A kind of thorn and impurity removal device and method for removing thorns and impurities for thorn pear processing

A technology for thorn pears and miscellaneous boxes, which is applied in the field of thorn pear removal and impurity removal devices for processing thorn pears, can solve the problems affecting the effect and efficiency of burr removal of thorn pears, poor impurity removal effect, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

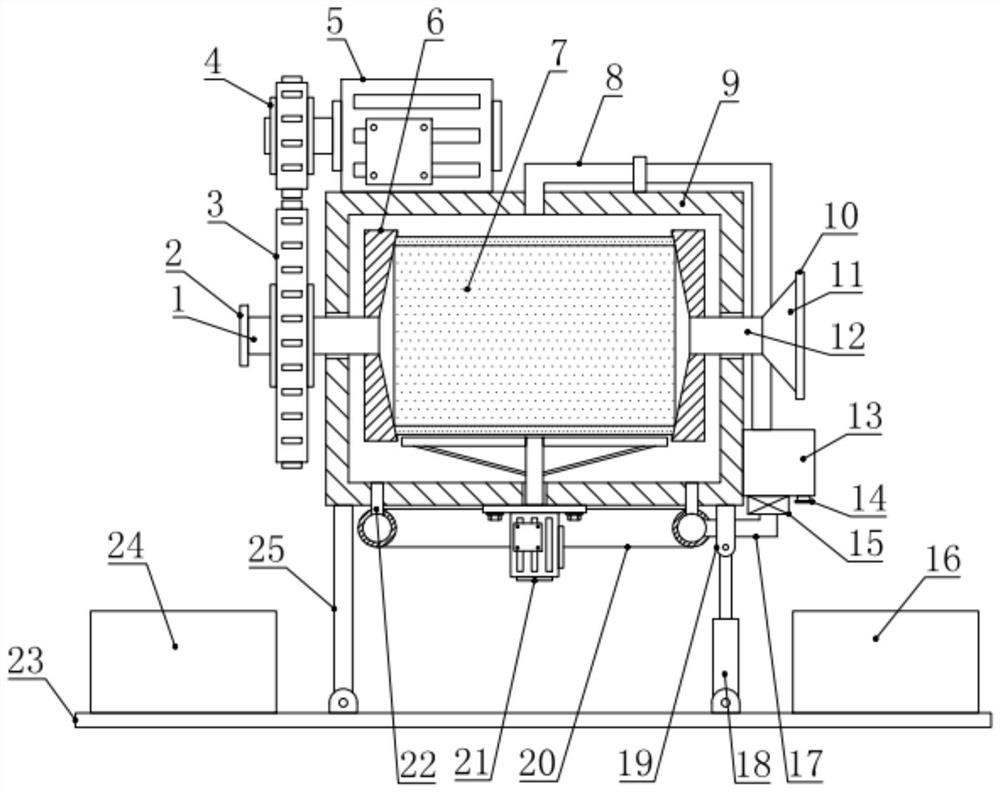

Embodiment 1

[0023] see figure 1 , in an embodiment of the present invention, a prickly pear processing device for removing thorns and impurities, including a processing body 9 and a base plate seat 23, the processing body 9 is erected above the base plate base 23 through an angle adjustment assembly, and the inside of the processing body 9 Be provided with porous net tube 7, the two ends of porous net tube 7 are all provided with end baffles 6, the outer sides of two end baffles 6 are respectively equipped with discharge transfer tube 1 and feed transfer tube 12, described processing The outside of the machine body 9 is also equipped with a driving assembly for driving the integral rotation of the discharge rotary tube 1, the end baffle plate 6, the porous net tube 7 and the feed rotary tube 12. The lower side of the porous net tube 7 is also matched with A cutting assembly is provided, and the outer bottom of the processing body 9 is provided with a second motor 21 for driving the cuttin...

