Anti-explosion dust removal device for grain production and processing

A dust removal device and grain technology, applied in the field of grain processing, can solve the problems of explosion, grain dust, poor safety, etc., and achieve the effects of convenient use, improved safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

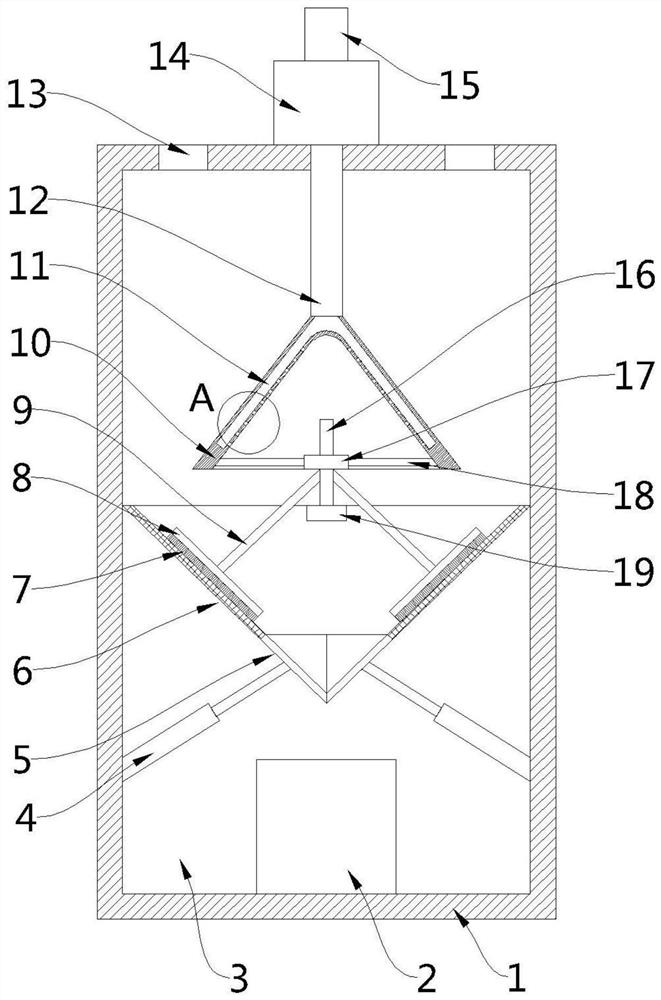

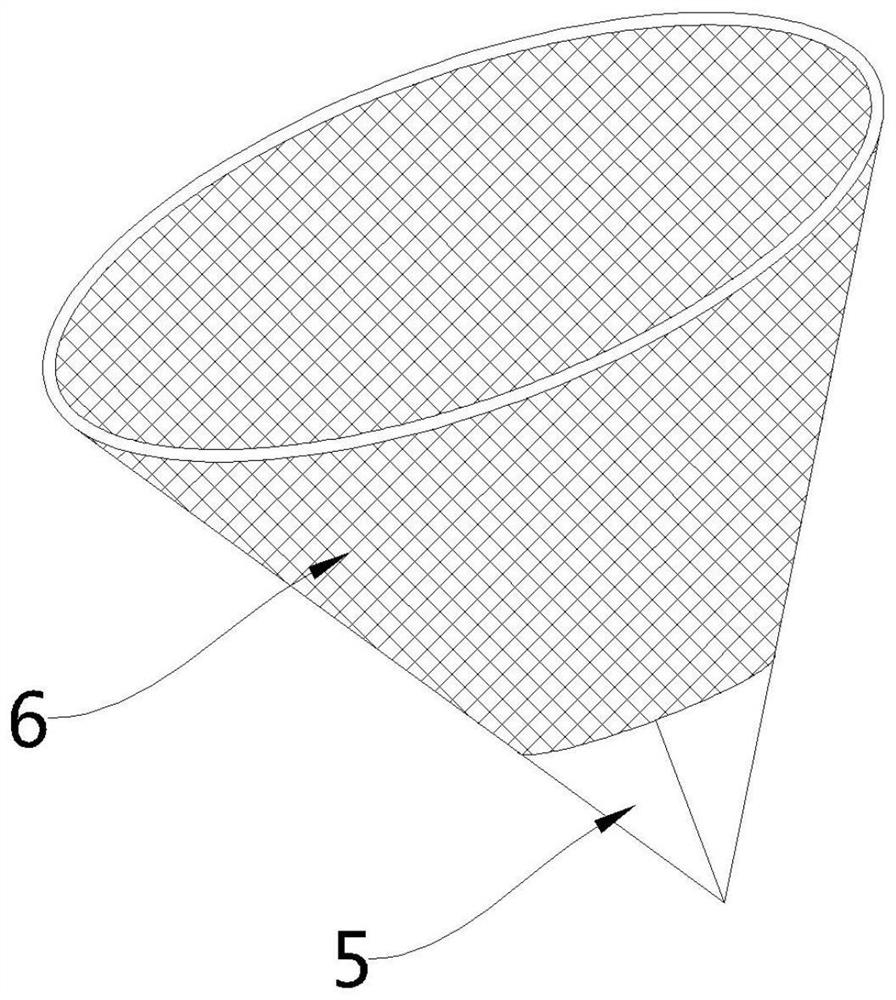

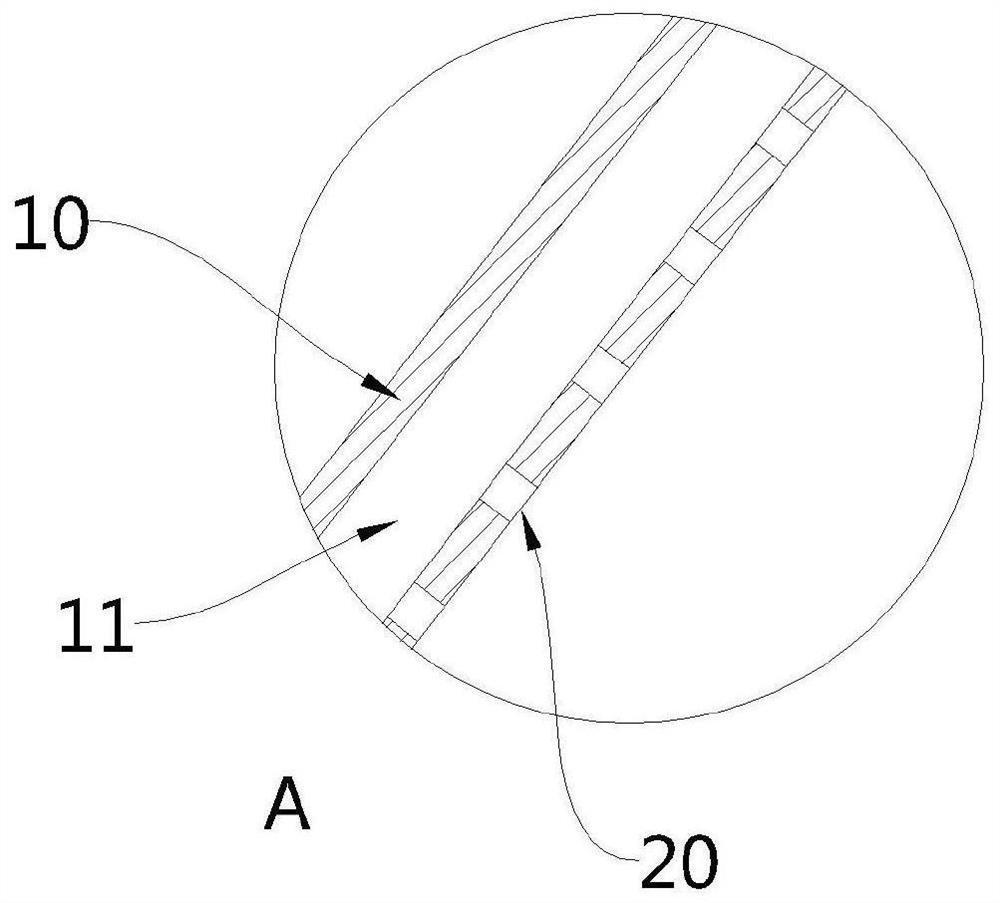

[0024] see Figure 1-3 , the present embodiment provides an explosion-proof dust removal device for grain production and processing, including a box body 1, a dust collection box 14 is fixedly arranged on the upper part of the box body 1, and a feed inlet 13 is opened on the upper part of the box body 1, and the inside of the box body 1 A screening assembly for filtering the grain and a dust suction assembly for collecting the grain dust into the dust collection box 14 are provided. Specifically, the screening assembly includes partitions 6 distributed in an annular shape and hinged on the The two groups of bases 5 at the bottom of the partition 6, the bases 5 of the two groups can rotate along the bottom of the partition 6 and form an upward conical structure with the partition 6, and the inside of the box body 1 is provided with a structure for driving the two groups of bases 5 Relative to the rotating power assembly 4, the inner wall of the partition 6 is fitted with a clea...

Embodiment 2

[0033] see figure 1 , an explosion-proof dust removal device for grain production and processing. Compared with Embodiment 1, the inner bottom of the box body 1 is also provided with a material receiving box 2 corresponding to the base 5 in this embodiment. The material receiving box 2 Upper exposure setting.

[0034] Through the setting of the material receiving box 2, after the base 5 is rotated and opened, the grains located inside the base 5 can be discharged into the material receiving box 2 for storage.

[0035] Further, a grain storage area 3 for storing grain grains is provided outside the material receiving box 2 .

[0036] The embodiment of the present invention has the advantages of simple structure, convenient use, and good dust removal effect. The dust generated during the grain screening process is absorbed by the dust suction assembly to avoid excessive accumulation of dust inside the box 1, which in turn leads to dust concentration. The height is increased, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com