Hydrogen production device

A technology for a hydrogen production device and a hydrogen generator, which is applied in the fields of hydrogen, hydrogen/syngas production, inorganic chemistry, etc., can solve the problems of low hydrogen production efficiency, large consumption of combustion catalysts, and single heating method, and achieve overall sealing performance. Good, various heating methods, high heat utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

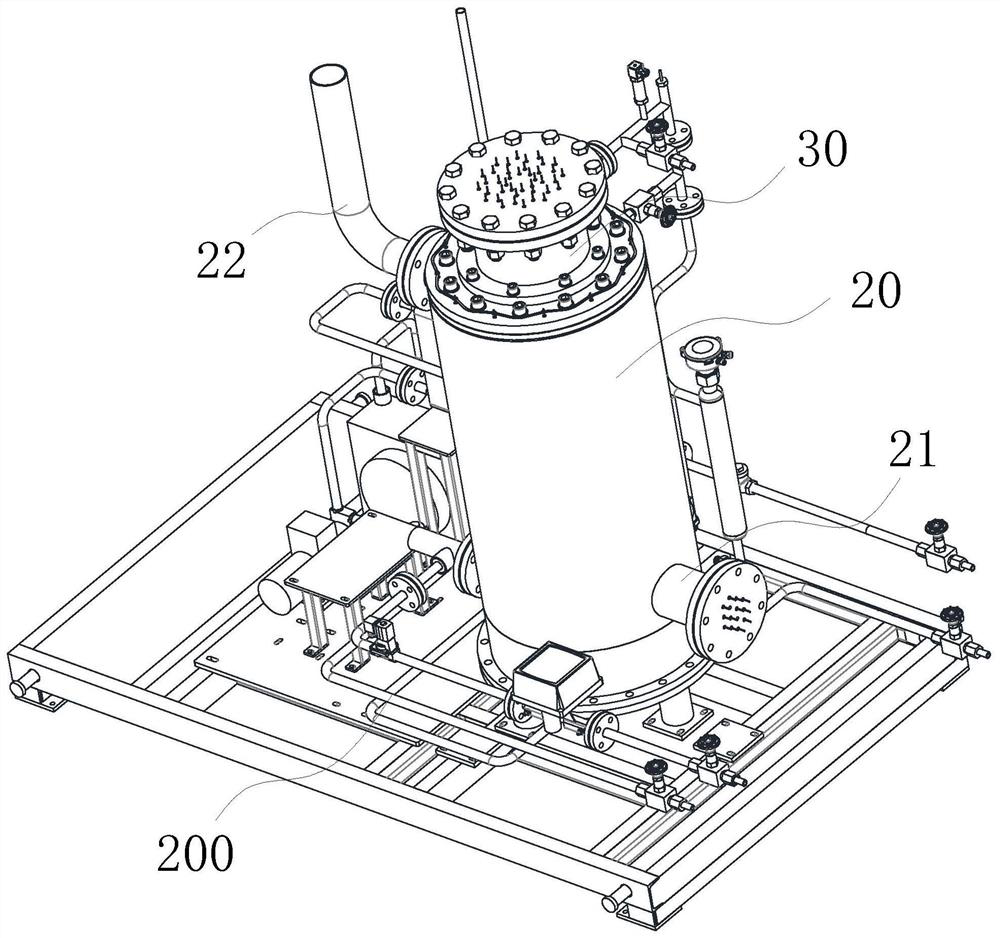

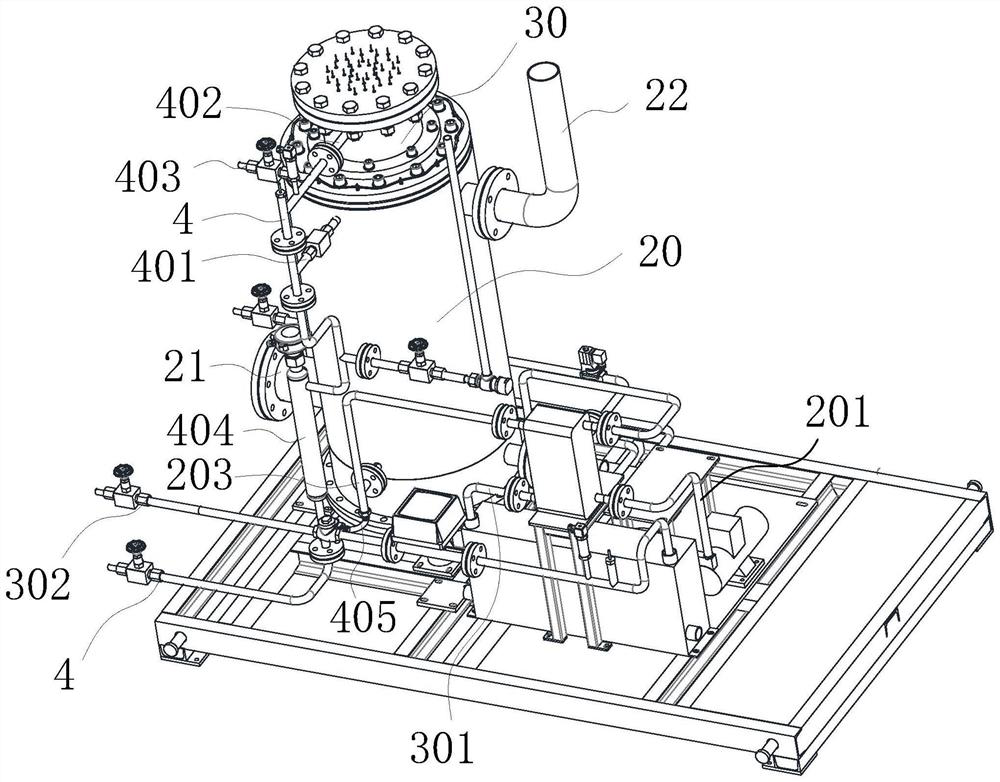

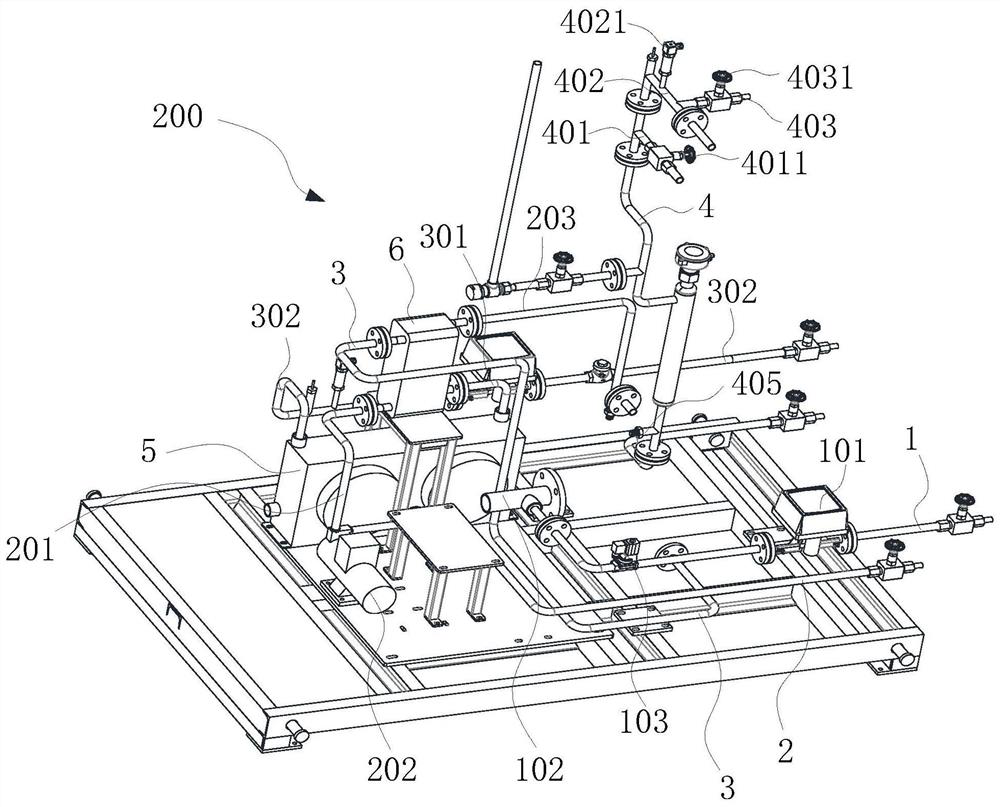

[0061] see Figure 5 , Figure 6 and Figure 7 , a hydrogen production device, comprising: a steam generator 20 for generating steam required for hydrogen production and a hydrogen generator 30 for generating hydrogen by reacting with the steam.

[0062] Specifically, the steam generator 20 includes an outer cylinder 23 and an inner cylinder 24 sleeved in the outer cylinder 23. The inner and outer cylinders 23 are both heat-insulating shells. Cavity 60, the side of the outer cylinder 23 is provided with an electric heating port communicating with the heating chamber 50; the heating chamber 50 has built-in a plurality of combustion catalyst tubes 51 communicating with the external exhaust gas; , the steam pipe 62 is used to transport the steam generated in the steam generator 20; the overheating chamber 60 communicates with one end of the combustion catalyst pipe 51; The hydrogen production catalyst reacts to generate hydrogen; wherein, a combustion catalyst is arranged in t...

Embodiment 2

[0071] This embodiment is a further optimization scheme on the basis of embodiment 1:

[0072] Such as Figure 14 As shown, fins 53 are distributed on the surface of the combustion catalyst tube 51 to increase the heat dissipation area, improve the transfer of heat generated by the combustion catalyst tube 51 to the liquid, and accelerate the evaporation of the liquid.

[0073] Further, a porous partition 52 is arranged in the combustion catalyst tube 51 to form an accommodating space, so that the combustion catalyst is placed in the combustion catalyst tube 51, and the porous partition 52 is distributed with air holes smaller than the diameter of the combustion catalyst, which is convenient for entering the combustion catalyst tube 51. The exhaust gas inside reacts with the combustion catalyst. Of course, one or more porous partitions 52 in the combustion catalyst tube 51 can be provided and distributed in the combustion catalyst tube 51 at intervals. The porous partition 52...

Embodiment 3

[0075] This embodiment can be combined with Implementation 1-2 separately or simultaneously, as a further improvement:

[0076] Such as Figure 12 As shown, the steam generator 20 also includes a base 40 with an exhaust gas inlet cavity 42 inside, and at least one exhaust gas inlet 41 is provided on one side of the exhaust gas inlet cavity 42 for communicating with the external exhaust gas; see Figure 7 and Figure 11 , the overheating chamber 60 , the heating chamber 50 and the exhaust gas inlet chamber 42 are stacked in sequence in the vertical direction, and a partition 25 is arranged between them. A partition 25 is arranged between the overheating chamber 60 , the heating chamber 50 , and the exhaust gas intake chamber 42 that are successively stacked in the vertical direction, so that a relative buffer area is formed between each layer, for example, a partition is arranged in the exhaust gas intake chamber 42 25. When the exhaust gas enters the exhaust gas intake cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com