Cooling method for new energy automobile machining

A new energy vehicle and processing seat technology, which is applied in lighting and heating equipment, household appliances, household refrigeration devices, etc., can solve the problems of not having processing machinery and object workbench cooling, and having no device for emergency cooling, so as to achieve good heat dissipation effect, the effect of ensuring dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

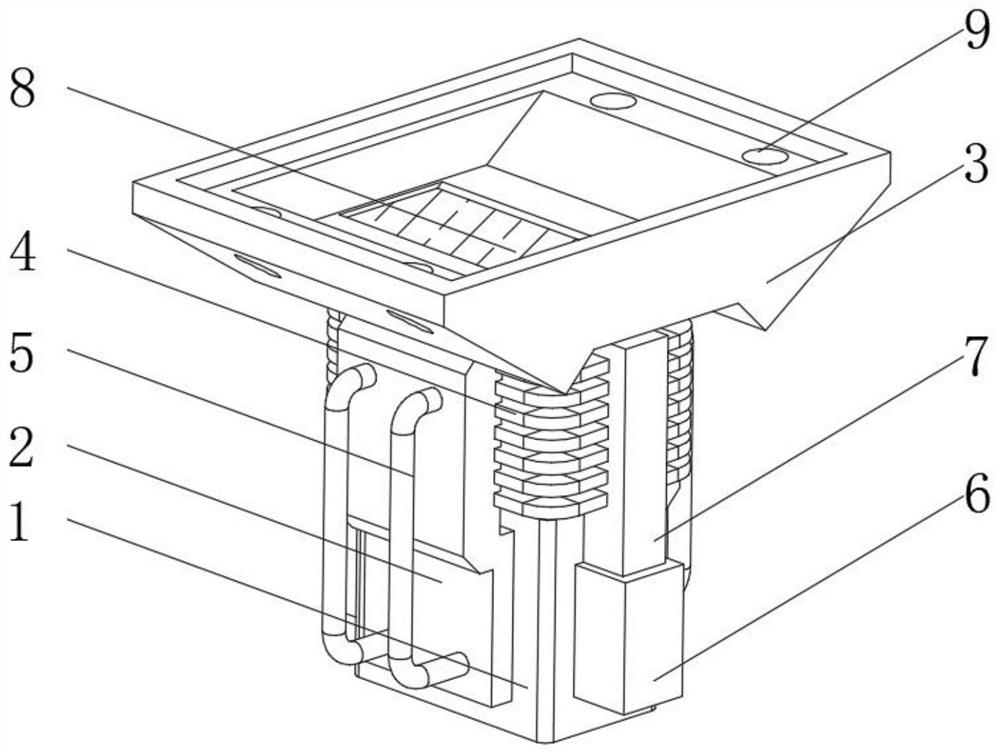

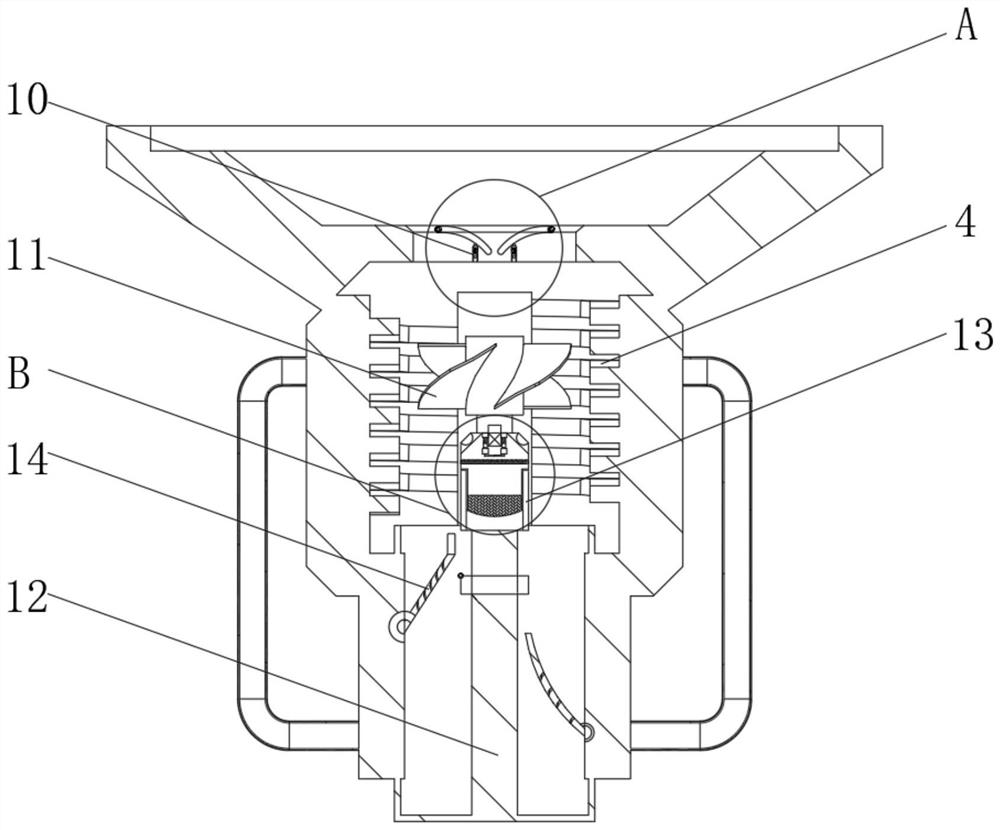

[0033] see Figure 1-5 , the present invention provides a technical solution: a cooling device for processing new energy vehicles, including a bottom shell 1, a heat conduction shell 2 is arranged on the outside of the bottom shell 1, and a heat dissipation fin tube 4 is arranged above the bottom shell 1, A cooling processing seat 3 is provided on the top of the connection heat conduction shell 2, and a water tank 6 is provided on the side of the bottom shell 1 adjacent to the connection heat conduction shell 2, and a connection reinforcement 7 is provided above the water tank 6, and an injection water pump is provided inside the water tank 6 to connect heat conduction The outer shell 2 is provided with a return liquid pipe 5, the bottom of the return liquid