A Fabrication Method of Surface Enhanced Raman Scattering Substrate Based on Aluminum Nitride Nanostructure

A surface-enhanced Raman and nanostructure technology, applied in the field of nanomaterials, can solve the problems of unfavorable mass production of disposable SERS substrates, small longitudinal depth of nanostructures on the substrate surface, cumbersome preparation process, etc., to reduce detection costs, The effect of low cost and high process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

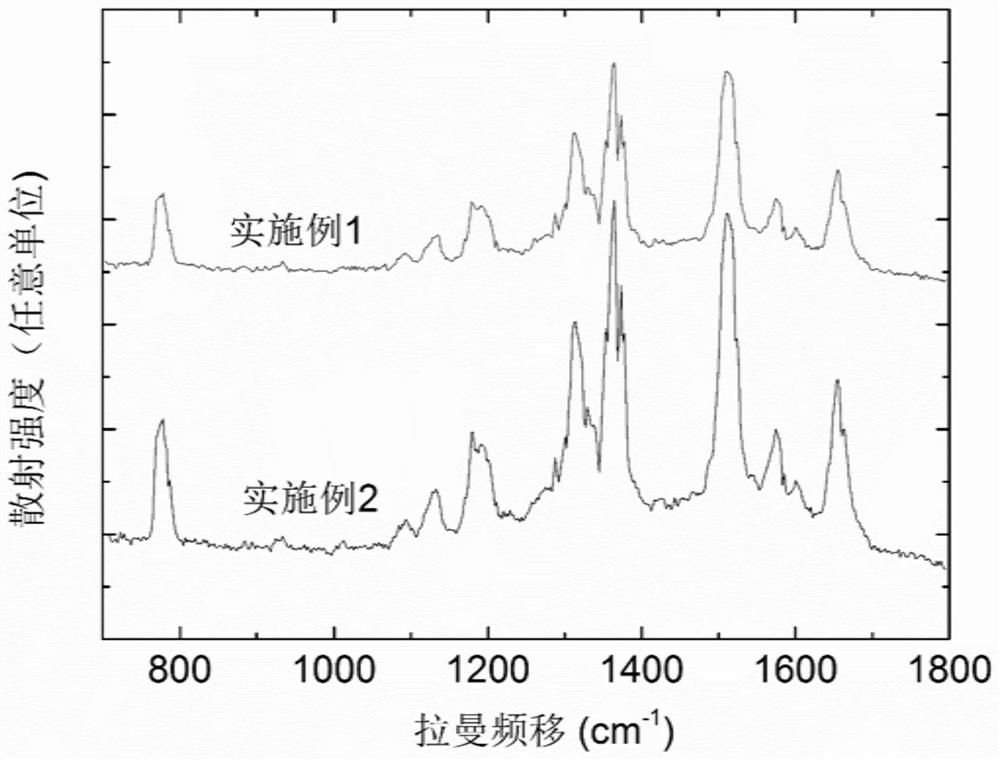

Embodiment 1

[0043] A method for manufacturing a surface-enhanced Raman scattering substrate based on aluminum nitride nanostructures, comprising the following steps:

[0044] (1) Prepare the glass substrate and clean and dry it;

