UHPC dry-mixing stirring equipment

A technology of dry mixing and equipment, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of limited initial setting time and inability to meet long-distance transportation, etc., achieves high degree of automation and good mixing effect , high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described The embodiments are only some of the embodiments of the present invention, not all of them.

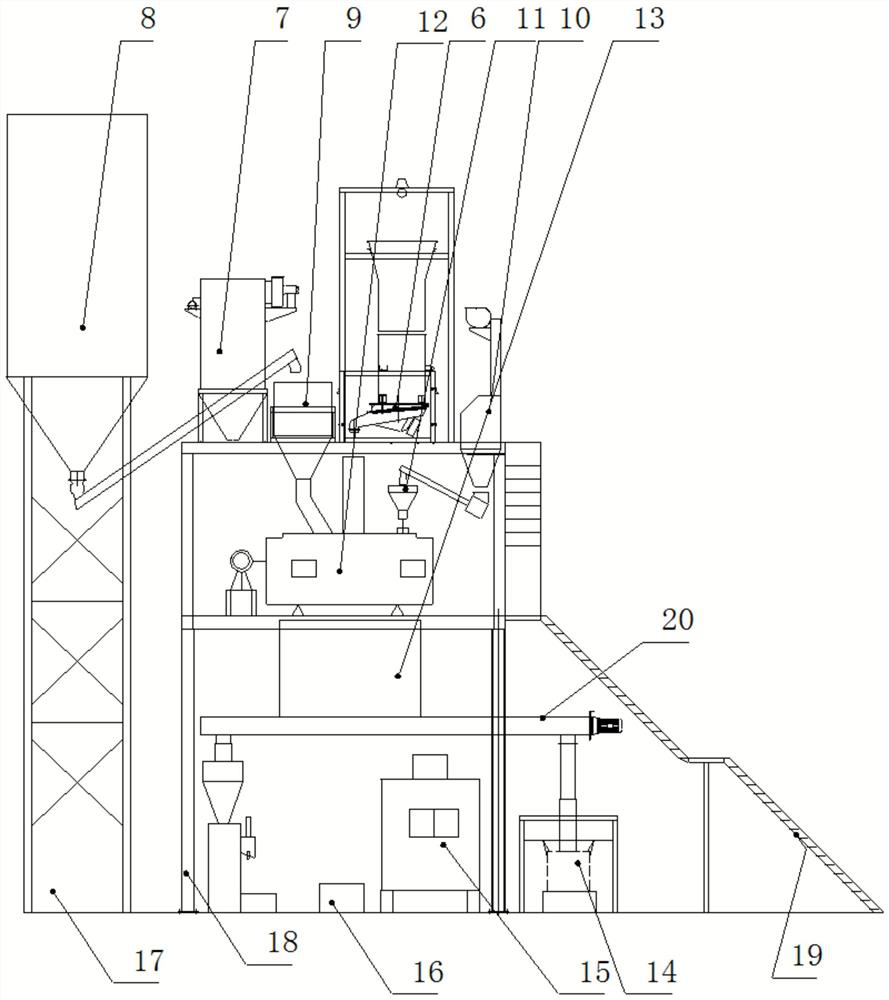

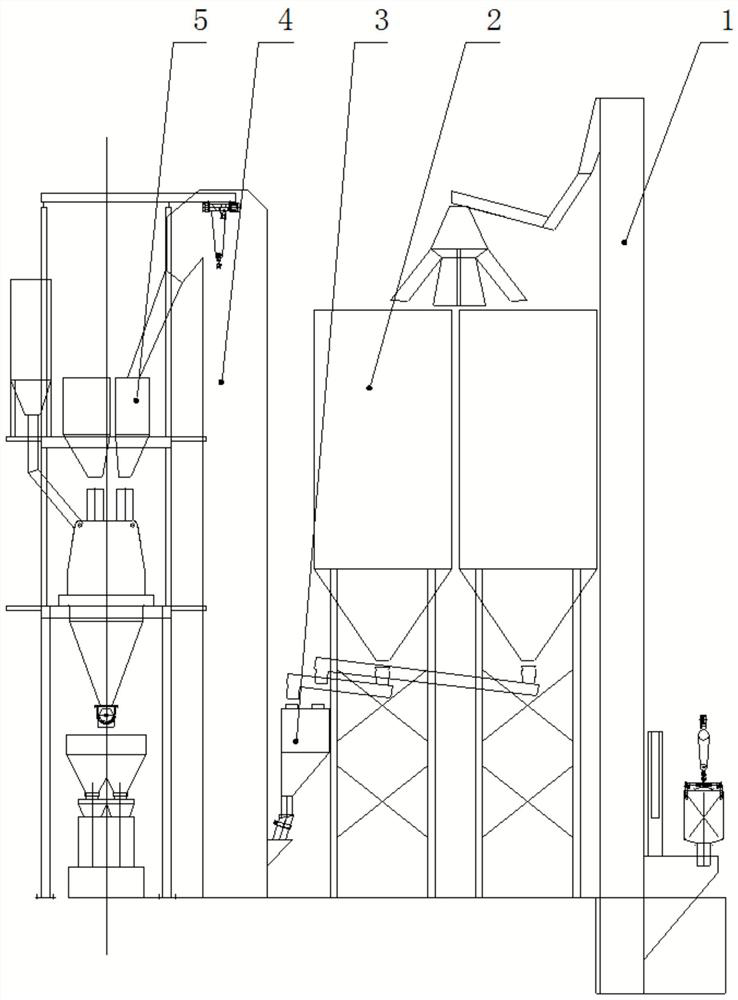

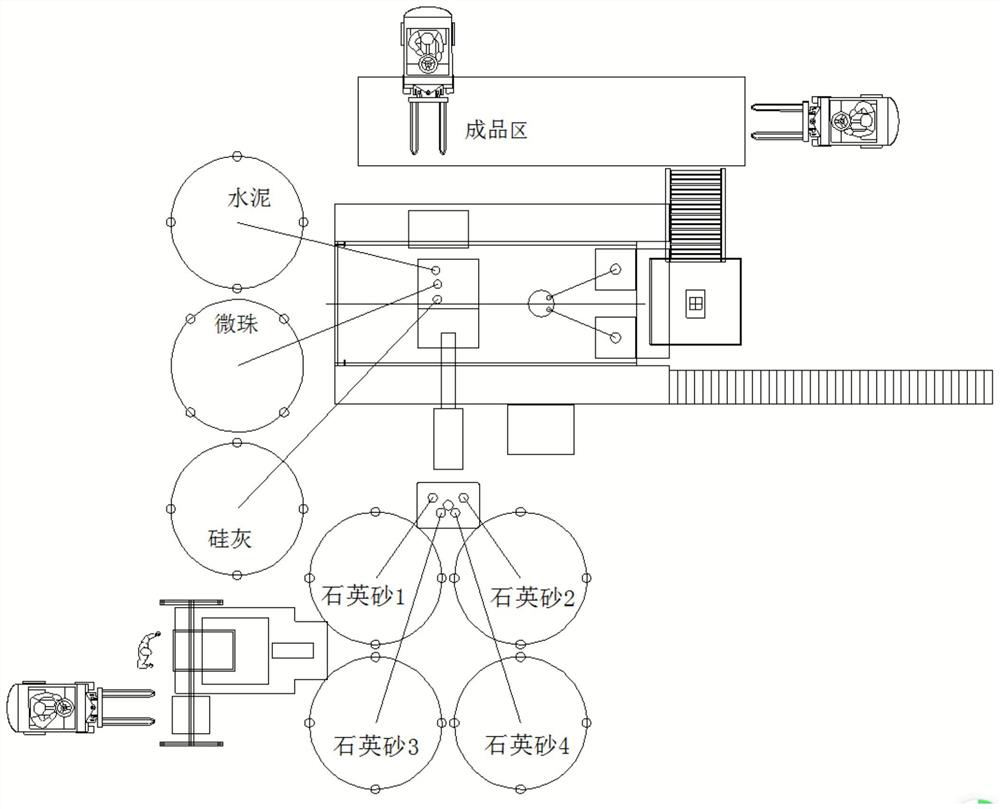

[0032] like figure 1 , 2 , 3, a UHPC dry mixing mixing equipment, including quartz sand feeding system 1, quartz sand storage system 2, quartz sand metering scale 3, quartz sand hoist 4, quartz sand storage bucket 5, steel fiber metering system 6. Main building dust removal system 7. Powder storage system 8. Powder metering system 9. Admixture storage system 10. Admixture metering system 11. Single horizontal shaft mixing host 12. Hopper 13. Finished product packaging system 14. Electrical control system , The gas system, the invention can realize t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap