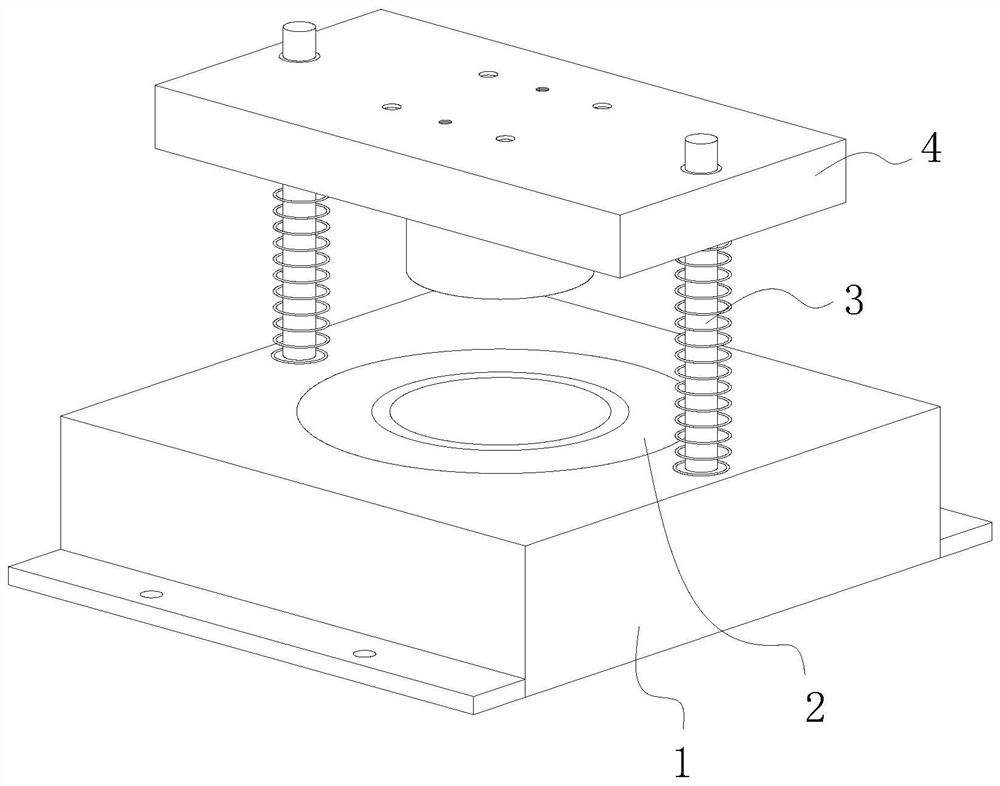

Molding processing system for circular sheet-iron packaging box

A technology for molding processing and packaging boxes, applied in the direction of molding tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high replacement cost, damaged screw holes, and increased waste of resources, etc., to achieve convenient pin positions and increase frictional resistance , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

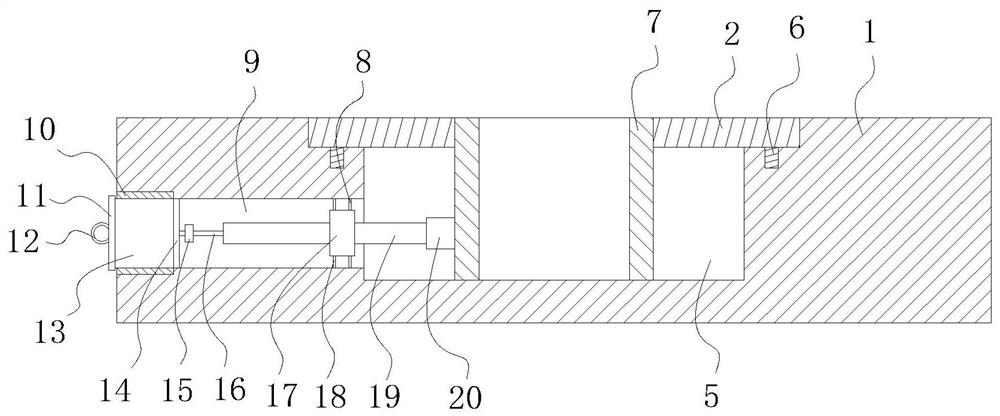

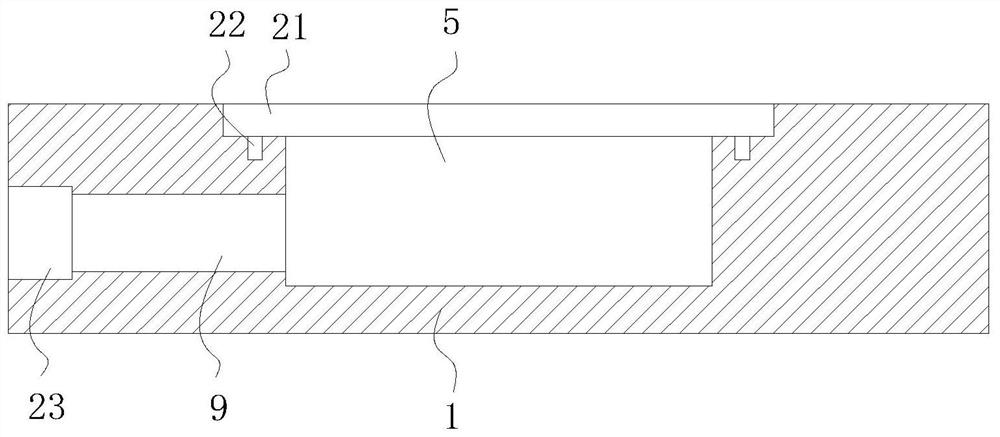

[0038] Specific implementation: After installing the molding die 7 in the cavity 5 on the base 1, the positioning sleeve 20 is aligned with the square hole 9, and then the pin 19 is inserted in the positioning sleeve 20. At this time, the rubber plug 13 is in the rubber In the sleeve 10, it plays the role of increasing the frictional resistance. The pin 19 is prevented from falling from the positioning sleeve 20 at will. The position of the forming die 7 is fixed by the cooperation of the pin 19 and the positioning sleeve 20. In this way, there is no damage to the screw holes, avoiding the situation of replacing the entire base 1, and reducing the waste of resources.

[0039] When the size of the molding die 7 installed in the cavity 5 becomes larger or smaller, the distance between the positioning sleeve 20 and the square hole 9 is reduced or increased. At this time, the threaded column 16 is screwed to make the screw thread of the threaded column 16 on the pin 19 The length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com