Anti-blocking rapping device for coal dropping pipe of thermal power plant and using method thereof

A technology for rapping devices and coal drop pipes, which is applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., and can solve problems such as weakening the vibration force, reducing the functionality of the device, and reducing the environmental protection of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

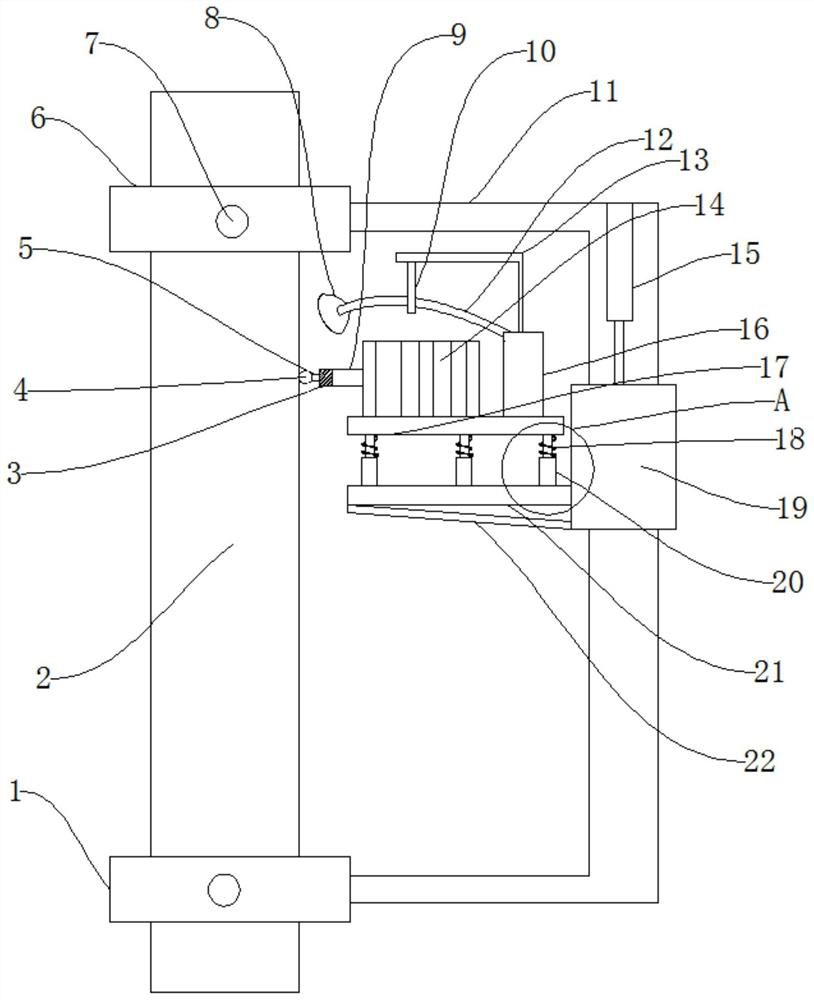

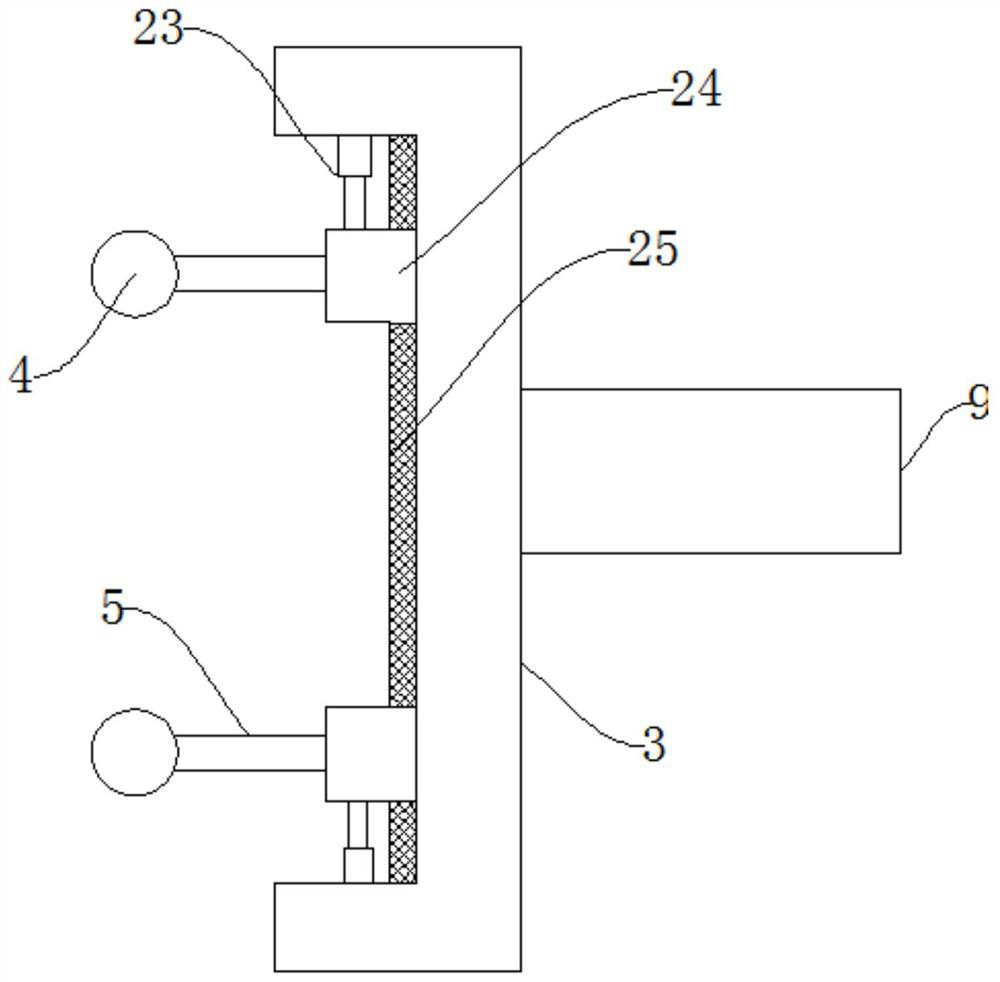

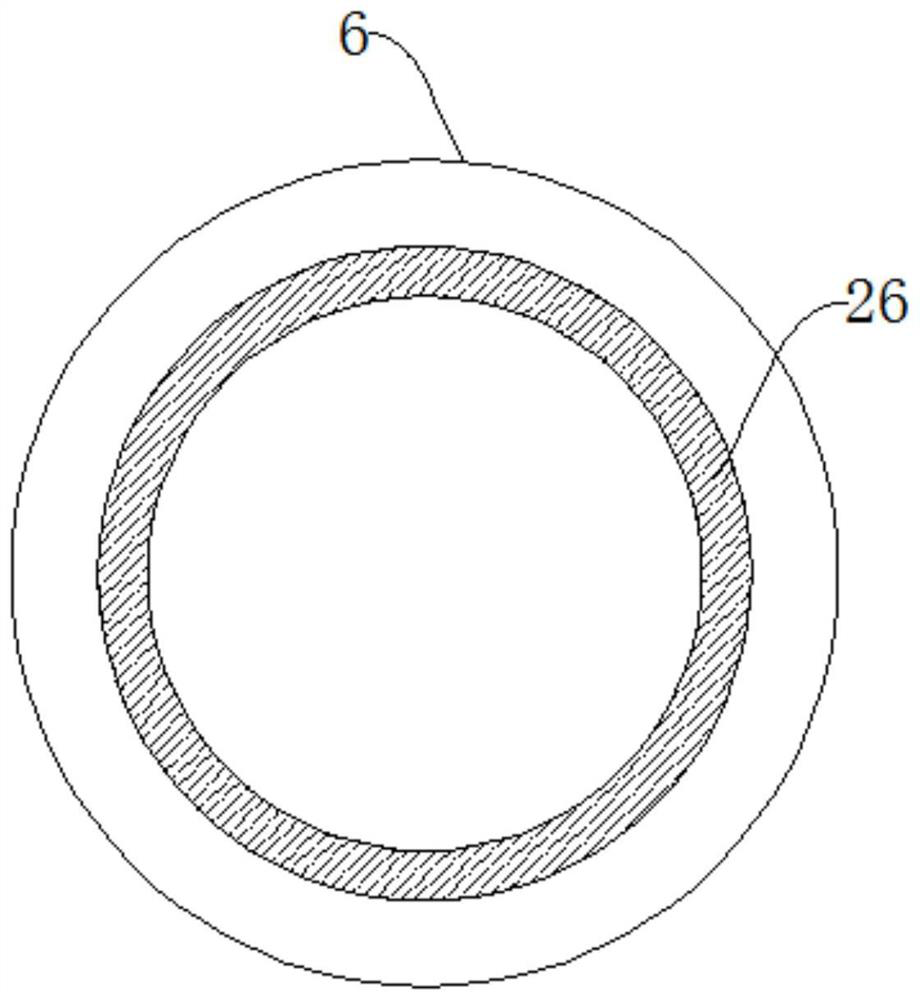

[0034] Such as Figure 1-Figure 4As shown, a kind of anti-blocking and rapping device of coal falling pipe in thermal power plant comprises coal falling pipe 2, upper fixing ring 6, lower fixing ring 1 and installation frame 11, said upper fixing ring is arranged on said coal falling pipe 2 6. The lower fixing ring 1 is arranged under the upper fixing ring 6, and rubber pads 26 are arranged on the inner walls of the upper fixing ring 6 and the lower fixing ring 1, and the upper fixing ring 6 and the lower fixing ring Fixing bolts 7 are arranged on one side wall of the fixing ring 1, the installation frame 11 is arranged between the upper fixing ring 6 and the lower fixing ring 1, and a sliding sleeve 19 is arranged on the installation frame 11, The top of the sliding sleeve 19 is provided with an electric push rod 15, the side wall of the sliding sleeve 19 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com