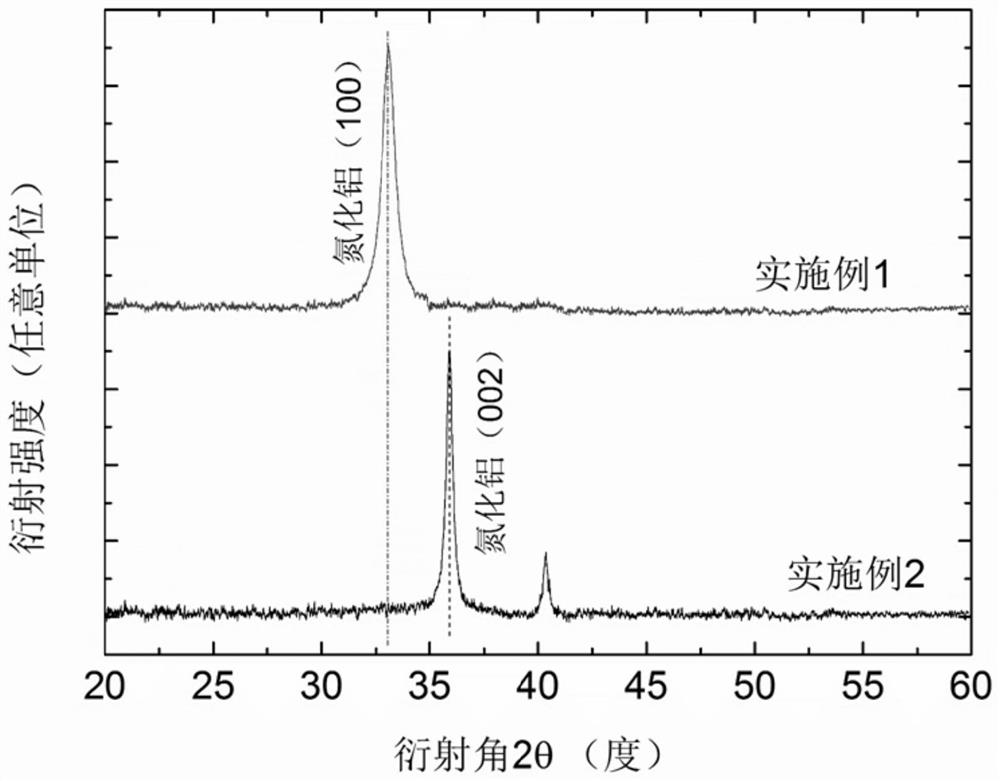

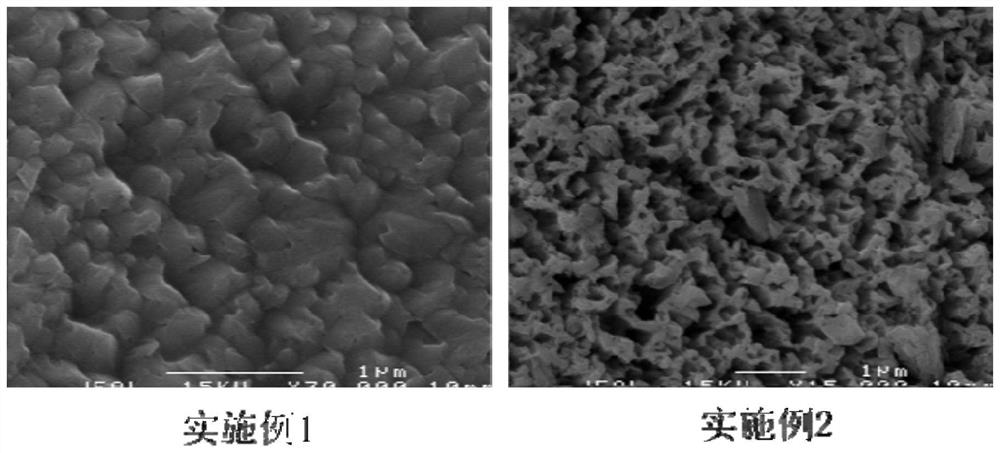

[0045] The aluminum nitride film with (100) texture is prepared on the substrate by magnetron sputtering method, the thickness is 100nm, and the process flow is as follows:

[0046] (i) Magnetron sputtering background vacuum pumped to less than 10 -3 Pa.

[0047] (ii) Applying a reverse bias voltage to perform plasma bombardment cleaning on the surface of the glass substrate to increase the binding force with the aluminum nitride film.

[0048] (iii) Use a high-purity aluminum target for reactive sputtering in a mixed atmosphere of nitrogen and argon. The preferred process parameters are: the volume ratio of nitrogen and argon is 7:3, the pressure of the sputtering atmosphere is 5Pa, and the sputtering power density is 4W / cm 2 .

[0049] (iv) After the spu...

Embodiment 2

[0057] A method for manufacturing a surface-enhanced Raman scattering substrate based on aluminum nitride nanostructures, comprising the following steps:

[0058] (1) Prepare the glass substrate and clean and dry it;

[0059] The aluminum nitride film with (002) texture is prepared on the substrate by magnetron sputtering method, the thickness is 200nm, and the process flow is as follows:

[0060] (i) Magnetron sputtering background vacuum pumped to less than 10 -3 Pa.

[0061] (ii) Applying a reverse bias voltage to perform plasma bombardment cleaning on the surface of the glass substrate.

[0062] (iii) Sputtering deposited tungsten metal with a thickness of 100 nanometers as a lattice mismatch buffer layer between (002) textured aluminum nitride and glass;

[0063] Use high-purity aluminum targets for reactive sputtering in a mixed atmosphere of nitrogen and argon, the volume ratio of nitrogen and argon is 2:8, the pressure of the sputtering atmosphere is 0.5Pa, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com