Containing type kitchen waste solid aerobic fermentation equipment and fermentation process

A technology of food waste and aerobic fermentation, which is applied in the direction of organic fertilizer equipment, preparation and application of organic fertilizer, etc., can solve problems such as complex environment and water source pollution in the processing process, improve processing capacity and efficiency, and solve secondary problems. Pollution and odor problems, the effect of realizing green and safe disposal of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

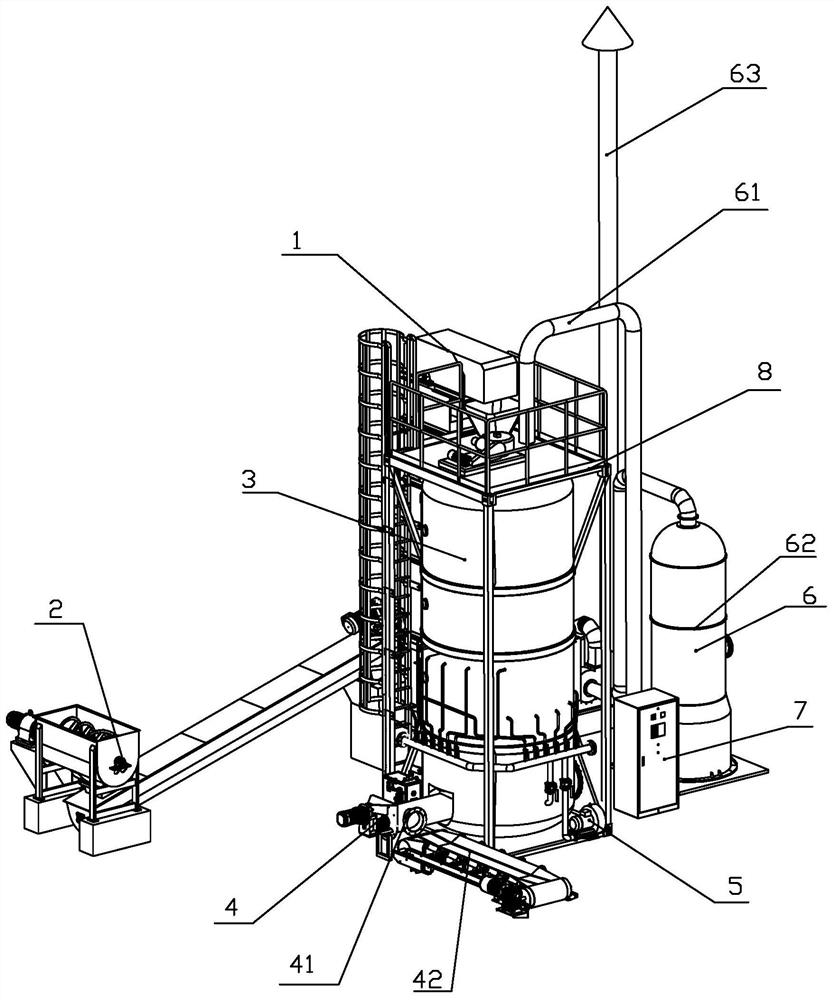

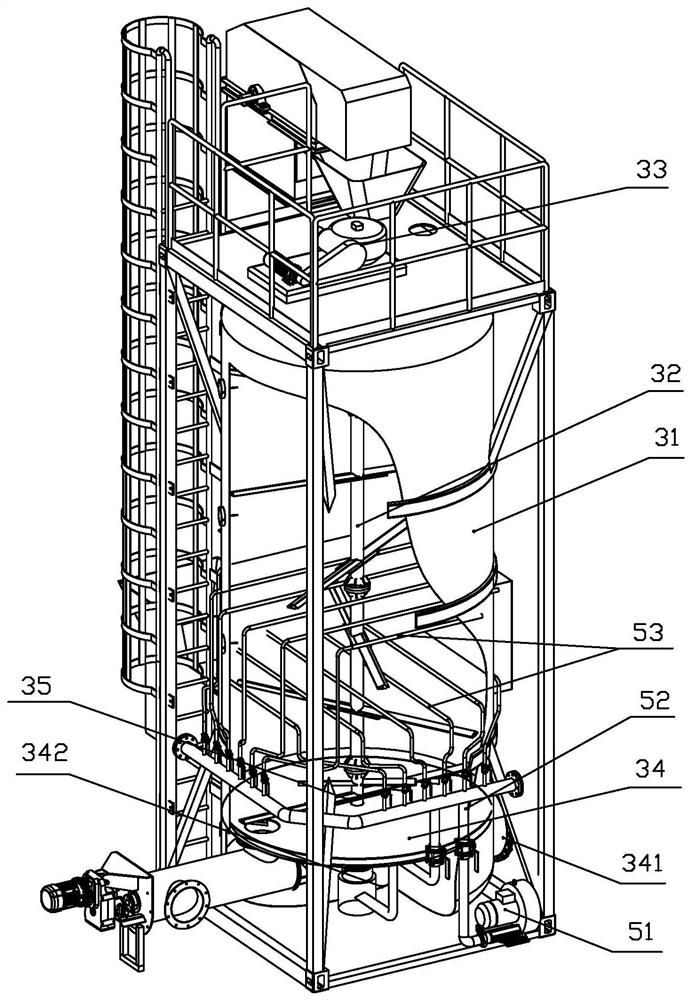

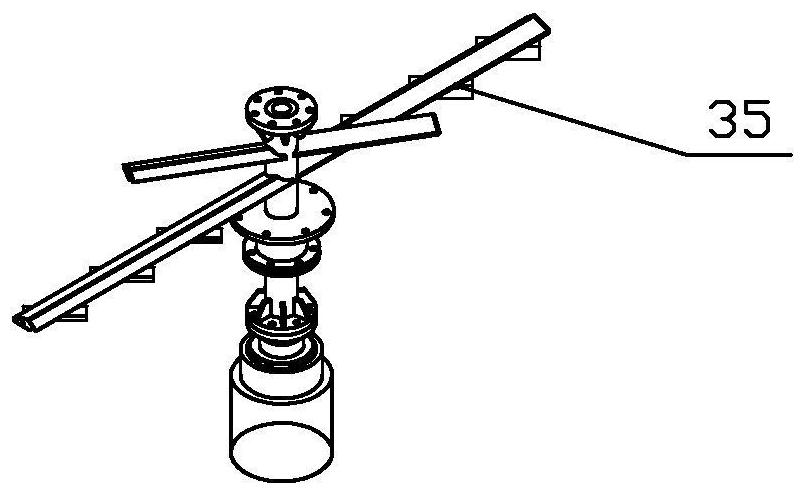

[0038] Specific implementation mode one: combine Figure 1-8 Describe this embodiment, an inclusive solid-state aerobic fermentation equipment for food waste, which includes a feeding device 1, a mixing device 2, a fermentation device 3, a discharging device 4, an air supply and heat exchange device 5, and a deodorizing device 6 and control device 7,

[0039] The fermentation raw materials are mixed through the mixing device 2, and the mixed material is sent into the fermentation device 3 through the feeding device 1 for fermentation. Oxygen supply and heating to the interior of the fermentation device 3 are realized, the deodorization device 6 communicates with the fermentation device 3, the purification and discharge of the odor in the fermentation device 3 is realized through the deodorization device 6, and the discharge device 4 is connected to the bottom of the fermentation device 3 In the lower part, the fermentation product is discharged through the discharge device 4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com