Circular mould and sludge granulator

A granulator and ring die technology, used in sludge treatment, die extrusion granulation, fixed/solidified sludge treatment, etc., can solve the problem of inappropriate sludge raw material granulation, etc. Abrasiveness, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

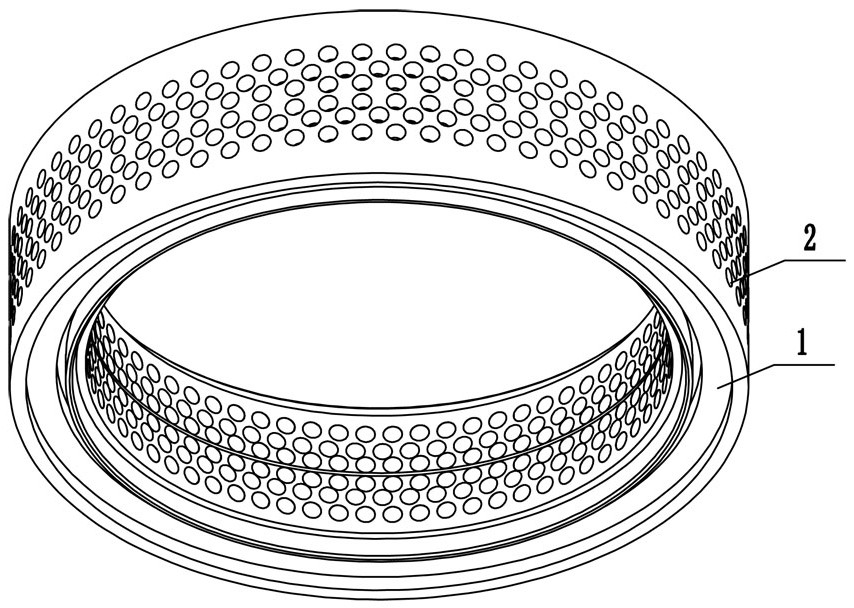

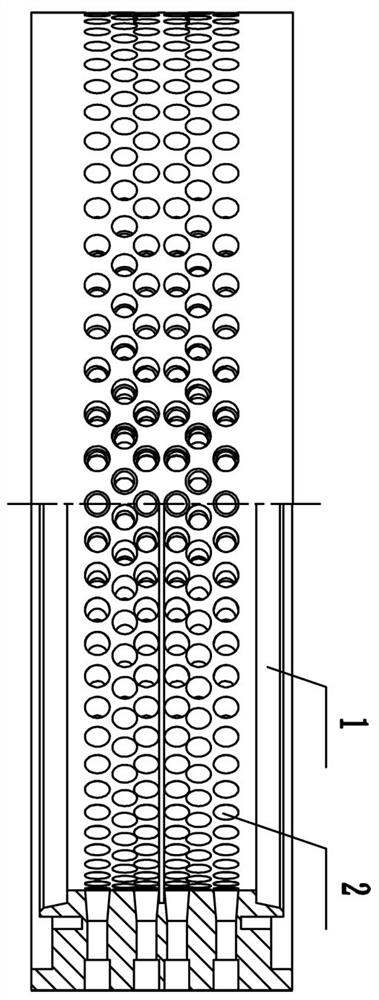

[0032] Such as Figure 1~Figure 5 As shown, a ring die includes a ring die body 1 and a die hole 2, the ring die body 1 is a torus structure made of cold-work die steel, and the Rockwell hardness of the ring die body 1 is HRC20-70;

[0033] Compared with the commonly used stainless steel ring die, the ring die is made of cold work die steel with a Rockwell hardness of HRC20-70, which has good wear resistance, corrosion resistance and toughness, and is in line with the characteristics of sludge raw materials. For sludge granulation operations.

[0034] The upper and lower sides of the ring die body 1 form two symmetrical die hole areas, each of which is provided with a plurality of rows of die holes 2 that are dislocated up and down, and each row of die holes 2 is several One, and the ring direction are all set on the ring die body 1.