pipe 5 is connected with the water tank 6, the water outlet of the injection pump is connected with the water inlet of the heat dissipation fin pipe 4, and the cooling processing seat 3 is provided with a material drop-off ...

Embodiment example 2

[0041] A cooling method for processing new energy vehicles, comprising the following cooling steps:

[0042] S1: place the cooling equipment as a whole under the processing table, align the upper workbench and set it, insert the workbench above the part into the docking hole 9 of the cooling processing seat 3 through the installation rod, and complete the docking of the device;

[0043] S2: The upper processing table guides the heat of processing to the lower connected heat conduction shell 2 through the cooling processing seat 3, and the internal circulating water cools down through the cooling fin tube 4;

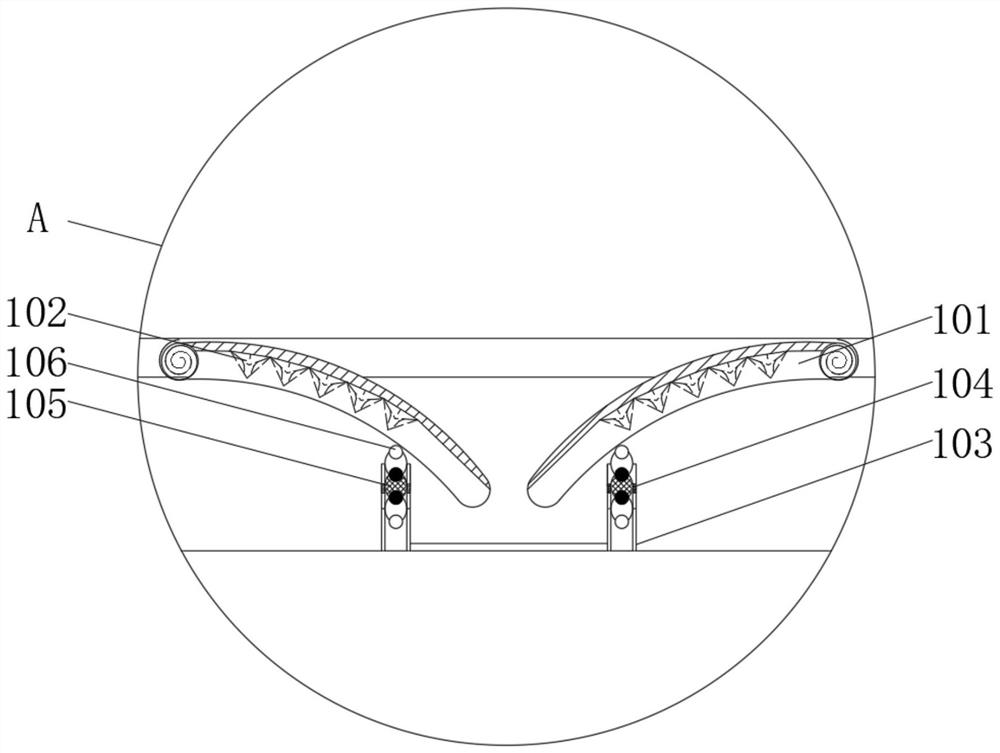

[0044] S3: The upper internal position adjustment device 10 will be used to limit the whereabouts of the processing residual materials above. When the weight is too large, or when there are many accumulated materials, the columnar electromagnet positioner 103 is pressed down at this time. When the energized contact column 105 is pressed down and does not contact the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com