Steel wire rod for 2000 MPa-grade spring and production method of wire rod

A production method and wire rod technology, applied in the field of spring wire rod and its production, 2000MPa spring wire rod, can solve the problems of harsh service conditions, uneven springs, poor purity, etc., to achieve purity optimization, gold Optimized phase structure and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

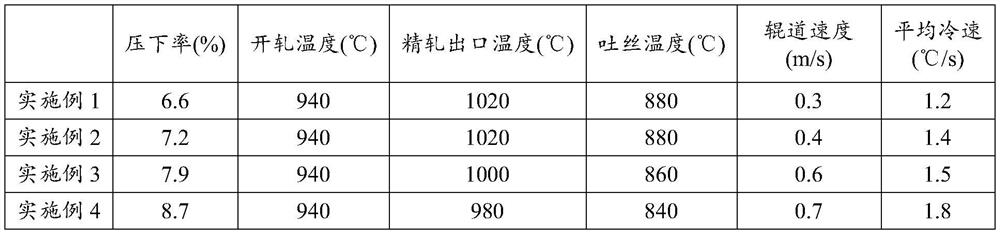

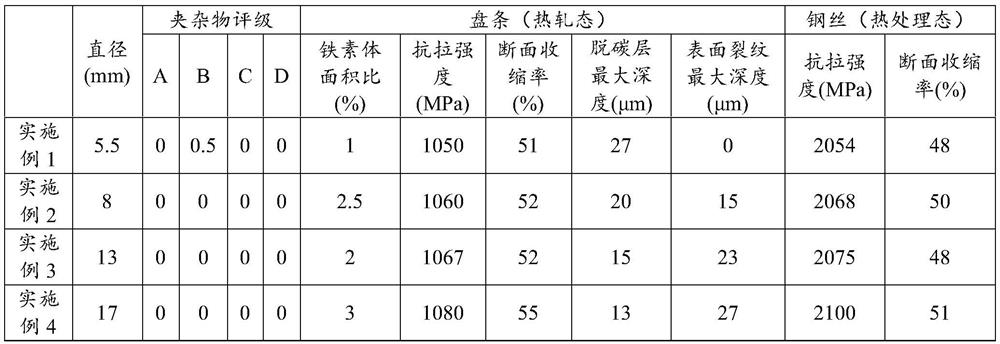

[0031] The technical solution of the present invention will be further introduced below in conjunction with specific embodiments, but the scope of protection is not limited to the description.

[0032] This embodiment provides a wire rod for high-strength springs, especially a wire rod for manufacturing 2000MPa-level springs, that is, the wire rod can be prepared into 2000MPa-level springs through known existing spring preparation processes.

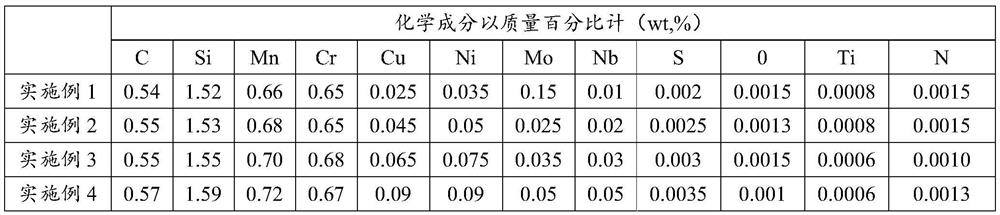

[0033] Specifically, the chemical composition of the wire rod is calculated by mass percentage: C: 0.53-0.57%, Si: 1.51-1.59%, Mn: 0.65-0.72%, Cr: 0.63-0.7%, Cu: 0.01-0.1% , Ni:0.01~0.1%, Mo:0.01~0.05%, Nb:0.01~0.05%, S≤0.005%, O≤0.002%, Ti≤0.001%, N≤0.002%, the balance is Fe and unavoidable Impurities.

[0034] The design of the chemical composition of the wire rod in the present invention is to design the content of various elements without adding or adding less precious metals and rare earth elements, so as to realize the mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com