Welding machine with welding fume multiple collecting and filtering mechanism and filtering method

A filtering mechanism and multiple technologies, applied in separation methods, chemical instruments and methods, manufacturing tools, etc., can solve problems such as easy falling of electric sparks into the suction head, easy scattering of welding fumes, and damage of internal components, etc., to achieve Avoid spilling everywhere, prevent sparks from entering, and prevent the effect of excessive gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

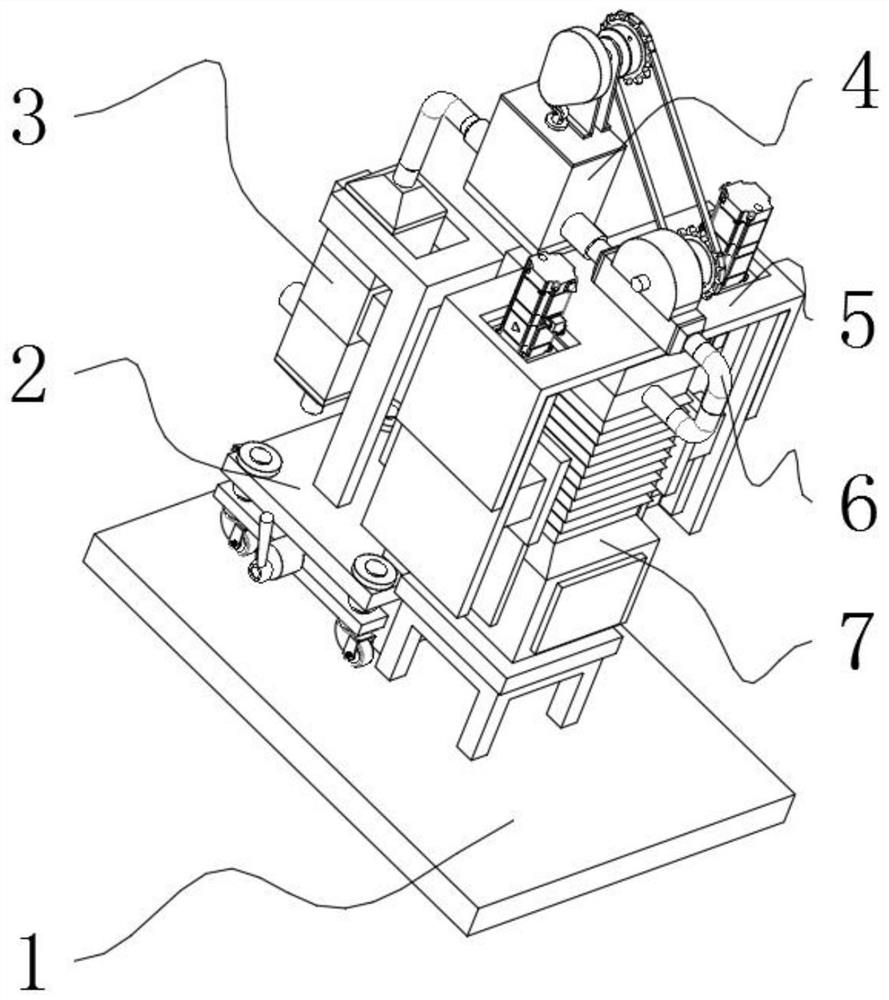

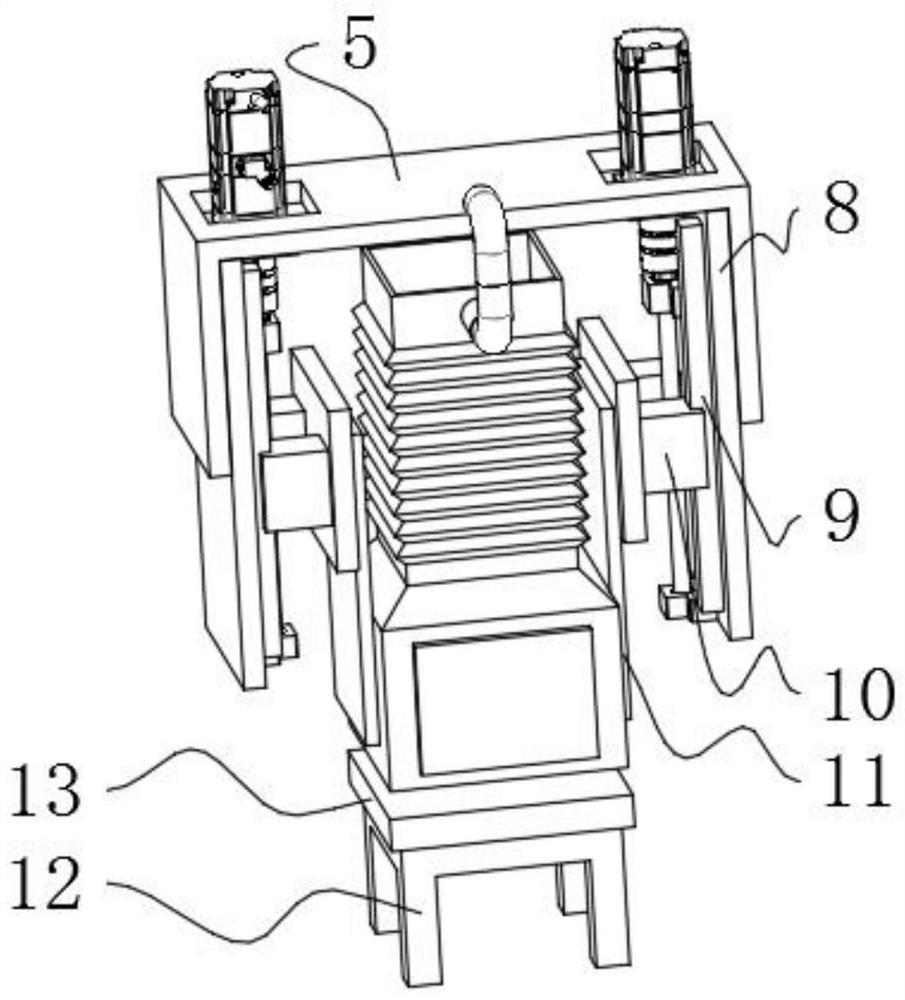

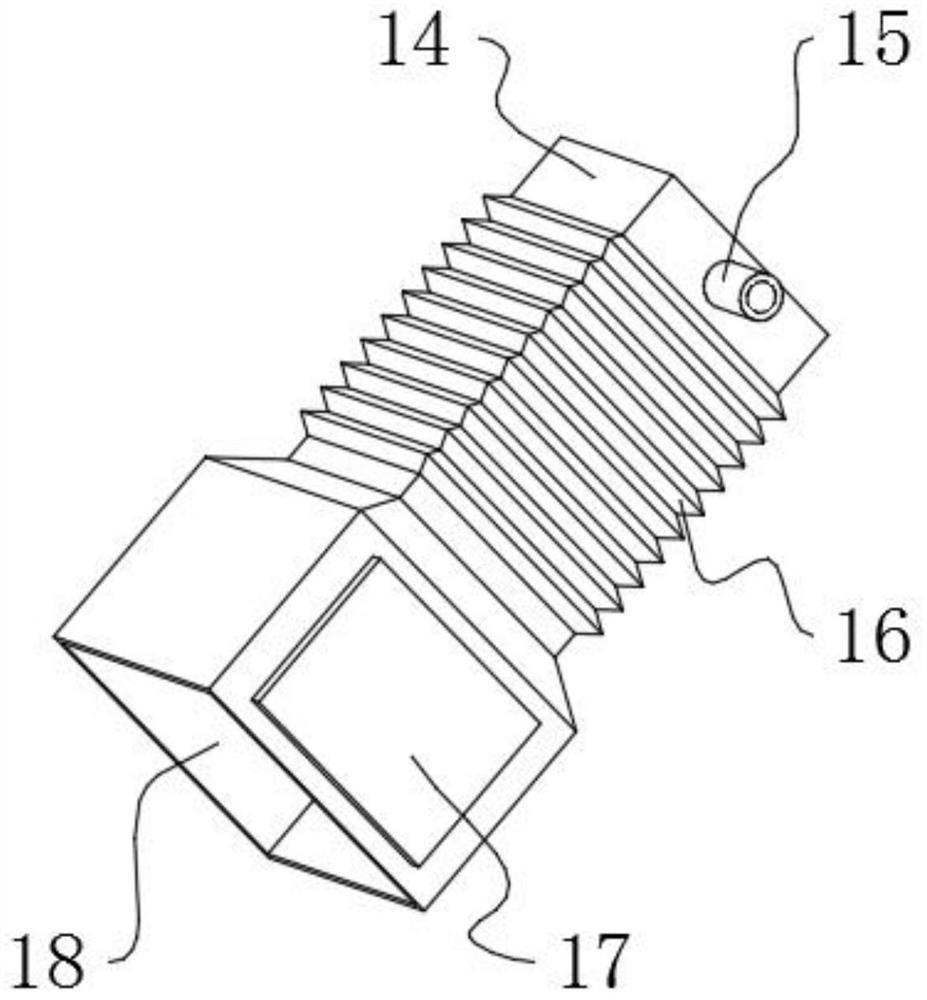

[0042] A welding machine with multiple collection and filtration mechanisms for welding fumes, such as Figure 1-9 As shown, it includes a bottom plate 1, the outer wall of the top of the bottom plate 1 is fixedly connected with a slide assembly 2, the top outer wall of the slide assembly 2 is fixedly connected with a filter assembly 3, the top outer wall of the slide assembly 2 is fixedly connected with a stand 22, and the stand 22 The outer wall of the top is fixedly connected with a beam 5, the outer wall of the top of the beam 5 is fixedly connected with an air suction assembly 4, and the inner wall of one side of the beam 5 is fixedly connected with an outer cover assembly 7; The side outer wall is fixedly connected to the inner wall of one side of the crossbeam 5, and the outer wall of one side of the slide rail 9 is connected to the outer wall of one side of the sticking board 8 by bolts. The outer wall of the top of the paste board 8 is fixedly connected with a lifting...

Embodiment 2

[0048] A kind of filtering method of the welding machine with welding fume multiple collection filter mechanism, such as Figure 1-9 As shown, the welding machine described in this embodiment is the welding machine in Example 1, and its method of use includes the following steps;

[0049] S1: gas delivery; the welding fume gas passes through the suction assembly 4 and enters the bundle tube 44;

[0050] S2: Preliminary ionization; the outer wall of the ionization chamber 43 drives box one 46 to start, and the discharge plate 47 ionizes the welding fume gas;

[0051] S3: deep filtration; the gas enters the filter chamber 42, and the swing motor drives the three filter plates 45 to swing to filter;

[0052] S4: Waste material settling; waste materials generated by filtration, including filter plate wear waste and welding smoke red waste, are discharged through falling;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com