Embodiment 2

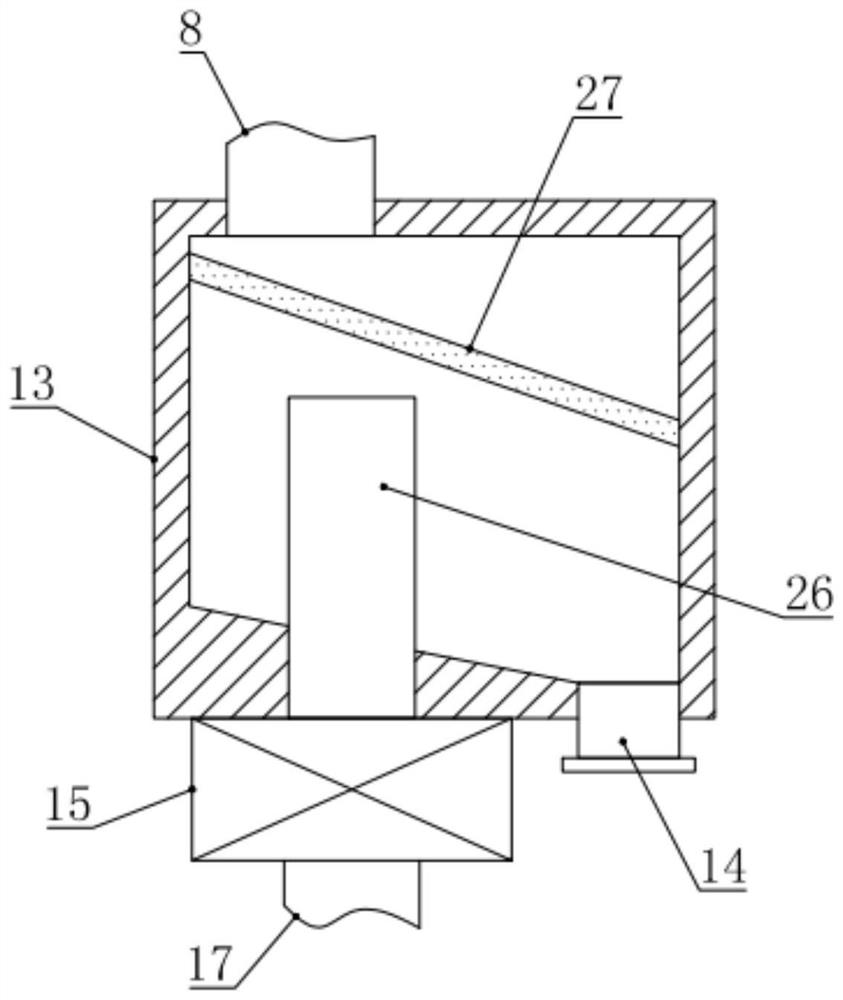

[0026] see Figure 1-3 , the difference between this embodiment and embodiment 1 is:

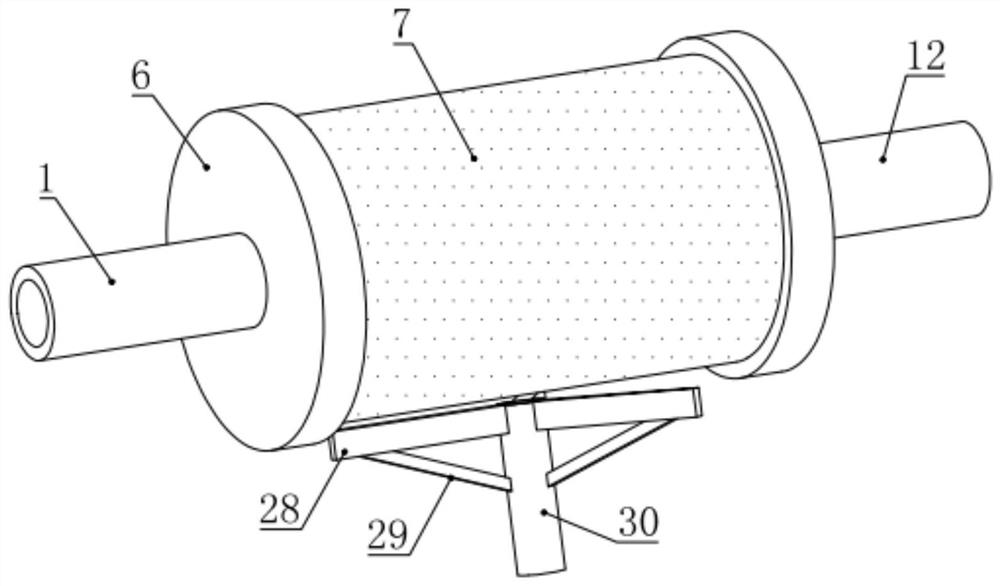

[0027] In this embodiment, the porous mesh cylinder 7 is a cylindrical cylinder structure, and the end baffle plate 6 is set at an inclination in the middle to the side away from the porous mesh cylinder 7, which facilitates the addition and discharge of raw materials. 1 and the feeding rotary tube 12 are arranged horizontally and coaxially. Both the discharging rotary tube 1 and the feeding rotary tube 12 are rotatably connected with the side wall of the processing machine body 9. The end of the discharging rotary tube 1 is also equipped with a discharge Sealing cover 2, feeding hopper 11 is also installed at the end of feeding transfer tube 12, and feeding sealing cover 10 is installed at the end of feeding hopper 11, plays a sealing role through discharging sealing cover 2 and feeding sealing cover 10 , to avoid affecting the normal work of the circulating air impurity removal assembly; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com