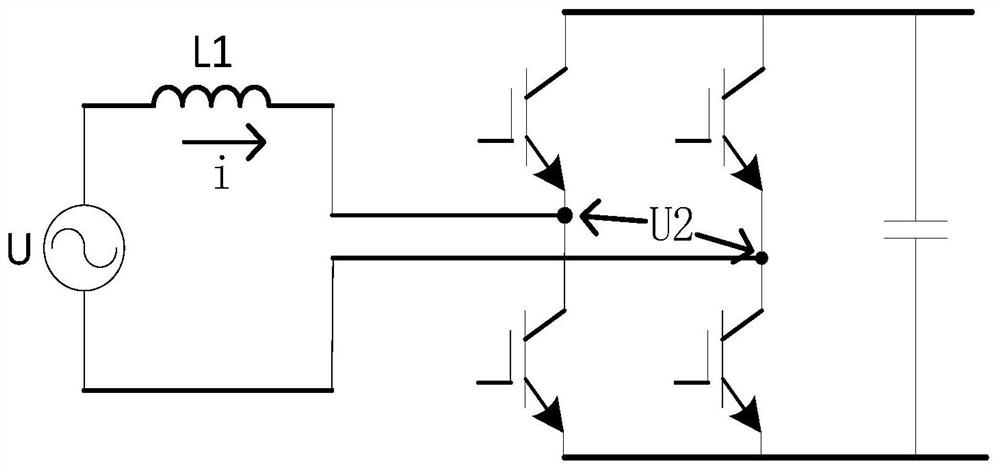

[0065] like figure 1 As shown, the main circuit of a high-power RLC AC electronic load includes an AC voltage source U, a filter inductor L1, an H-bridge circuit, and a controlled voltage source U2; the output of the AC voltage source U is connected to the H-bridge circuit through a filter inductor L1 The midpoint of the two bridge arms, the controlled voltage source U2 is the voltage output by the midpoint of the two bridge arms of the H bridge circuit, and the power switch tube of the H bridge circuit adopts IGBT.

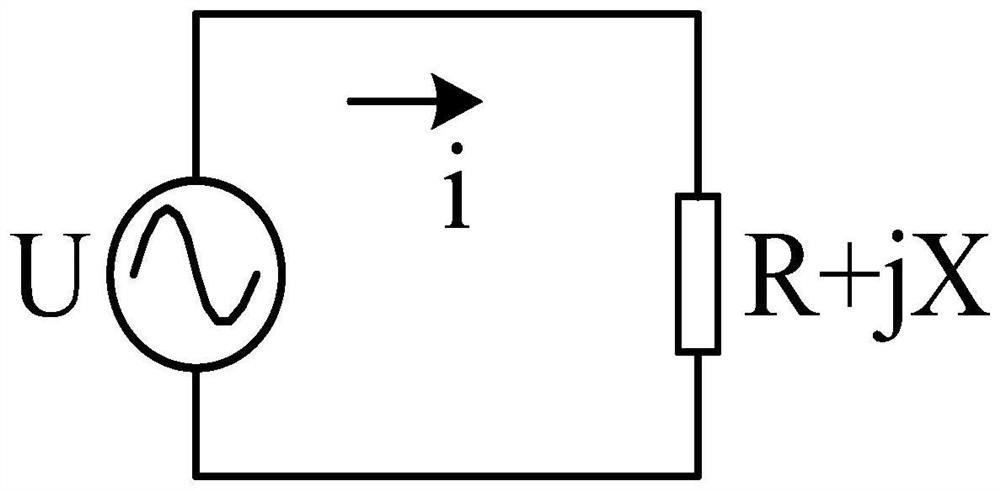

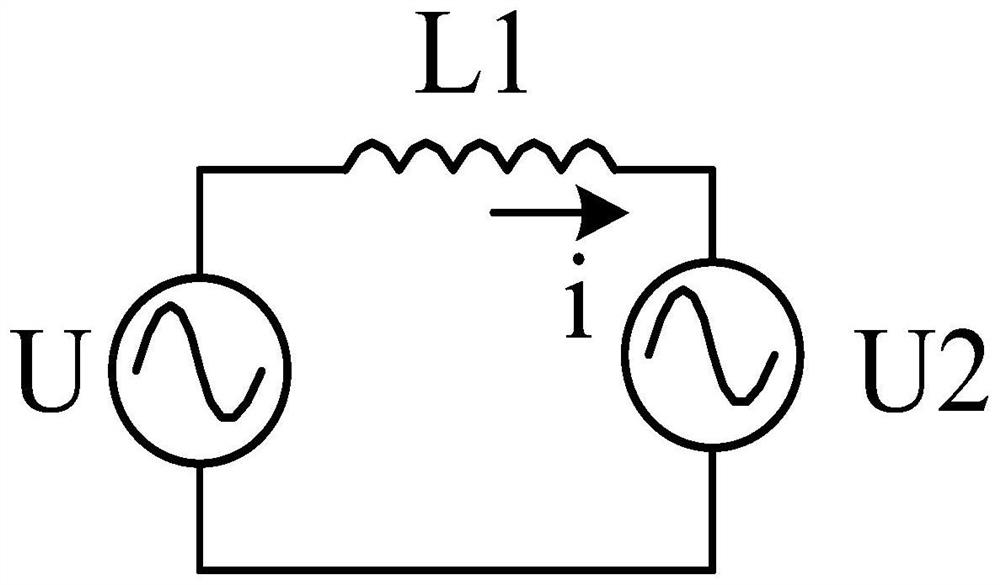

[0066] such as with figure 1 corresponding figure 2 and image 3 Shown, the RLC AC electronic load ideal model and actual model based on voltage control; The equivalent circuit of the RLC AC electronic load ideal model based on voltage control includes: AC voltage source U, analog load (R+jX load); The output end of the AC voltage source U is directly connected to the analog load to form a closed loop. The equivalent circuit of the actual model of the RLC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com