Remote control and automatic tracking combined intelligent safety control method for tower crane

A tower crane, automatic tracking technology, applied in the direction of load hanging components, transportation and packaging, can solve problems such as large safety risks, achieve the effect of solving safety risks, avoiding safety risks, and meeting the needs of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

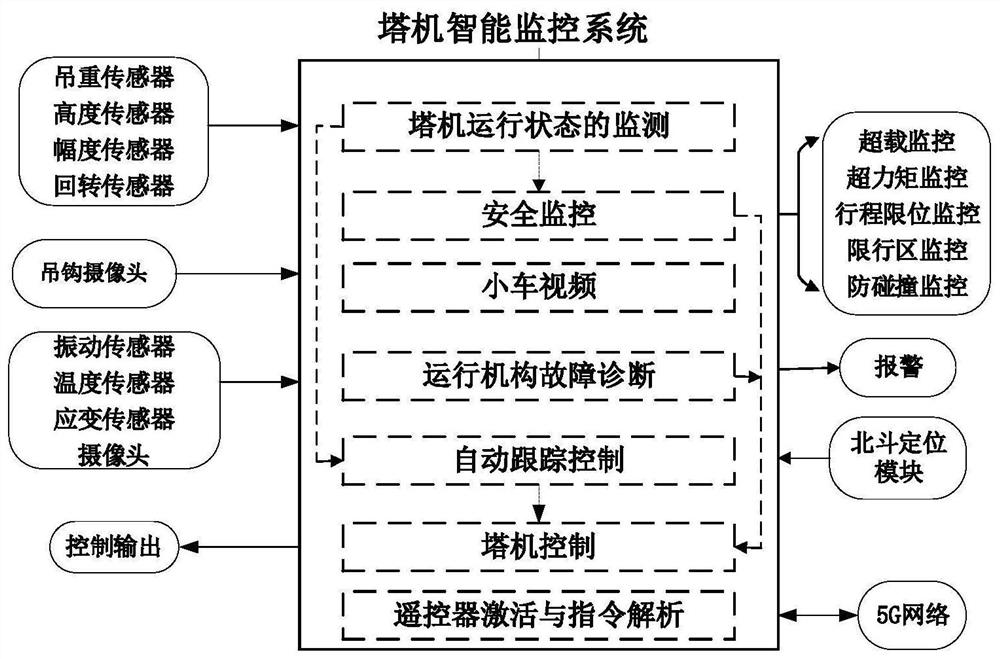

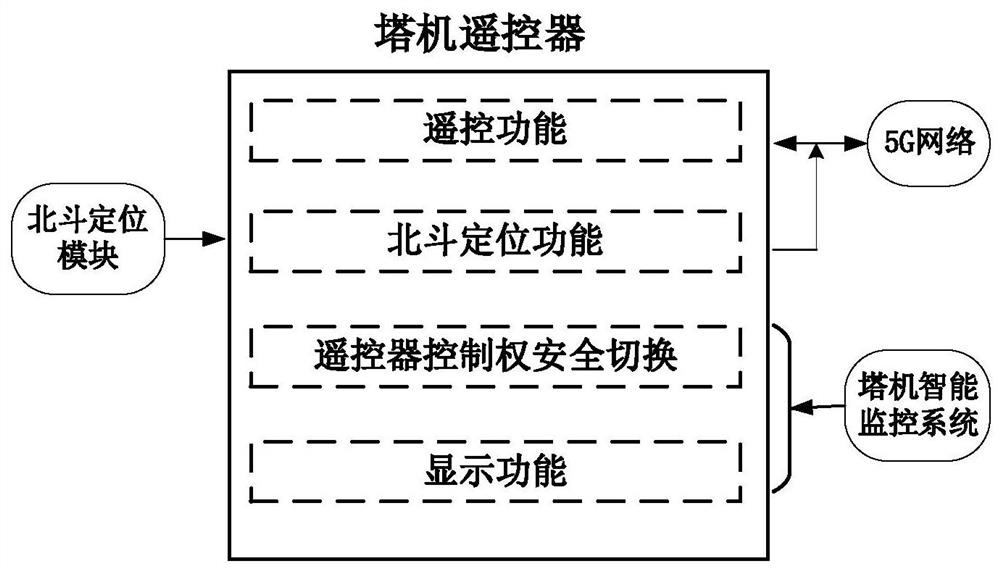

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

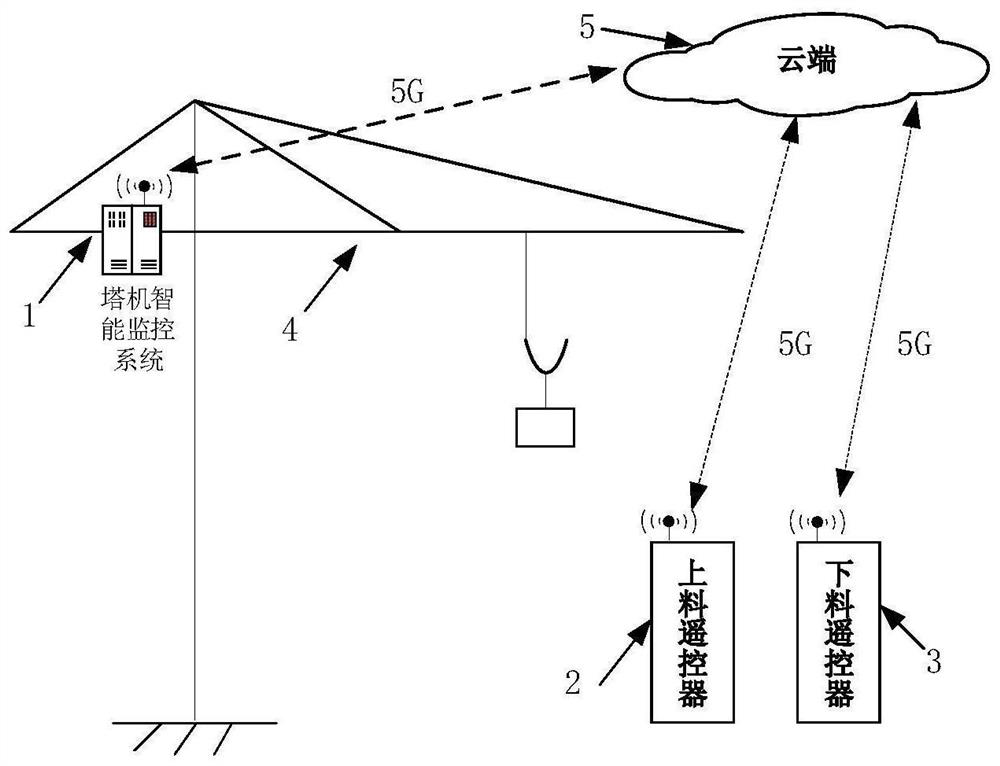

[0071] refer to Figure 5 , a construction site has 1 tower crane, a steel bar stockyard P1 and a steel structure stockyard P2. It needs to go back and forth between the two stock yards and the working surface. The tower crane is controlled by the method of the present invention, the tower crane intelligent monitoring system 1 is installed on the tower crane, and the two remote controllers of the tower crane are respectively located in the material yard and the construction work surface.

[0072] Assuming that the tower crane needs to transport the steel bars from the steel bar stockyard P1 to the construction work surface C, at this time, the loading remote control 2 is located at the steel bar stockyard P1, and the unloading remote control 3 is located at the construction work surface C, and the following operations are started,

[0073] Step 1. After the system initialization is completed, the tower crane is in the automatic tracking mode, and the two remote controllers of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com