[0035] In this embodiment, the opening ratio of the die hole 2 on the ring die body 1 is in the range of 20-60%, and the three adjacent die h...

Embodiment 2

[0050] Such as Figure 6 As shown, this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the depth L of the die hole 2 is 80 mm, that is, the thickness of the ring die body 1 is 80 mm, and the thicker the ring die body 1 , The deeper the die hole 2 and the smaller the hole diameter, the greater the resistance of the hole wall and the firmer the extrusion of the material;

[0051] Through multiple tests, for sludge raw materials with a moisture content of 8%-25%, it is more appropriate to use a ring die body 1 with a thickness of 80mm, which can obtain high-quality sludge particles and is not easy to block the die hole 2 at the same time.

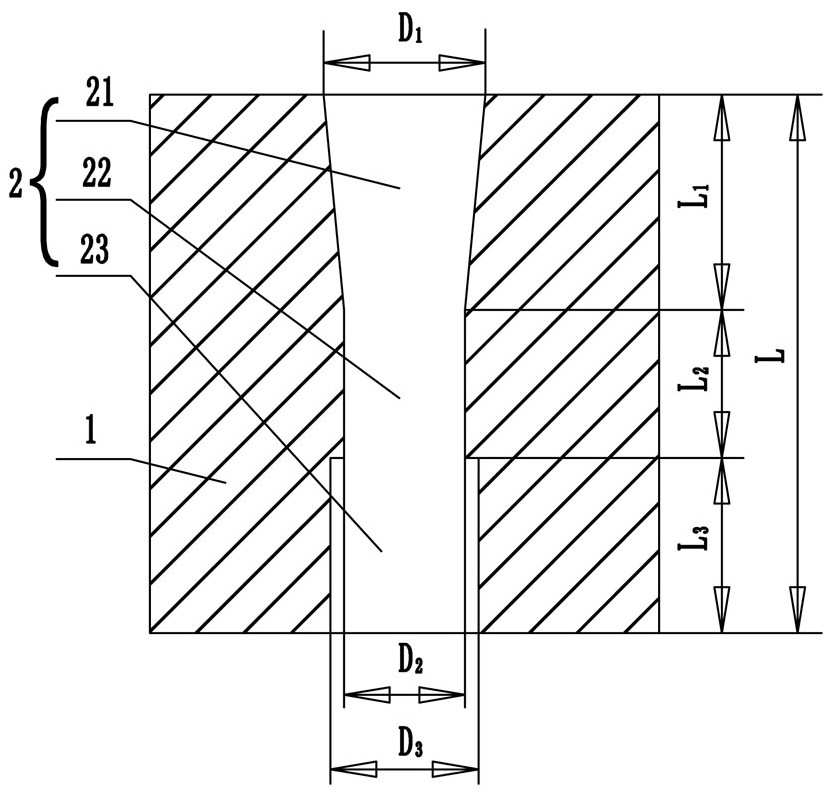

[0052] In this embodiment, the length of the pre-compression section 21 is L 1 is 32mm, and the diameter of the large diameter end is D 1 24mm, length L of forming section 22 2 22mm, diameter D 2 18mm, release section 23 length L 3 26mm, diameter D 3 22mm;

[0053] The...

Embodiment 3

[0057] Such as Figure 7 As shown, the present embodiment is basically the same as Embodiment 2, and the similarities will not be repeated. The difference is that the depth L of the die hole 2 is 80mm, and the length L of the pre-compression section 21 1 35mm, the diameter of the large diameter end is D 1 26mm, length L of forming section 22 2 25mm, diameter D 2 20mm, release section 23 length L 3 20mm, diameter D 3 The ring die body 1 is made through the above parameters and applied to production, and columnar sludge particles with a diameter of φ20mm can be obtained.

[0058] The present invention optimizes the structural parameters of the die hole 2 to make it suitable for the granulation of sludge raw materials, improves the smooth discharge of sludge, is beneficial to the molding of the product, and ensures its molding quality. At the same time, it also makes the ring die body 1 The service life is extended and the cost of use is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com